Content .. 1123 1124 1125 1126 ..

Infiniti FX35, FX50 (S51). Manual - part 1125

PRECAUTIONS

HA-13

< PRECAUTION >

[VQ35HR]

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

requirements of SAE J-2210 [HFC-134a (R-134a) recycling equipment], or J-2209 [HFC-134a (R-134a)

recovery equipment]. Ventilate work area before resuming service if accidental system discharge

occurs. Additional health and safety information may be obtained from refrigerant and lubricant

manufacturers.

• Never release refrigerant into the air. Use approved recovery/recycling recharging equipment to cap-

ture the refrigerant each time an air conditioning system is discharged.

• Wear always eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

• Never store or heat refrigerant containers above 52

°

C (126

°

F).

• Never heat a refrigerant container with an open flame; Place the bottom of the container in a warm

pail of water if container warming is required.

• Never intentionally drop, puncture, or incinerate refrigerant containers.

• Keep refrigerant away from open flames: poisonous gas is produced if refrigerant burns.

• Refrigerant displaces oxygen, therefore be certain to work in well ventilated areas to prevent suffo-

cation.

• Never pressure test or leakage test HFC-134a (R-134a) service equipment and/or vehicle air condi-

tioning systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a)

have been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause

injury or property damage. Additional health and safety information may be obtained from refriger-

ant manufacturers.

Refrigerant Connection

INFOID:0000000005249889

A new type refrigerant connection has been introduced to all refrigerant lines except the following location.

• Expansion valve to evaporator

• Refrigerant pressure sensor to liquid tank

ABOUT ONE-TOUCH JOINT

Description

• One-touch joints are pipe joints which do not require tools during piping connection.

• Unlike conventional connection methods using union nuts and flanges, controlling tightening torque at con-

nection point is not necessary.

• Use a disconnector when removing a pipe joint.

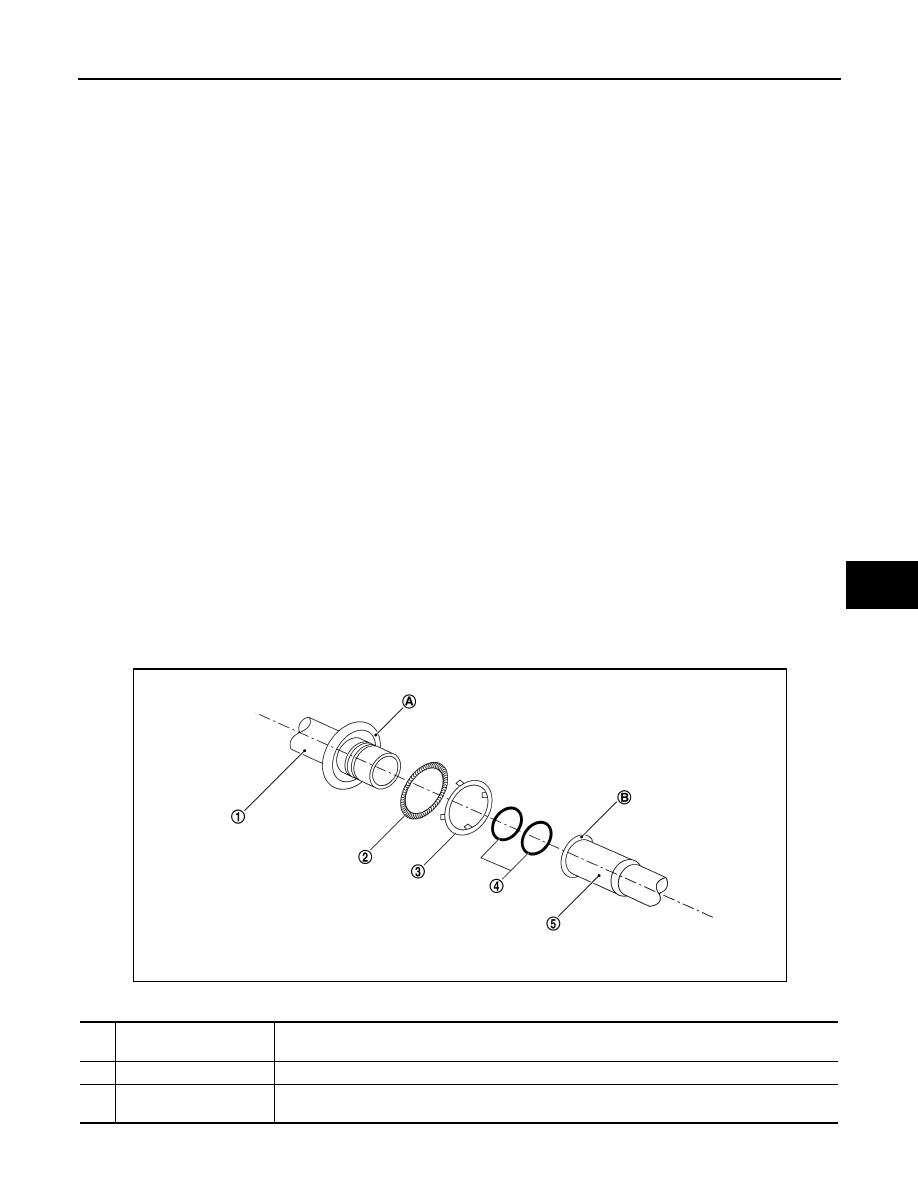

COMPONENT PARTS

FUNCTIONS OF COMPONENT PARTS

1

Pipe (Male-side)

• Retains O-rings.

• Retains garter spring in cage (A).

2

Garter spring

Anchors female-side piping.

3

Indicator ring

When connection is made properly, this is ejected from male-side piping. (This part is no longer nec-

essary after connection.)

RJIA4383J