Content .. 1133 1134 1135 1136 ..

Infiniti FX35, FX50 (S51). Manual - part 1135

HEATER & COOLING UNIT ASSEMBLY

HA-53

< REMOVAL AND INSTALLATION >

[VQ35HR]

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

HEATER & COOLING UNIT ASSEMBLY

HEATER & COOLING UNIT ASSEMBLY : Removal and Installation

INFOID:0000000005249920

REMOVAL

1.

Set the temperature at 18.0

°

C (60

°

F).

2.

Disconnect the battery cable from the negative terminal.

3.

Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

4.

Drain engine coolant from cooling system. Refer to

5.

Remove cowl top cover. Refer to

6.

Remove engine cover. Refer to

.

7.

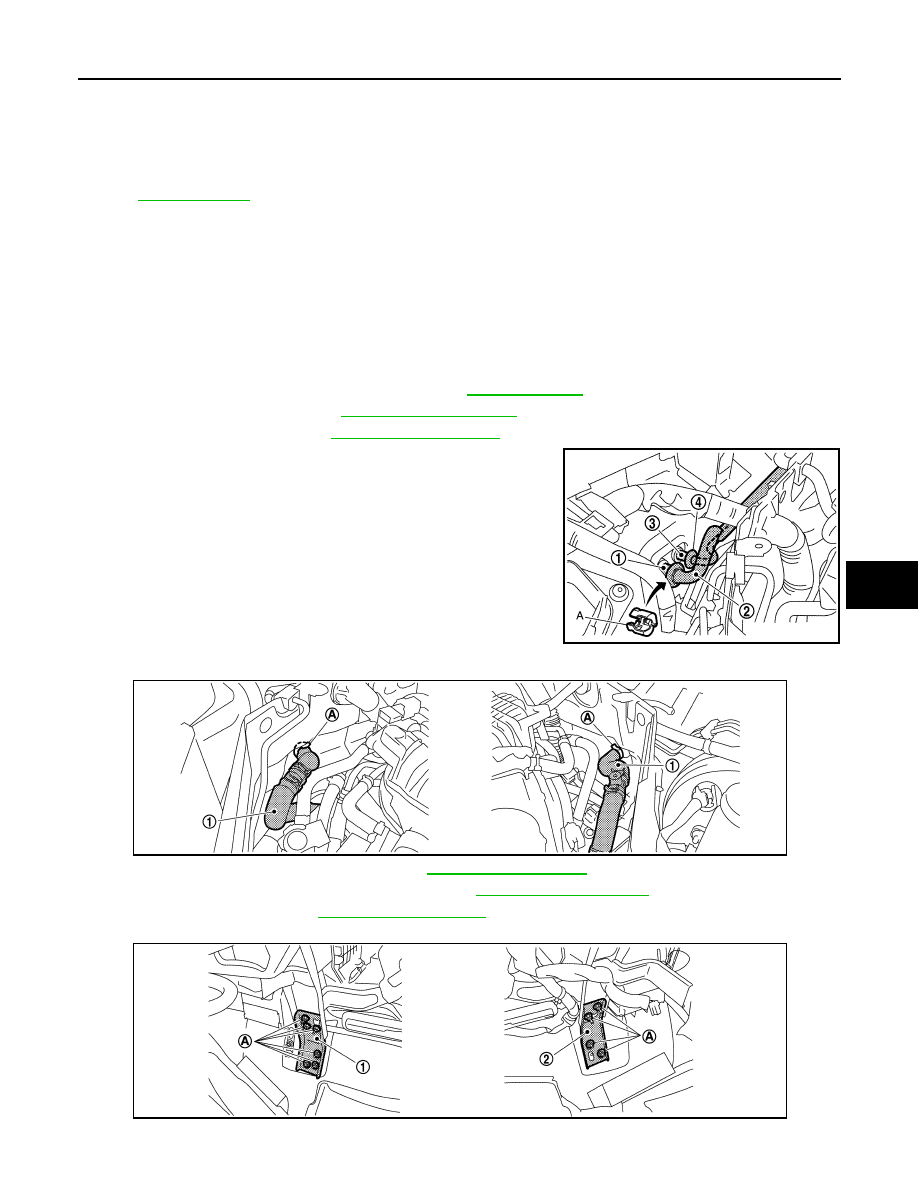

Disconnect one-touch joint between low-pressure pipe 1 (1) and

low-pressure pipe 2 (2) with disconnector (SST: 9253089916)

(A).

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

8.

Disconnect one-touch joint between high-pressure pipe 1 (4)

and high-pressure pipe 2 (3) with disconnector (SST:

9253089908).

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

9.

Remove clamps (A), and then disconnect heater hoses (1).

10. Remove instrument panel assembly. Refer to

11. Remove defroster nozzle and adaptor duct. Refer to

.

12. Remove blower unit. Refer to

13. Remove mounting nuts (A), and then remove instrument stay (left) (1) and instrument stay (right) (2).

14. Disconnect drain hose from heater & cooling unit assembly.

49.

Foot door (right)

50.

J-nut

51. Max. cool door lever

52.

Defroster door lever

53.

Defroster door link

54. Max. cool door link

55.

Intake sensor

56.

Intake sensor bracket

57. Air mix door motor (passenger side)

58.

Air mix door adapter

59.

Heater & cooling unit case (right)

60. Max. cool door (right)

61.

Max. cool door (left)

62.

Air mix door (Slide door)

Refer to

for symbols in the figure.

JSIIA1269ZZ

JSIIA1306ZZ

JPIIA0659ZZ