Content .. 1126 1127 1128 1129 ..

Infiniti FX35, FX50 (S51). Manual - part 1128

REFRIGERANT

HA-25

< PERIODIC MAINTENANCE >

[VQ35HR]

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

PERIODIC MAINTENANCE

REFRIGERANT

Collection and Charge

INFOID:0000000005249896

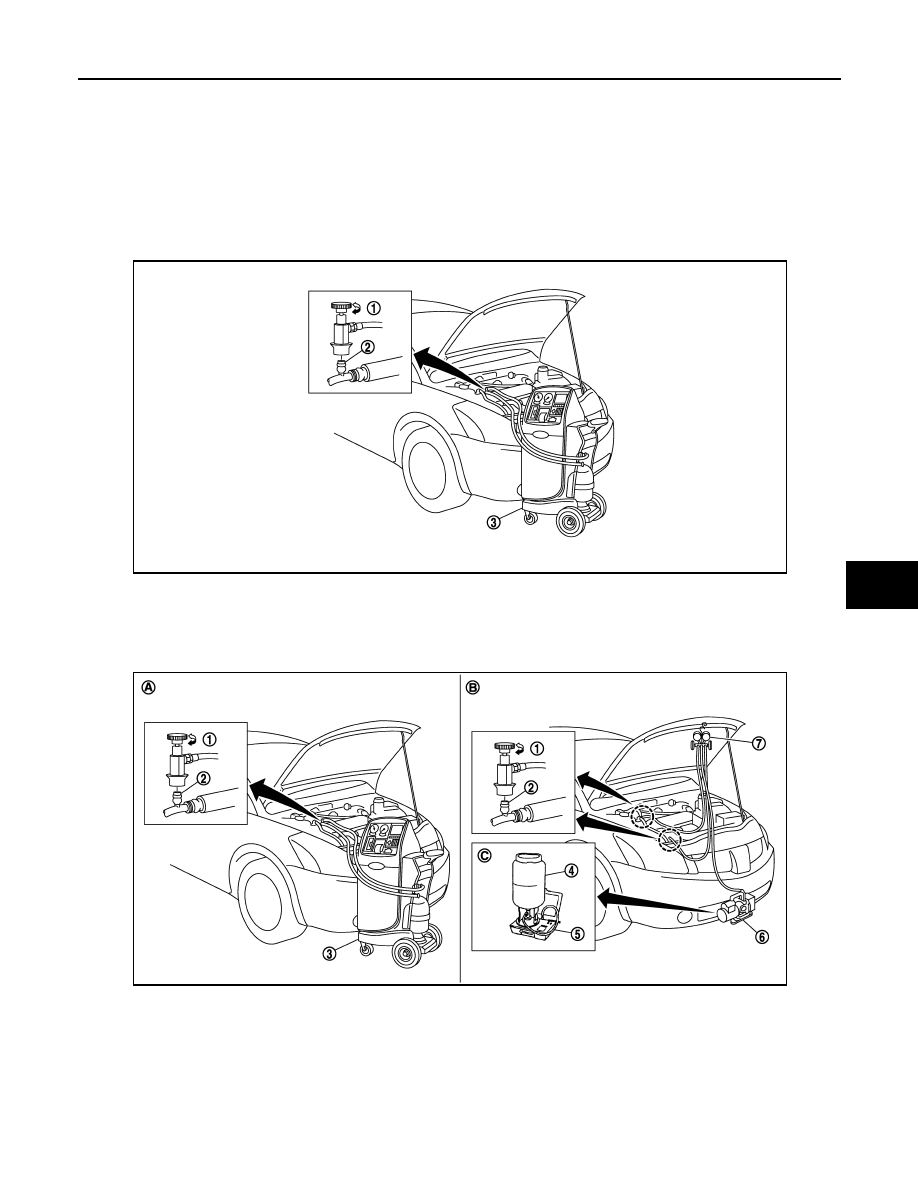

SETTING OF SERVICE TOOLS AND EQUIPMENT

Discharging Refrigerant

Evacuating System and Charging Refrigerant

Procedure

1.

Shut-off valve

2.

A/C service valve

3.

Recovery/recycling recharging

equipment

JSIIA0238ZZ

1.

Shut-off valve

2.

A/C service valve

3.

Recovery/recycling recharging

equipment

4.

Refrigerant container (HFC-134a)

5.

Weight scale (J-39650)

6.

Vacuum pump (J-39649)

7.

Manifold gauge set (J-39183)

A.

Preferred (best) method

B.

Alternative method

C.

For charging

JSIIA0239ZZ