Content .. 1143 1144 1145 1146 ..

Infiniti FX35, FX50 (S51). Manual - part 1145

ELECTRICAL LEAK DETECTOR

HA-93

< PERIODIC MAINTENANCE >

[VK50VE]

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

c.

Intake door position: Recirculation

d.

Temperature setting: Max. cold

e.

Fan speed: High

9.

Run engine at 1,500 rpm for at least 2 minutes.

10. Stop the engine and perform leakage check again, steps 4 – 6.

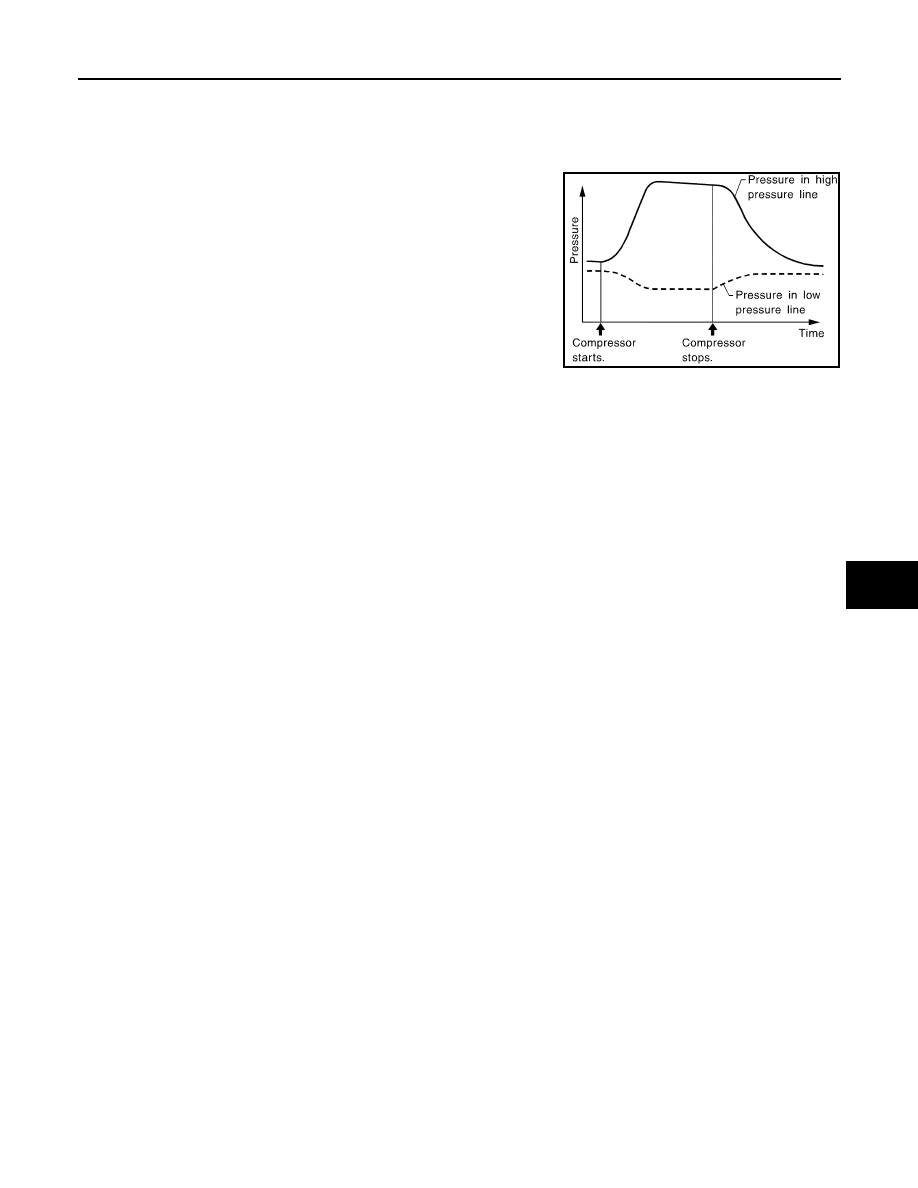

Refrigerant leakages should be checked immediately after stop-

ping the engine. Begin with the leak detector at the compressor.

The pressure on the high-pressure side drops gradually after

refrigerant circulation stops and pressure on the low-pressure

side rises gradually, as shown in the graph. Some leakages are

more easily detected when pressure is high.

11. Check recovery/recycling recharging equipment gauges before connecting recovery/recycling recharging

equipment to vehicle. No refrigerant pressure should be displayed. Recover refrigerant from equipment

lines if pressure is displayed, and then check refrigerant purity.

12. Confirm refrigerant purity in supply tank using recovery/recycling recharging equipment and refrigerant

identifier.

13. Confirm refrigerant purity in vehicle A/C system using recovery/recycling recharging equipment and refrig-

erant identifier.

14. Discharge A/C system using approved refrigerant recovery equipment. Repair the leaking fitting or com-

ponent if necessary.

15. Evacuate and recharge A/C system and perform the leakage test to confirm no refrigerant leakages.

16. Perform A/C performance test to ensure system works normally.

SHA839E