SiteSentinel iTouch Tank Monitoring System. Installation Manual

SiteSentinel® iTouch™

Tank Monitoring System

Installation Manual

Table of Contents

1 Introduction

10

1.1

Warnings

10

1.1.1 Safety

10

1.1.2 Fire and Explosion Hazard

10

1.1.3 Dangerous Voltages

10

1.1.4 Compliance

10

1.1.5 Precision Leak Test

10

1.1.6 Initial Inspection

11

1.1.7 Connect Internal Battery

11

2 Specifications

12

2.1

SiteSentinel® iTouch™ Controller

12

2.2

Printer

13

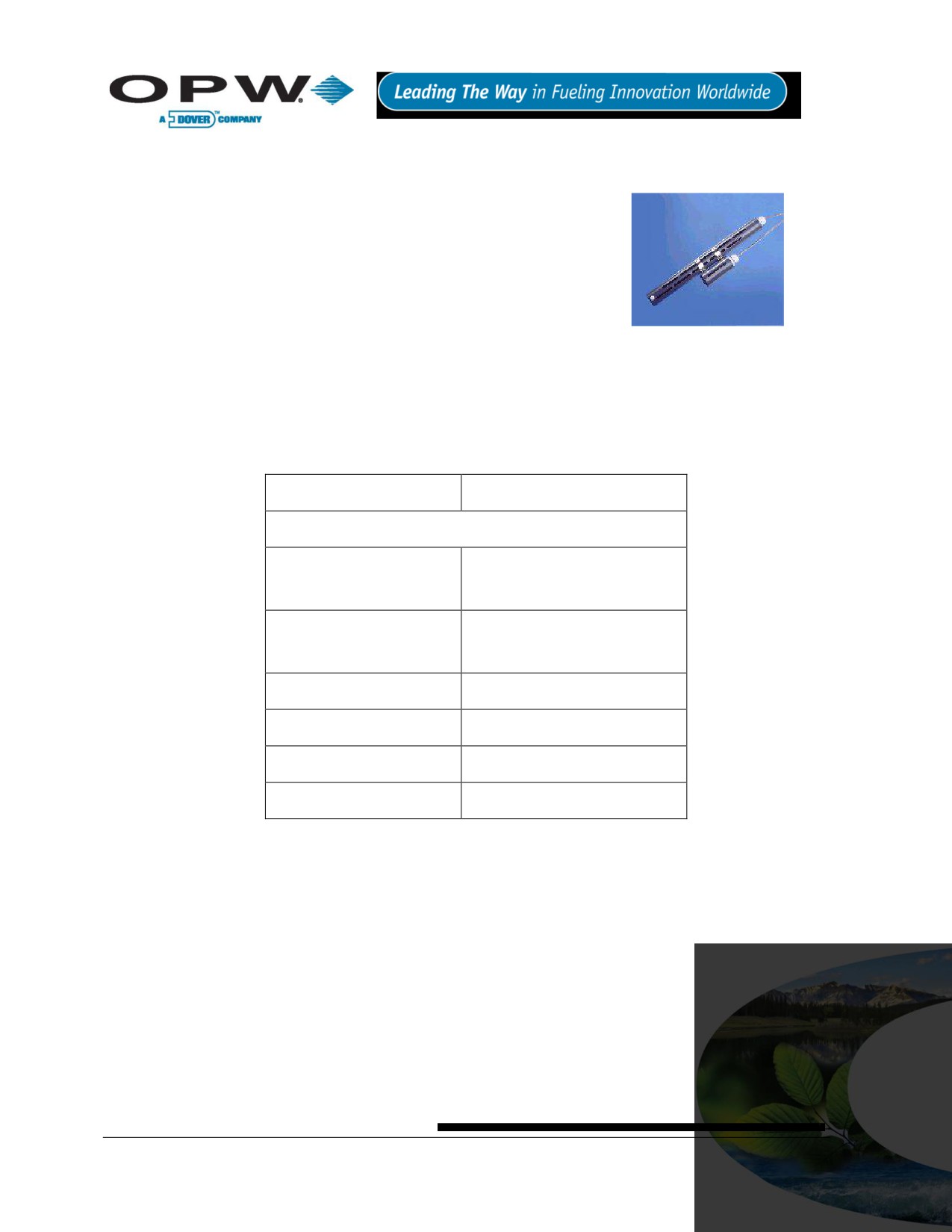

3 Magnetostrictive Probe (Model 924B)

14

3.1

About the Probe

14

3.2

Probe Specifications

15

3.3

Probe Lengths/Installation Scenarios

16

4 Controller Installation

17

4.1

Mounting the Controller

17

4.2

Mounting the Optional Printer Bracket

18

4.3

Installing the Controller Power Supply Conduit

19

4.4

Wiring the Controller Power Supply

20

4.4.1 Grounding the SiteSentinel® iTouch™ Tank Gauging System

21

4.4.2 SiteSentinel® iTouch™ Port Protection

21

5 Preparing for Probe and Sensor Installation

23

5.1

Probe and Sensor Wiring

23

5.1.1 Compliance

23

5.1.2 Wire Type

23

5.1.3 Probe Wiring

23

5.1.4 Sensor Wiring

23

5.1.5 Wire Length

23

5.1.6 Wire Splices

23

5.2

Conduit

24

6 Seal-Offs

25

6.1

Junction Boxes

25

7 Preparing Your Tanks for Probes

26

7.1

Underground Tank Manholes

26

7.2

Precision Leak Test

27

7.3

Probe Placement

27

8 Product Float and Water Float Offsets

28

8.1

Offset Procedure

28

8.1.1 Float Offset Example

28

8.2

Calculating Tank Tilt and Offset Factor

29

9 Probes

30

9.1

Probe Floats

30

9.1.1 Product Level vs. Water Level

30

9.1.2 Water Float Weight Specification

30

9.1.3 Installing the Float(s)

30

10 Product Density & Chemical Compatibility

32

10.1

Determining Water Float Product Group

33

Page 3 of 123

11 Part Numbers

34

12 Probes Wiring

35

13 Sensors

38

13.1

Before You Begin

38

13.2

30-3206 Interstitial Hydrocarbon Liquid/Water Sensor

38

13.2.1

About the 30-3206

38

13.2.2

Specifications

38

13.2.3

Installing the 30-3206

39

13.2.4

Connections

39

13.2.5

Typical Interstitial Hydrocarbon Liquid/Water Sensor Installation

40

13.2.6

SiteSentinel® iTouch™ Controller Setup for Interstitial (“IS”) Hydrocarbon Liquid/Water Sensor

40

13.2.7

1st IS Module Position - Hydrocarbon Liquid

40

13.2.8

2nd IS Module Position - Water

41

13.2.9

Testing and Decontaminating the Interstitial Hydrocarbon Liquid/Water Sensor

41

13.3

30-3207 Hydrocarbon Liquid Sensor

42

13.3.1

About the 30-3207-06, -10, -15

42

13.3.2

Specifications

42

13.3.3

Installing the 30-3207-06, -10, or -15

42

13.3.4

Connections

42

13.3.5

Typical Hydrocarbon Liquid Sensor Installation

43

13.3.6

SiteSentinel® iTouch™ Controller Setup for Hydrocarbon Liquid Sensor

43

13.3.7

Testing and Decontaminating the Hydrocarbon Liquid Sensor

43

13.4

30-3210-06, -10, -15 Hydrocarbon Liquid/Water Sensor

44

13.4.1

About the 30-3210-nn

44

13.4.2

Specifications

44

13.4.3

Installing the 30-3210-06, -15, -20

45

13.4.4

Connections

45

13.4.5

Typical Hydrocarbon Liquid/Water Sensor Installation

46

13.4.6

SiteSentinel® iTouch™ Controller Setup for Hydrocarbon Liquid/Water Sensor

46

13.4.7

Hydrocarbon Sensor Configuration

46

13.4.8

Water Sensor Configuration

46

13.4.9

Testing the Sensor

47

13.5

30-3219-12 Hydrocarbon Liquid Sump Sensor

48

13.5.1

About the 30-3219-12

48

13.5.2

Specifications

48

13.5.3

Installing the 30-3219-12

49

13.5.4

Connections

49

13.5.5

Typical Hydrocarbon Liquid Sump Sensor Installation

50

13.5.6

SiteSentinel® iTouch™ Controller Setup for Hydrocarbon Liquid Sump Sensor

50

13.5.7

Testing and Decontaminating the Hydrocarbon Liquid Sump Sensor

51

13.6

30-3221-1 Single-Level Sump Sensor

51

13.6.1

About the 30-3221-1

51

13.6.2

Specifications

51

13.6.3

Installing the 30-3221-1

52

13.6.4

Connections

52

13.6.5

Typical Single-Level Sump Sensor Installation

53

13.6.6

SiteSentinel® iTouch™ Controller Setup for Single-Level Sump Sensor

53

13.6.7

Testing the Single-Level Sump Sensor Float

53

13.7

30-3221-2 Dual-Level Reservoir Sensor

54

13.7.1

About 30-3221-2

54

13.7.2

Specifications

54

13.7.3

Installing the 30-3221-2

55

13.7.4

Connections

55

Page 4 of 123

13.7.5

Typical Dual-Level Reservoir Sensor Installation

56

13.7.6

SiteSentinel® iTouch™ Controller Setup for Dual-Level Reservoir Sensor

56

13.7.7

Testing the Dual-Level Reservoir Sensor Float

57

13.8

30-3221-1A, -1B Interstitial Level Sensors

58

13.8.1

About the 30-3221-1A, 1B

58

13.8.2

Specifications

58

13.8.3

Installing the 30-3221-1A, -1B

59

13.8.4

Connections

59

13.8.5

Typical Interstitial Level Sensor Installation

60

13.8.6

SiteSentinel® iTouch™ Controller Setup for Interstitial Level Sensor

60

13.8.7

Testing the Float Sensor

61

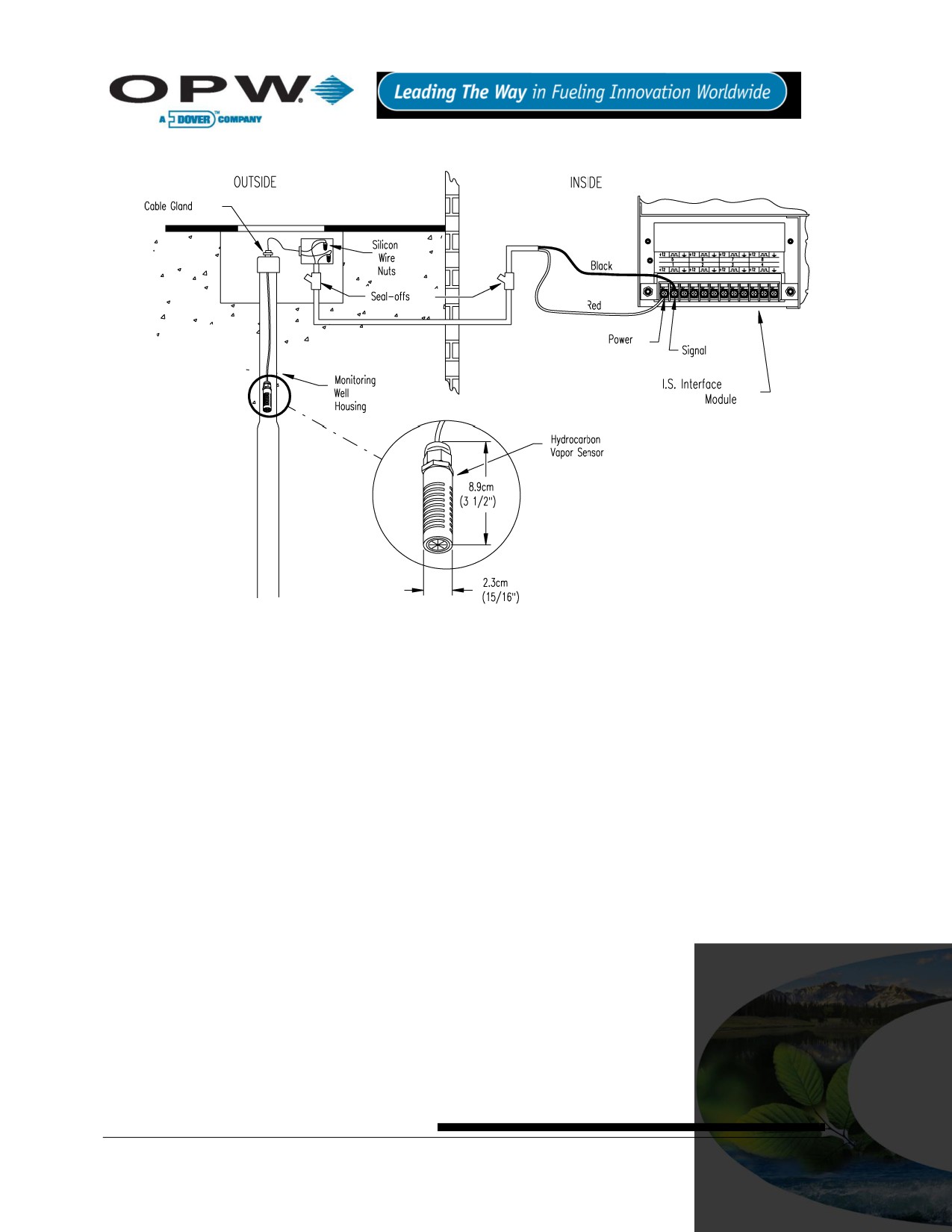

13.9

30-3222 Hydrocarbon Vapor Sensor

62

13.9.1

About Part #30-3222

62

13.9.2

Specifications

62

13.9.3

Installing the 30-3222

63

13.9.4

Connections

63

13.9.5

Typical Hydrocarbon Vapor Sensor Installation

64

13.9.6

SiteSentinel® iTouch™ Controller Setup for Hydrocarbon Vapor Sensor

64

13.9.7

Testing and Decontaminating the Hydrocarbon Vapor Sensor

65

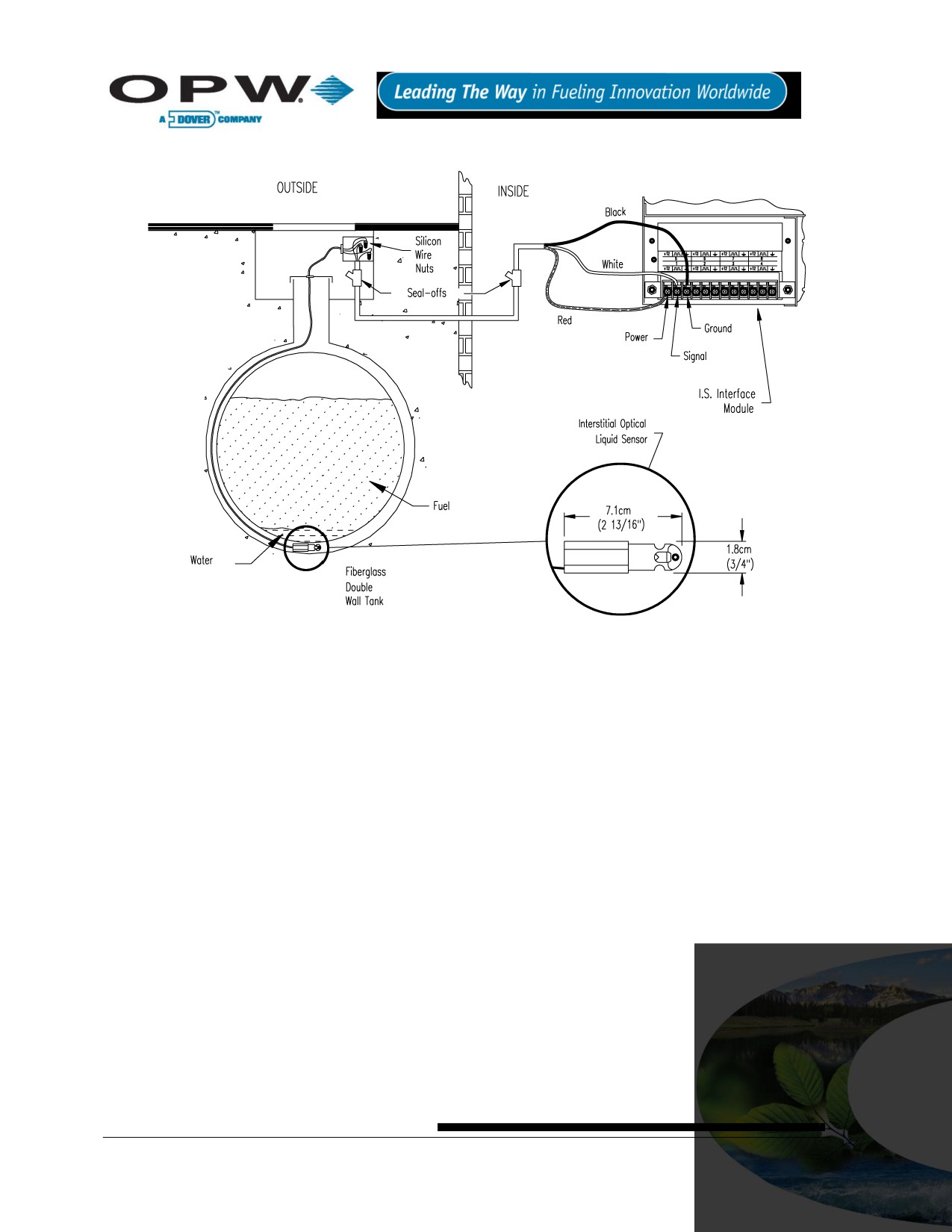

13.10

30-3223 Interstitial Optical Liquid Sensor

66

13.10.1 About the 30-3223

66

13.10.2 Specifications

66

13.10.3 Installing the 30-3223

66

13.10.4 Connections

66

13.10.5 Typical Interstitial Optical Liquid Sensor Installation

67

13.10.6 Controller Setup for Interstitial Optical Liquid Sensor

67

13.10.7 Testing the Interstitial Optical Liquid Sensor

67

13.11

30-3224 Combo Single Level/Hydrocarbon Liquid Sump Sensor

68

13.11.1 About the 30-3224

68

13.11.2 Specifications

68

13.11.3 Installing the 30-3224

69

13.11.4 Connections

69

13.11.5 Typical Combo Single-Level/Hydrocarbon Liquid Sump Sensor Installation

70

13.11.6 Controller Setup for Combo Single-Level/Hydrocarbon Sump Sensor

70

13.11.7 Testing the Float Sensor Portion of the Combo Sensor

71

13.11.8 Testing and Decontaminating the Hydrocarbon Sensor Portion of the Combo Sensor

71

13.12

30-3225 Combo Dual Level/Hydrocarbon Liquid Sump Sensor

72

13.12.1 About the 30-3225

72

13.12.2 Specifications

72

13.12.3 Installing the 30-3225

73

13.12.4 Combo Sensor Connections

73

13.12.5 Typical Dual-Level Hydrocarbon Liquid Sump Sensor Installation

74

13.12.6 Controller Setup for 30-3225

74

13.12.7 Testing the Float Sensor Portion of the Combo Sensor

75

13.12.8 Testing and Decontaminating the Hydrocarbon Portion of the Combo Sensor

75

13.12.9 Testing the Water Sensor Portion of the Combo Sensor

75

14 External Device Connection

76

15 RJ-45 Communication Ports

77

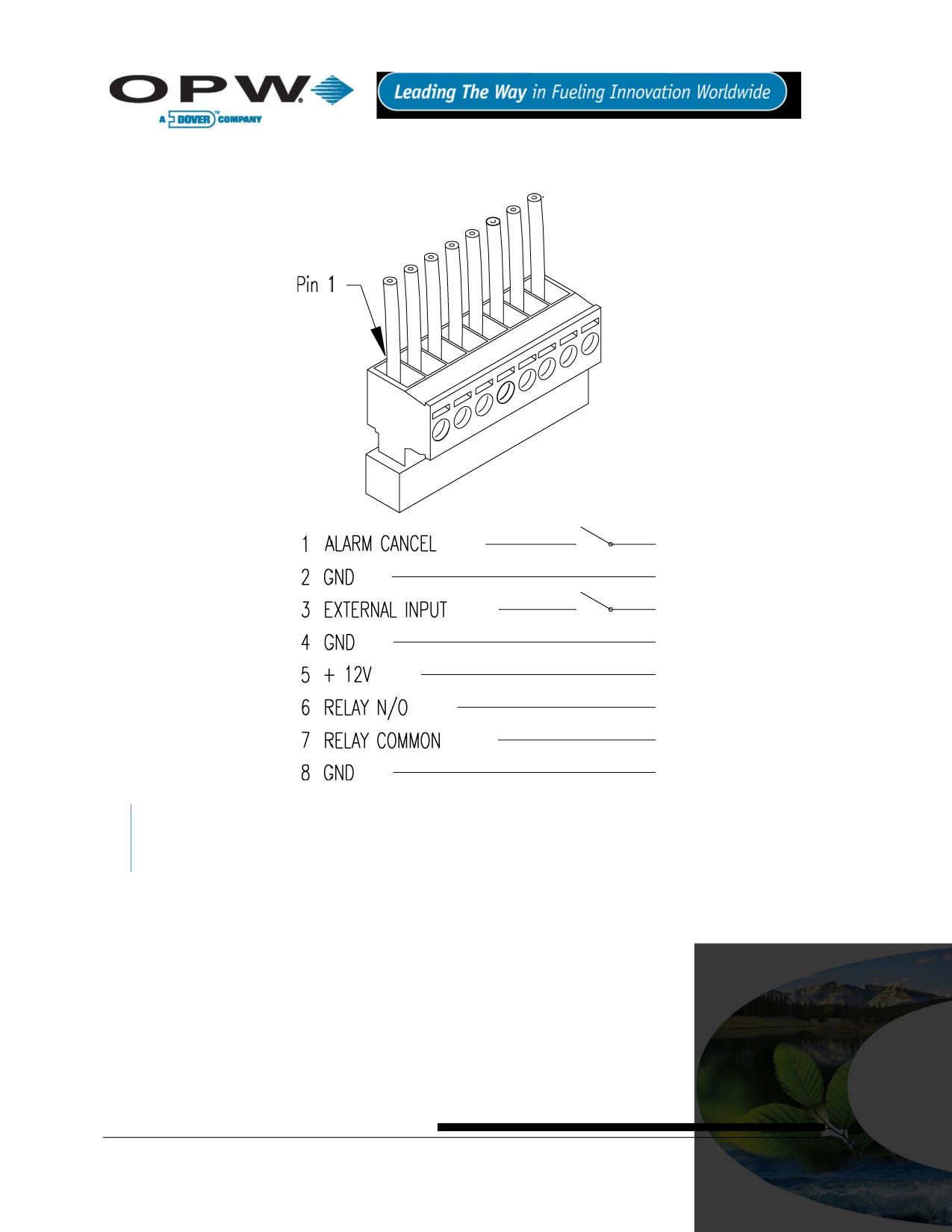

16 Terminal Block Detail

78

17 Printer Option

79

17.1

Modem Connections

80

18 CAP Connection for SiteConnect™ Software

81

18.1

POS Interface Option

81

Page 5 of 123

18.2

Built-in TCP/IP Connections

81

19 Appendix A - LCD Screen Icons

82

19.1

Sensor, Probe and Controller Status Icons

82

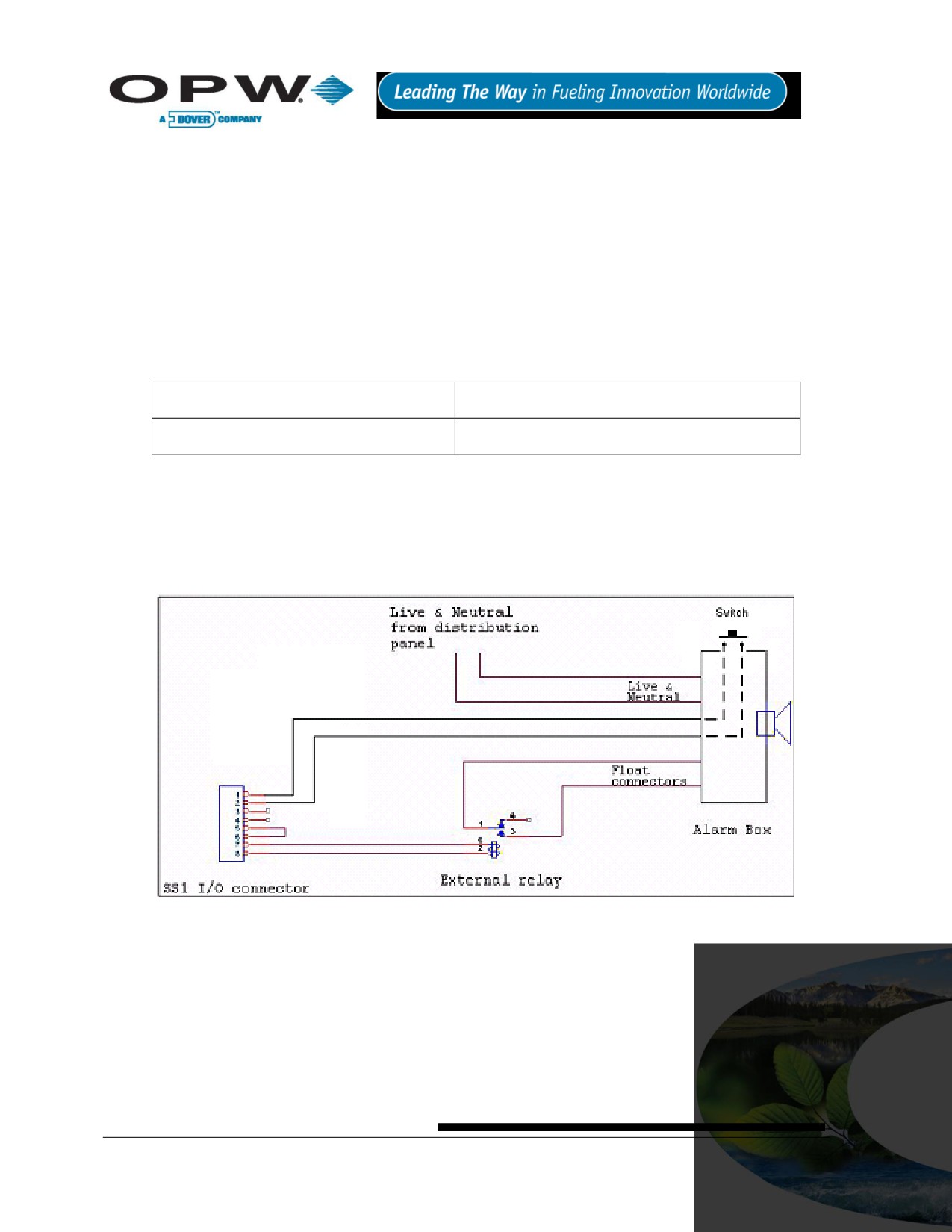

20 Appendix B - Alarm Kit Option

83

20.1

Alarm Kit Part Numbers

83

20.2

Installation

83

20.3

Alarm Kit Connections

84

21 Appendix C - POS Interface

85

21.1

SiteSentinel® iTouch™ POS Port

85

21.2

Prepare and Attach the Cable

85

22 Appendix D - Upgrading SiteSentinel® iTouch™ Software Via SiteConnect™

86

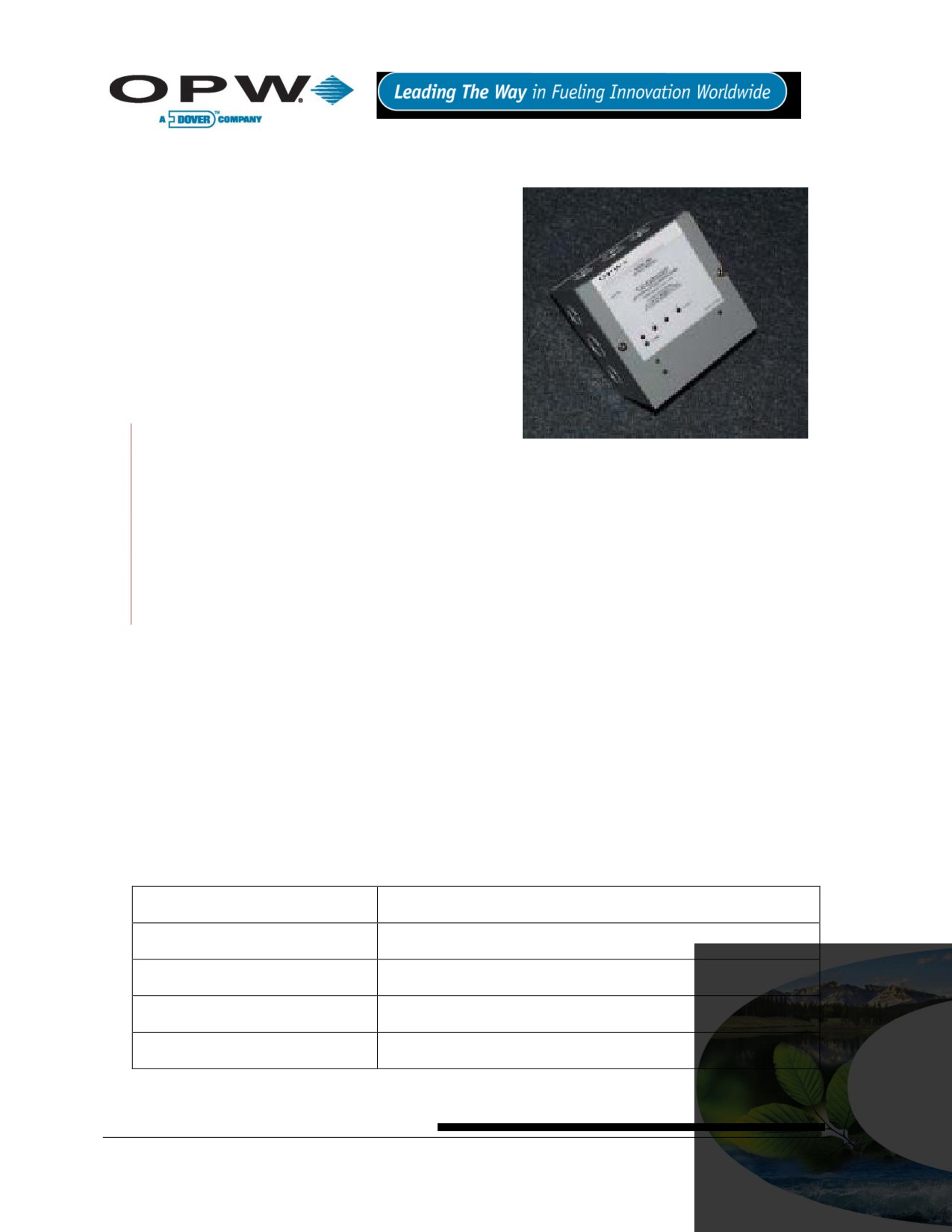

23 Appendix E - OM4 Output Module Option

88

23.1

Codes

88

23.2

Hazardous Area Definition

88

23.3

OM4 Output Module Specifications

88

23.4

Installing the OM4

89

24 Appendix F - LPG Probe Option

91

24.1

About the LPG Probe

91

24.1.1

30.1510 Probe Kit (Figure 41) Contents

91

24.2

30-1511 Probe Kit (Figure 24-2) Contents

92

24.2.1

Head Cover Kit (Figure 24-3) Contents

92

24.3

Installing the LPG Probe

93

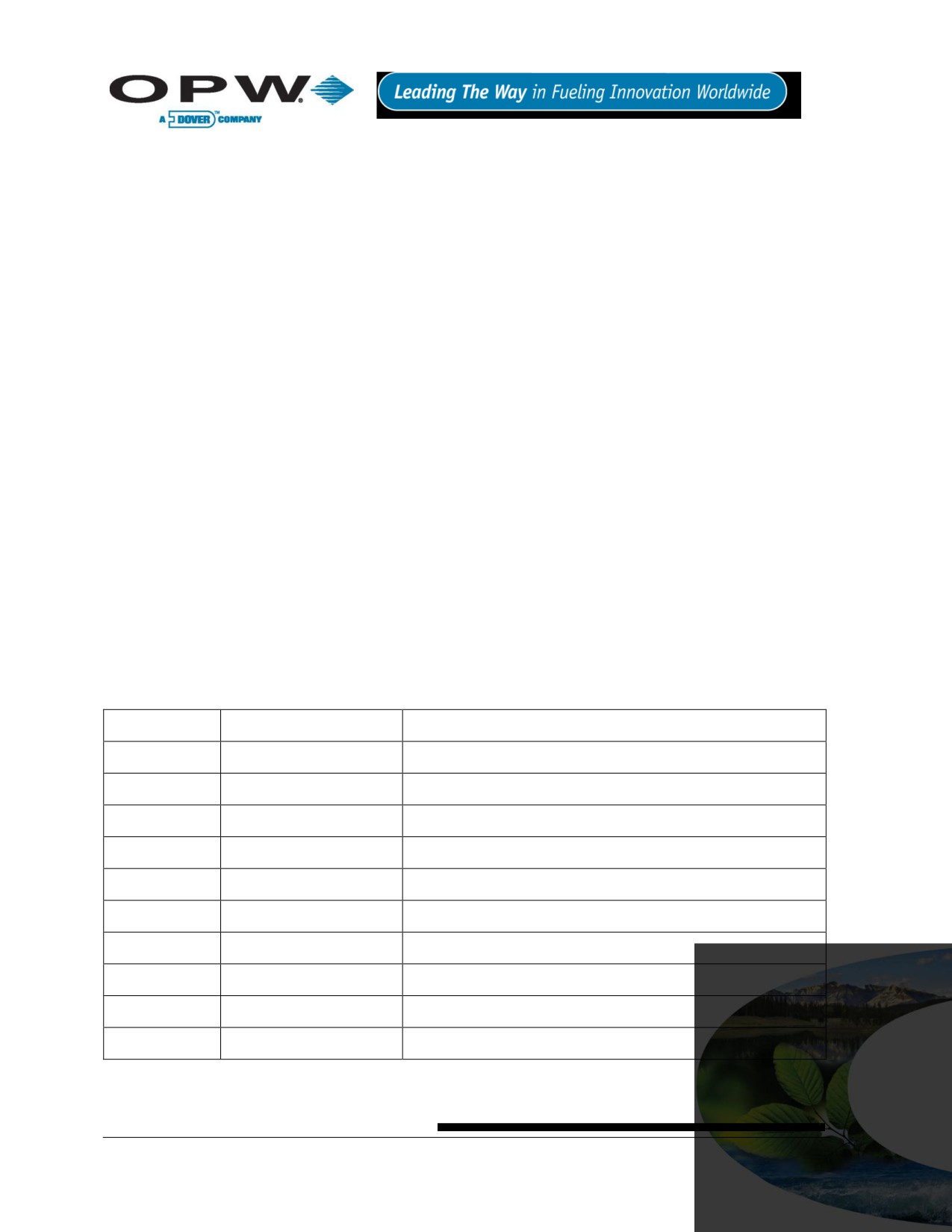

25 Appendix G - Probe Comparison

95

25.1

Model 924 and 924B Magnetostrictive Probe Probe Comparison

95

25.2

Ordering the New Probe

95

25.3

Probe Installation

96

26 Appendix H - Hardware for SiteSentinel® iTouch™ Controller Main Board

97

26.1

Hardware Overview

97

26.2

Hardware Detail

99

26.2.1

Communication Ports

99

26.3

Status Indicators

100

26.4

Dip Switch

100

27 Appendix I - EPA Certifications

101

Index

123

List of Figures

Figure 2-1 SiteSentinel® iTouch™ Controller

12

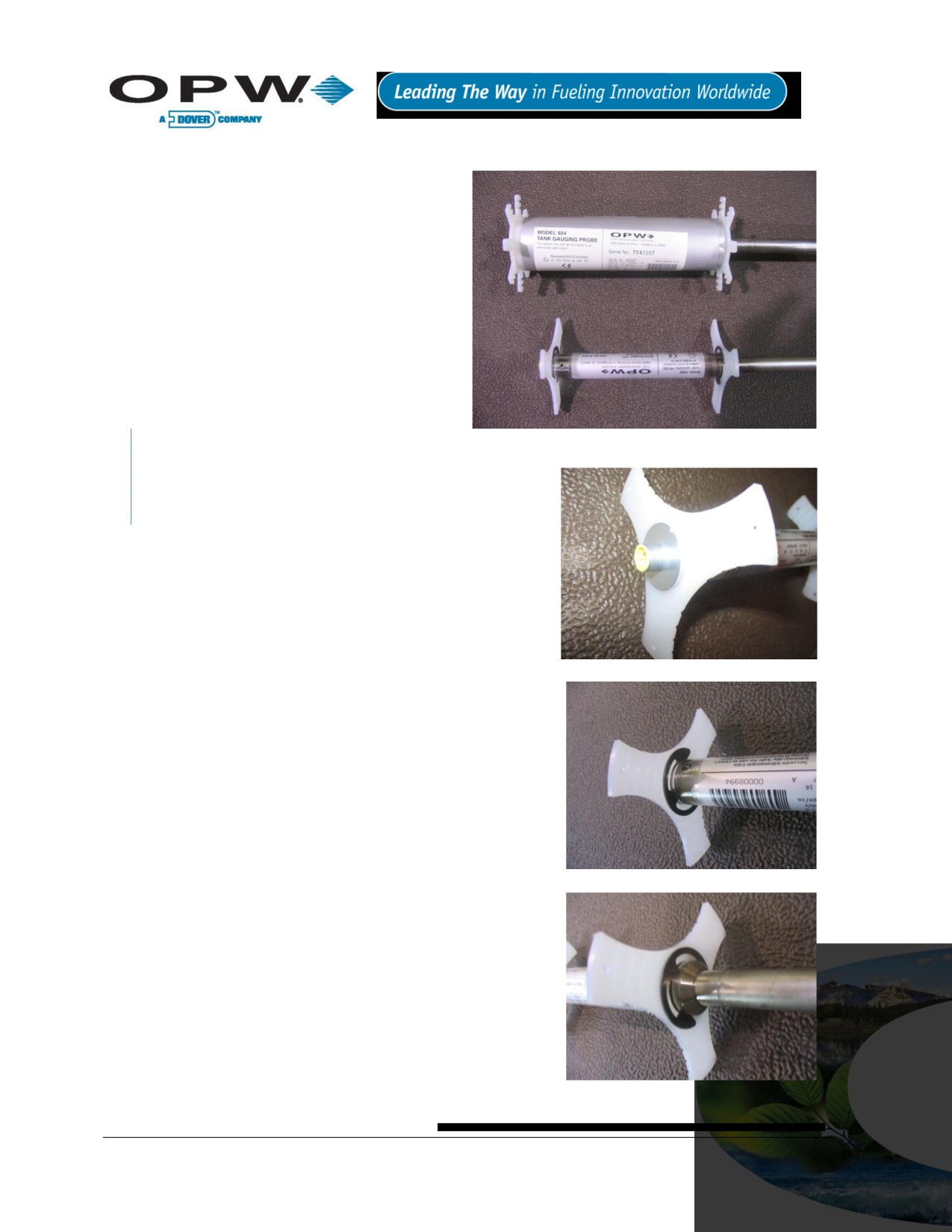

Figure 3-1 924B Probe

14

Figure 3-2 Probe in Manhole-Equipped Tank

16

Figure 3-3 Probe in Tank With No Manhole

16

Figure 4-1 Mounting Footprint

17

Figure 4-2 Printer Bracket Mounting Dimension

18

Figure 4-3 Controller Conduit Knockouts

19

Figure 4-4 SiteSentinel® iTouch™ Ground Lugs

21

Figure 4-5 SiteSentinel® iTouch™ External Surge Protector (75-0104)

21

Figure 4-6 SiteSentinel® iTouch™ External Surge Protector I/O Port Connection (75-0104)

22

Figure 6-1 Creating a Seal-Off

25

Figure 7-1 Underground Tank Manholes

26

Figure 7-2 Probe Placement in Tank

27

Figure 8-1 Calculating Tank Tilt

29

Figure 9-1 Probe Component Locator

31

Figure 10-1 Determining Water Level Indicator Type

33

Figure 12-1 Probe Connections - TWO Conductor Shielded Cable

36

Figure 13-1 Interstitial Hydrocarbon Liquid/Water Sensor

38

Figure 13-2 Interstitial (IS) Hydrocarbon Liquid/Water Sensor Installation

40

Figure 13-3 Hydrocarbon Liquid Sensor

42

Figure 13-4 Hydrocarbon Liquid Sensor Installation

43

Figure 13-5 Hydrocarbon Liquid/Water Sensor

44

Figure 13-6 Hydrocarbon Liquid & Water Sensor Installation

46

Figure 13-7 Hydrocarbon Liquid Sump Sensor

48

Figure 13-8 Hydrocarbon Liquid Sump Sensor Installation

50

Figure 13-9 Single-Level Sump Sensor

51

Figure 13-10 Single-Level Sump Sensor Installation

53

Figure 13-11 Dual-Level Reservoir Sensor

54

Figure 13-12 Dual-Level Sump Sensor Installation

56

Figure 13-13 Part # 30-3221-1B

58

Figure 13-14 Part # 30-3221-1A

58

Figure 13-15 Interstitial Level Sensor Installation

60

Figure 13-16 Hydrocarbon Vapor Sensor

62

Figure 13-17 Hydrocarbon Vapor Sensor Installation

64

Figure 13-18 Interstitial Optical Liquid Sensor

66

Figure 13-19 Interstitial Optical Liquid Sensor Installation

67

Figure 13-20 Combo Single Level/Hydrocarbon liquid Sump Sensor

68

Figure 13-21 Combo Single-Level & Hydrocarbon Liquid Sensor Installation

70

Figure 13-22 Combo Dual Level/Hydrocarbon Liquid Sump Sensor

72

Figure 13-23 Combo Dual-Level & Hydrocarbon Liquid Sensor Installation

74

Figure 14-1 Connecting External Devices to the Controller

76

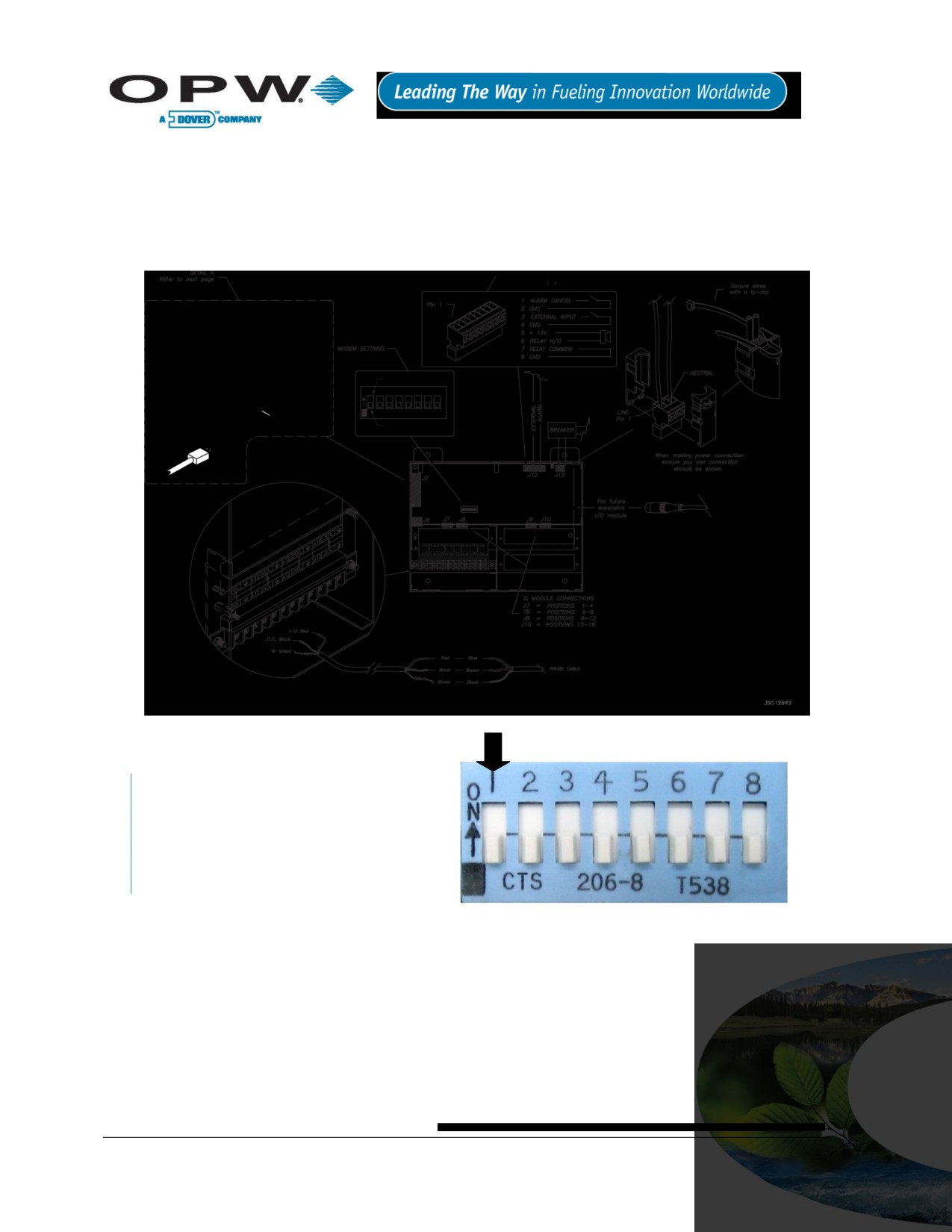

Figure 14-2 Dip Switch for Modem Settings

76

Figure 15-1 SiteSentinel® iTouch™ RJ-45 Communication Ports

77

Figure 16-1 SiteSentinel iTouch Terminal Block Connections

78

Figure 20-1 External Alarm Wiring

83

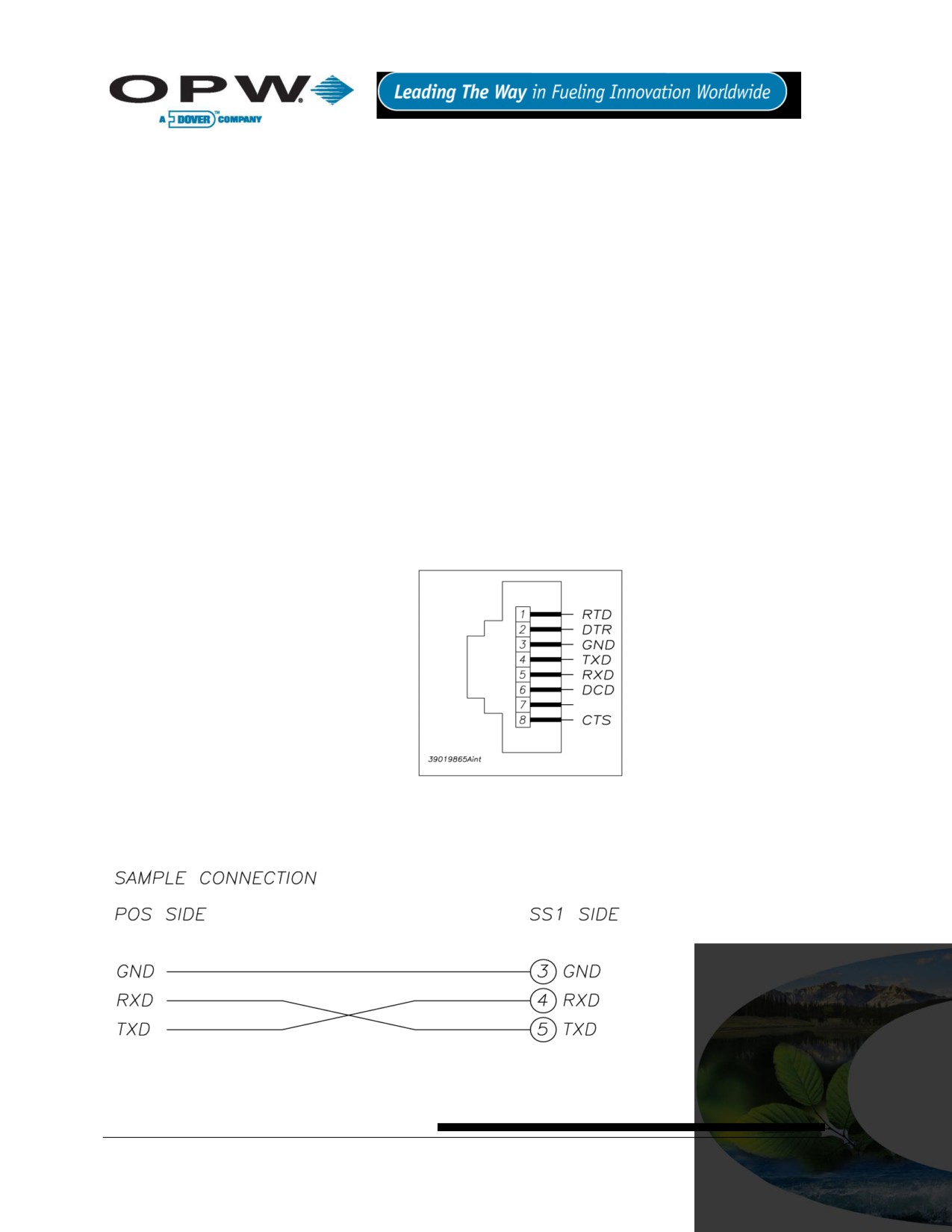

Figure 21-1 Pinout for POS-to-SiteSentinel® iTouch™ Cable

85

Figure 23-1 SS1-to-OM4 Connection

89

Figure 23-2 DIN Connector Access

89

Figure 23-3 OM4 Output Module Wiring

90

Figure 23-4 Address Jumper for #2 OM

90

Figure 24-1 What's Supplied in the 30-1510 Kit

91

Figure 24-2 What's Supplied in the 20-1511 Kit

92

Figure 24-3 30-1512 Head Cover Kit Contents

92

Figure 24-4 Probe Assembly and Installation Overview

93

Figure 25-1 924 vs. 924B Probe Head

96

Figure 25-2 Top Stabilizer

96

Figure 25-3 Top Clip

96

Figure 25-4 Lower Stabilizer and Clip

96

Figure 26-1 SSI Board (0322)

97

Figure 26-2 Communication Ports

99

Figure 26-3 Power Supply

99

Figure 26-4 Status Indicators

100

Figure 26-5 DIP Switch

100

List of Tables

Table 5-1 Probe Quantity vs. Conduit Capacity

24

Table 10-1 Product Compatibility

32

Table 10-2 Product Compatibility (continued)

32

Table 11-1 Part Numbers

34

Table 12-1 I.S. Interface Module Connections to Belden TWO-CONDUCTOR Cable with Shield

35

Table 12-2 I.S. Probe Connections to Belden THREE-CONDUCTOR Cable

35

Table 13-1 Interstitial Hydrocarbon Liquid/Water Sensor Wiring

39

Table 13-2 Hydrocarbon Liquid Sensor Wiring

42

Table 13-3 Hydrocarbon Liquid/Water Sensor Wiring

45

Table 13-4 Hydrocarbon Liquid Sump Sensor Wiring

49

Table 13-5 Single-Level Sump Sensor Wiring

52

Table 13-6 Dual-Level Reservoir Sensor Connections

55

Table 13-7 Interstitial Level Sensor Wiring

59

Table 13-8 Hydrocarbon Vapor Sensor Wiring

63

Table 13-9 Interstitial Optical Liquid Sensor Wiring

66

Table 13-10 Combo Single-Level/Hydrocarbon Sensor Wiring

69

Table 13-11 Combo Dual-Level/Hydrocarbon Liquid Sump Sensor

73

Table 17-1 Printer DIP Switch 1 Settings

79

Table 17-2 Printer DIP Switch 2 Settings

79

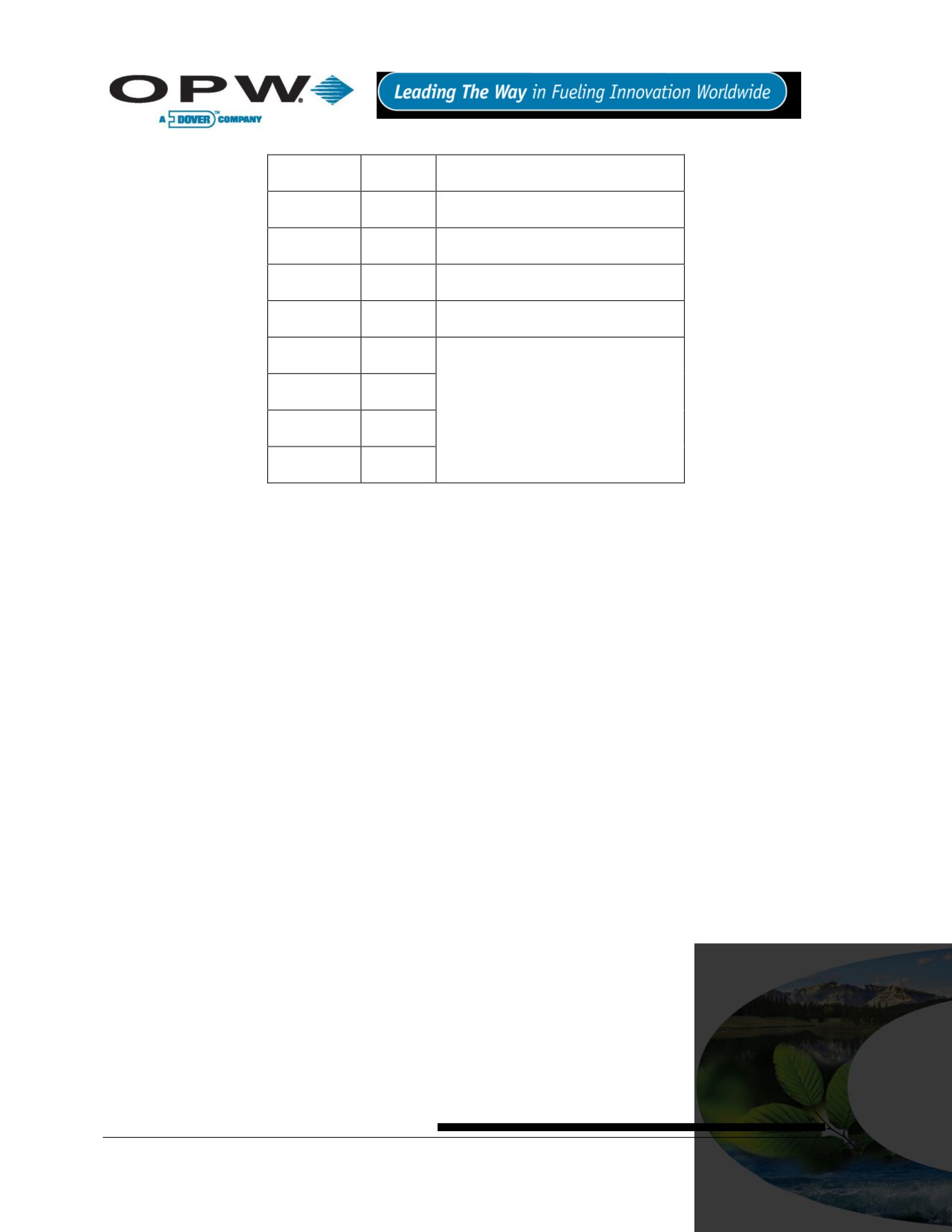

Table 17-3 Printer DIP Switch 3 Settings

80

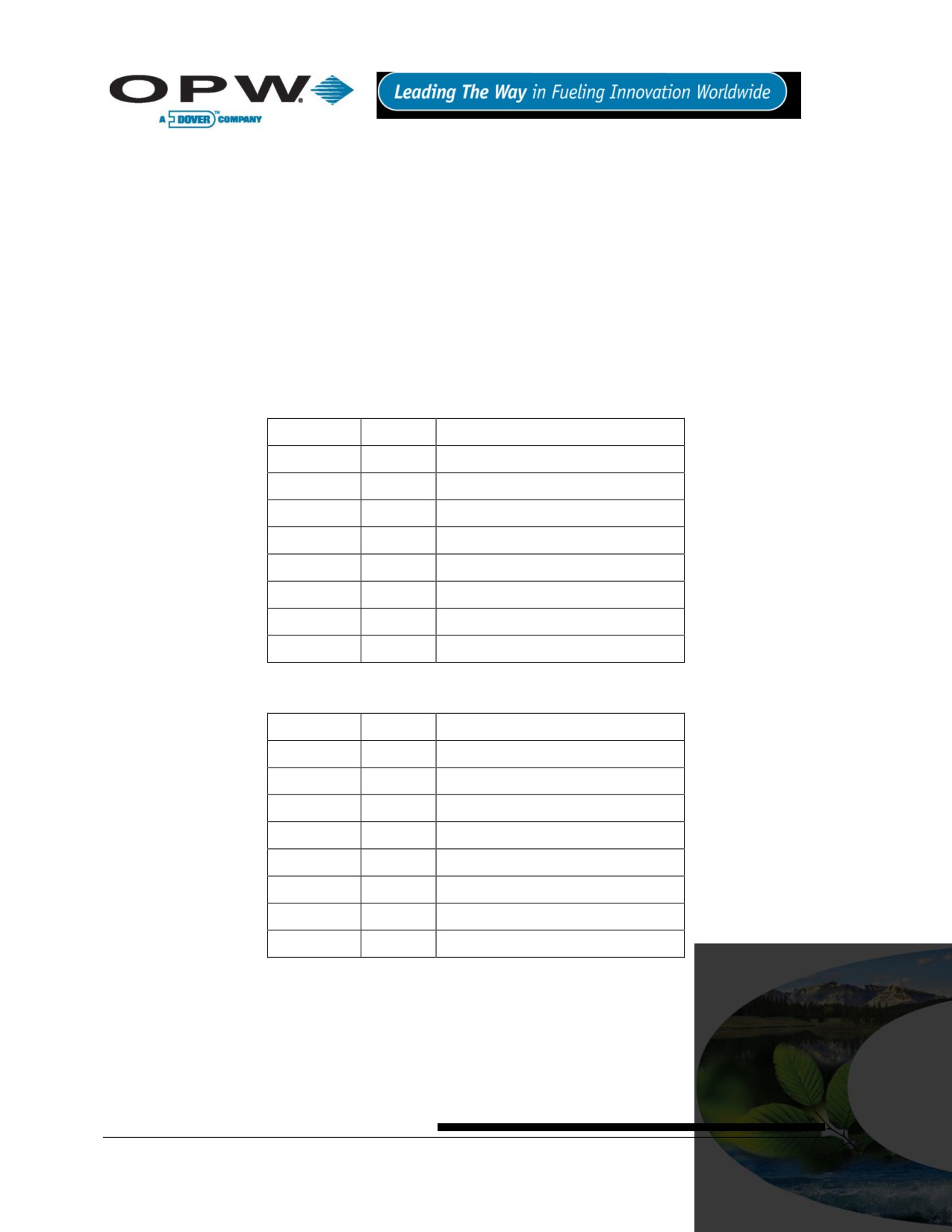

Table 20-1 External Alarm Relay Specifications (NOT Supplied)

83

Table 20-2 Alarm Kit Connections

84

Table 23-1 Wiring Connections for Alarm Kit

88

Table 25-1 924 Probe Conversion Chart

95

Table 26-1 Comparison chart of the current (0320) and new (0322) SiteSentinel iTouch main board

98

Page 9 of 123

1 Introduction

This manual describes the installation procedures for the SiteSentinel® iTouch™ Integrated Monitoring System.

Included in this manual are installation instructions for the Controller, probes and sensors.

1.1 Warnings

1.1.1 Safety

When working in an environment containing fuel and fuel vapors, there is ALWAYS a

risk of fire and explosion.

TO AVOID SEVERE INJURY OR DEATH, KEEP ALL POSSIBLE IGNITION

SOURCES AWAY FROM HAZARDOUS AREAS.

1.1.2 Fire and Explosion Hazard

Disconnect power before installing. DO NOT install this equipment in a volatile,

combustible or explosive atmosphere (the “hazardous area” defined in the National

Electrical Code).

1.1.3 Dangerous Voltages

Certain components have DANGEROUS voltages even with the power cord

disconnected.

Many of the procedures described in the following pages must be followed for each

tank that is to be included in the system. Please read the directions carefully before

proceeding.

Improper installation may endanger installers and users of this equipment!

Read these instructions CAREFULLY.

Installers must know the requirements of intrinsically safe devices, and must

strictly obey instructions in this manual to perform a safe installation.

1.1.4 Compliance

Installation must comply with the National Electrical Code (NFPA No. 70) and the Autom

Service Station Code (NFPA No. 30A).

Follow all of your local or regional codes, as well.

A fuel tank is a hazardous area as defined in the NEC. Do not mount any part of the system, or any

external devices (other than probes or sensors) within or above the hazardous area.

1.1.5 Precision Leak Test

A precision leak test should be performed on each tank - especially older ones - before installing the

SiteSentinel® iTouch™. This test makes sure that leak data generated by the system is accurate and reliable. A

pressurized precision leak test can be done on a tank after the probe has been installed, but DO NOT let the

pressure exceed 20 psi.

Page 10 of 123

1.1.6 Initial Inspection

The packing list contains details about your system. It is packed in the box with this manual. Store this sheet in

a secure location. Be sure to check the packaging carefully for any damage that might have occurred during

shipping.

1.1.7 Connect Internal Battery

For shipping, the internal battery in the Controller is disconnected. To activate the internal battery, remove the

yellow strips.

Page 11 of 123

2 Specifications

“I.S.” (Intrinsically Safe) Interface Module refers to the sealed “terminal strip” inside the Controller. “I.S.

Interface Module Position” refers to one (1) set of three (3) screw terminals on this terminal strip (for

power, signal and ground connections). Each I.S. Interface Module contains four “positions.”

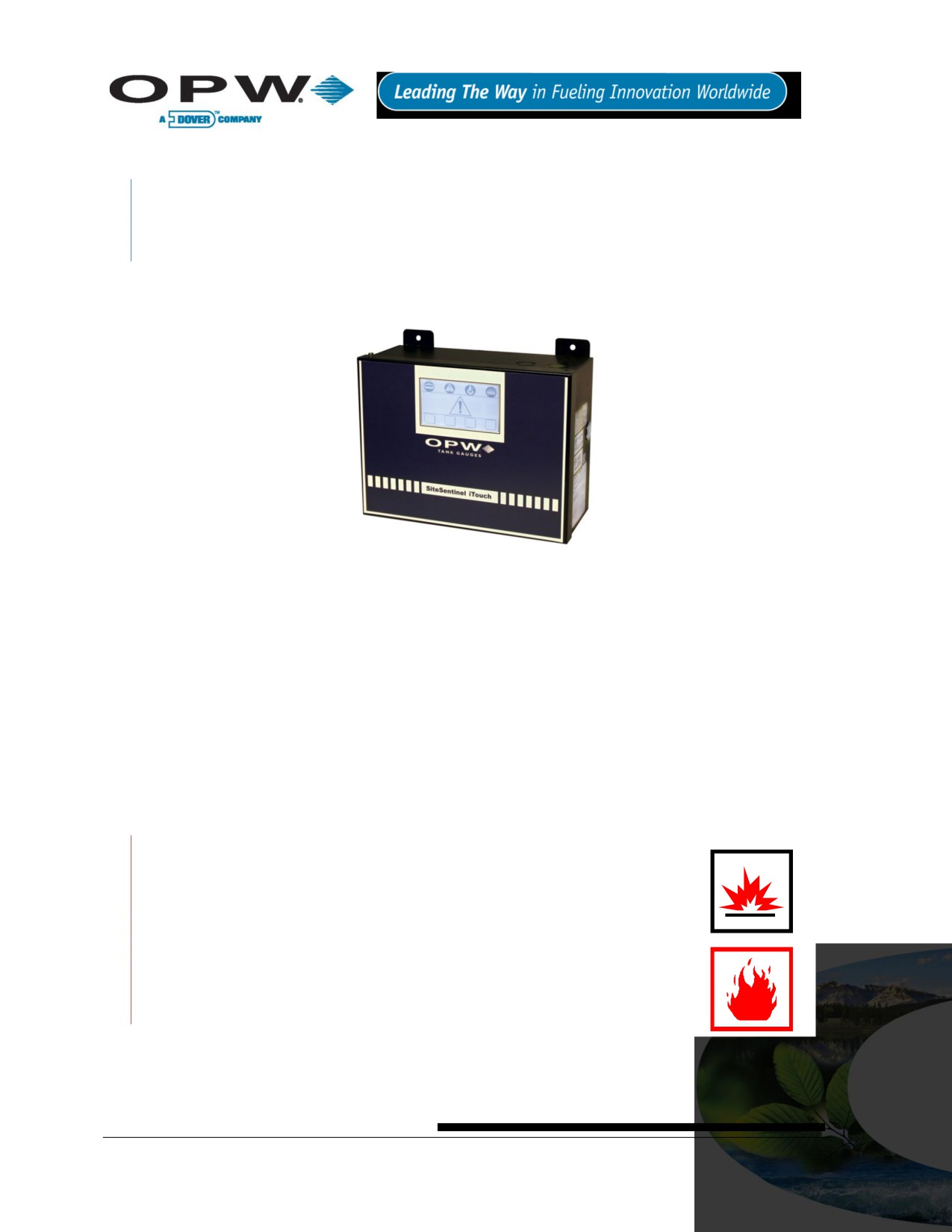

2.1 SiteSentinel® iTouch™ Controller

Figure 2-1 SiteSentinel® iTouch™ Controller

Physical Dimensions:

Height: 23.5 cm (9.25 in)

Width: 31.1 cm (12.25 in)

Depth: 13.3 cm (5.25 in)

Power Input:

100-250 VAC, 50/60 HZ, 1.0A

Operating Temperature Range:

0°C - 40°C (32°F - 104°F)

Remote Alarm Output:

Contact Rated at 30 VAC/DC 2A

Probe and Sensor Capacity:

16 probes and/or sensors

I.S. Interface Module:

14.5 VDC, 220 mA, 6.4 uF, 6 m

Optional Output Module OM4:

See Appendix E - OM4 Output

Option on page 88.

MOUNT THE CONTROLLER AND PRINTER OUTISDE THE HAZARDOUS AREA!

Substituting components will impair intrinsic safety.

For connection to intrinsically safe devices used in EEX ia IIA T4

(IEC/CENELEC) and Class 1, Division 1, Group D (North America) hazardous

locations.

For use ONLY with equipment specified in these installation instructions.

Document Nu

4

3

2.2 Printer

A thermal printer, the Seiko Model DPU-414, is available for reports and other printouts. See Figure 4-2 on

page18 for mounting instructions.

Physical Dimensions:

Height: 17.8 cm (7 in)

Width: 17.8 cm (7 in)

Depth (7.6 cm (3 in)

Power Input:

Provided by Controller

Operating Temperature Range:

0C° - 40°C (32F° - 104°F)

Page 13 of 123

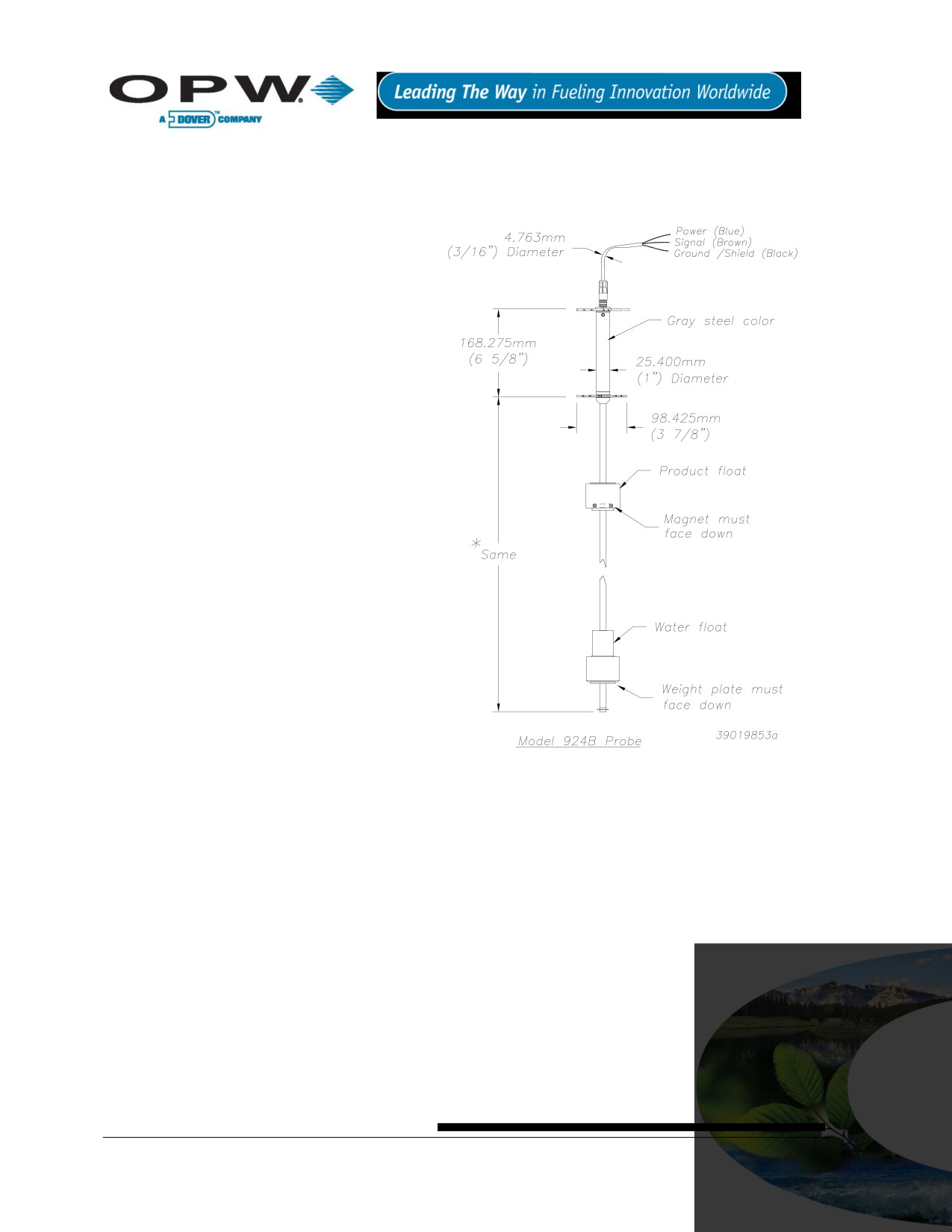

3 Magnetostrictive Probe (Model 924B)

3.1 About the Probe

The 924B probe uses magnetostrictive principles

to derive product and water levels, and product

temperatures. These probes are primarily used

in underground storage tanks for both inventory

and leak detection.

Two floats can be fitted to the probe shaft: The

upper (product) float sits on top of the product,

and the lower (water float) sits on the

product/water boundary at the bottom of the

tank.

Five temperature sensors reside in the probe

shaft for measuring product temperature. They

are located at positions of approximately 10%,

20%, 40%, 60% and 80% of the tank volume

(based upon a cylindrical tank). The sensors

compensate for the expansion and contraction of

the product with temperature and thus produce

net corrected product volume.

Figure 3-1 924B Probe

Page 14 of 123

3.2 Probe Specifications

Operating Temp. Range:

-40°C - 60°C (-40°F - 140°F)

Head Dimensions:

With connector, 21.5 cm x 2.54 cm (8.5 in x 1

in)

Cable:

1.83 m (6 ft) of gas & oil-resistant cable

Sensor Power:

Must be provided by OPW Fuel Management

Systems’ I.S. Interface Module

Certifications:

North America: Class I, Division 1, Group D

Outside North America:

Ex ia IIA T4 Ga

DEMKO 11 ATEX 1012670X

IECEx UL 11.0012X

Level Resolution:

0.0127 mm (0.0005 in)

Temp. Sensor Resolution:

Less than +/- 0.3°C or 0.5°F

Special Conditions for safe use:

On devices supplied with 4-inch floats: to avoid build-up of static charge, do not rub with a dry cloth or clean in

any manner that would result in a charge build-up. Discharge outside of hazardous area before putting into

service.

These devices have not been evaluated for use across a boundary wall.

The upper housing cover in the top of the enclosure is aluminum. Care must be taken to avoid ignition hazards

due to impact or friction.

A probe for LPG tanks is also available. See Appendix F - LPG Probe Option on page 91.

Page 15 of 123

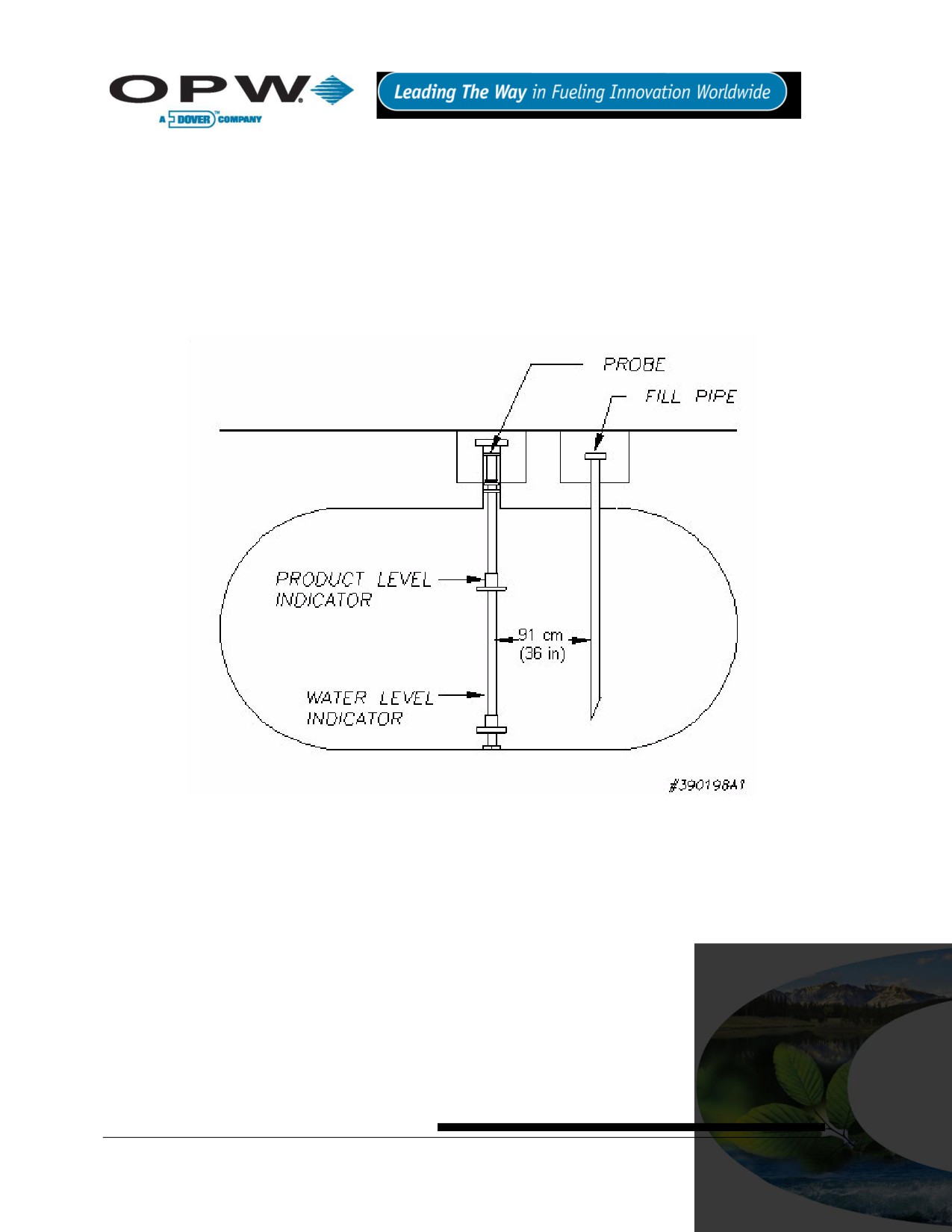

3.3 Probe Lengths/Installation Scenarios

Figure 3-2 Probe in Manhole-Equipped Tank

Figure 3-3 Probe in Tank With No Manhole

Page 16 of 123

4 Controller Installation

Choose a mounting location for the controller and printer. Choose an indoor mounting

location where it will be protected against moisture and extreme temperature and

humidity conditions.

Wall mount the controller at eye level close to a circuit breaker. Leave room above

and below controller for power, probe, sensor, remote alarm and other conduits that

must be connected to the controller.

If purchased, also leave room for the optional printer that normally mounts to the left of

the controller.

Do not mount the controller or external printer within or above the hazardous

area.

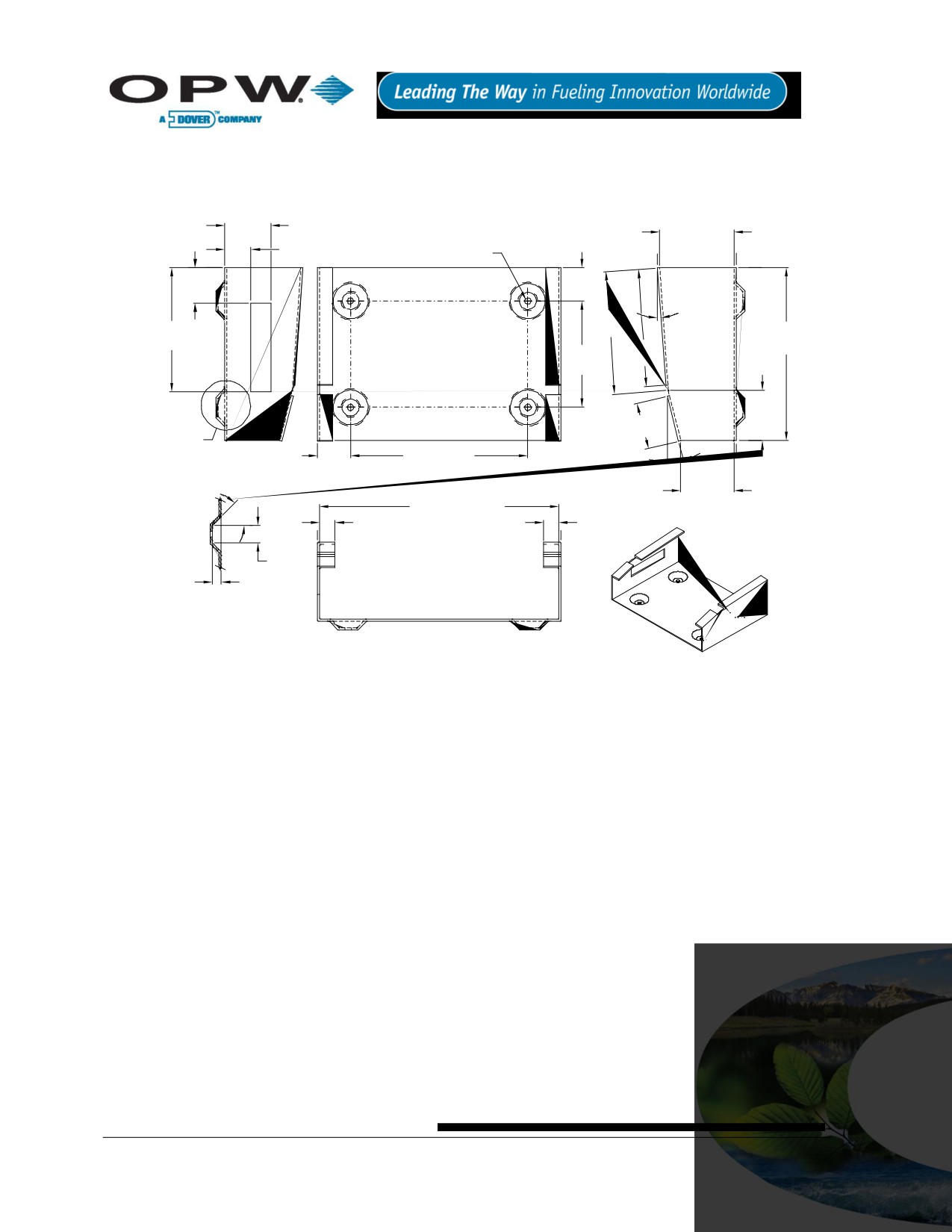

4.1 Mounting the Controller

Mount the controller to the wall using the dimensions shown in Figure 4-1 below. The four

0.80 cm (0.315 in) diameter. Use as large a fastener as possible.

Do not drill holes in the SiteSentinel® iTouch™ cabinet.

3.5 cm

24.1 cm (9 1/2")

(1 3/8")

22.2 cm

(8 3/4")

23.5 cm

(9 1/4")

Intrinsically Safe

Intrinsically Safe

Interface Module

Interface Module

Intrinsically Safe

Intrinsically Safe

Interface Module

Interface Module

31.1 cm (12 1/4")

FRONT VIEW

with door attached

Figure 4-1 Mounting Footprint

Page 17 of 123

4.2 Mounting the Optional Printer Bracket

Mount the printer bracket to the wall using Figure 4-2, below. Holes are 0.56 cm (0.22 in). Use as large a

fastener as possible, but ensure that the fastener does not protrude past the recess in the bracket.

33.3mm

53 mm

(1 5/16")

(2 3/32")

4.5 mm

19 mm

inside

#16 Drill (.1770)

(3/4")

4 plcs.

25.4 mm

24 mm

(1")

(15/16")

4°

88mm

89 mm

(3 15/32")

12.4 cm

(3 1/2")

(4 7/8")

84mm

76 mm

(3 5/16")

(3")

36 mm

(13/32")

33.3 mm

Ref.

See

(1 5/16")

SK-A

24 mm

14°

12.7 cm (5")

Left Side

(15/16")

Front

38 mm

(1 1/2")

17.1 cm (6 3/4")

inside

45°

11 mm

inside

11 mm

Right Side

(7/16")

(7/16")

13 mm

6.4 mm

(1/2")

(1/4")

inside

Typ.

SK-A

Bottom

Figure 4-2 Printer Bracket Mounting Dimension

Page 18 of 123

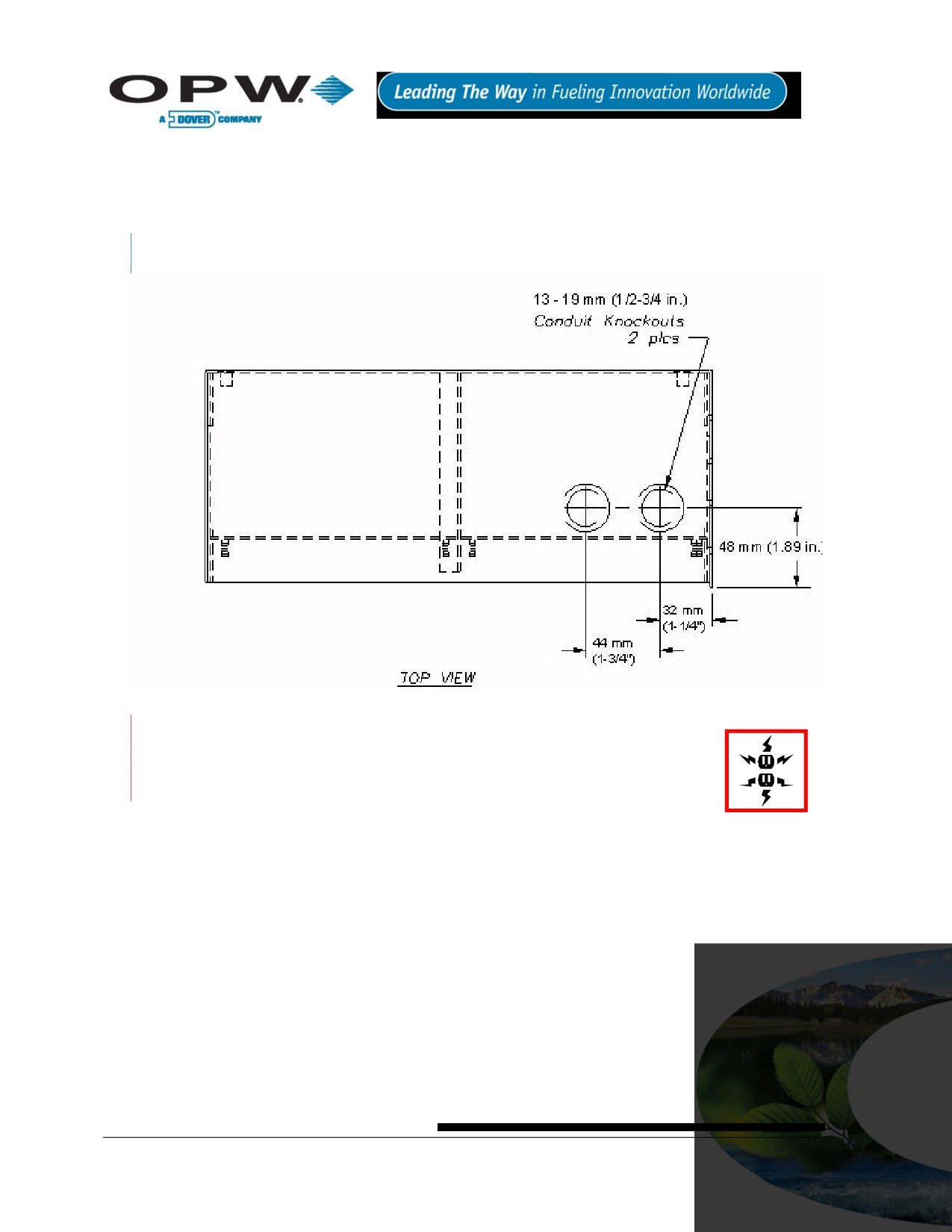

4.3 Installing the Controller Power Supply Conduit

A local circuit breaker/disconnect device must be installed close to the controller. Run conduit from this local

breaker back to the main site distribution panel. Install 13 mm (0.5 in) rigid steel conduit from the local circuit

breaker panel to the top right controller knockout, Figure 4-3 below.

The left knockout is reserved for optional external alarm wiring.

Figure 4-3 Controller Conduit Knockouts

Do not connect the controller to equipment that exceeds the maximum ratings of

voltage and current as specified in Specifications on page 13. Probe cables and

sensor wiring must not share conduit with any other wiring.

Page 19 of 123

4.4 Wiring the Controller Power Supply

The power supply automatically adjusts for supply voltages from 100 to 250 VAC

1. Pull two #14 AC power wires and one #12 AWG ground wire through the conduit from the distribution

panel to the local breaker dedicated to the controller.

2. Pull two #14 AC power wires and one #12 AWG ground wire through the conduit from the local

breaker to the controller.

3. Pull just enough wire through the bushing to attach to the 3-pin green terminal block located on the

right of the controller circuit board.

Connect AC neutral and AC hot wires (order not important) to pins 1 and 3 of the green terminal block.

Center pin is not used. Attach the cover to the terminal block.

4. Attach the ground wire to one of the ground terminal studs (near the top knockouts marked as ground)

and run back to the main distribution panel for connection.

The ground wire must be #12 AWG or larger.

Some countries/states require a redundant ground wire; this should be attached to the second ground

terminal stud and run back to the main distribution panel for connection.

Power wiring must enter the controller via the designated power conduit knockout.

Connect the power wires to a dedicated circuit.

See Specifications on page 12 for power requirements.

Protecting communication ports and ensuring site intrinsic safety for the SiteSentinel® iTouch™

Proper Grounding of the SiteSentinel® iTouch™ is essential for protecting the communication ports and

lessens the risks of hazardous situations occurring when power surges or lightning strikes happen. This

document outlines the recommended practices for a safe and damage-free installation.

Page 20 of 123

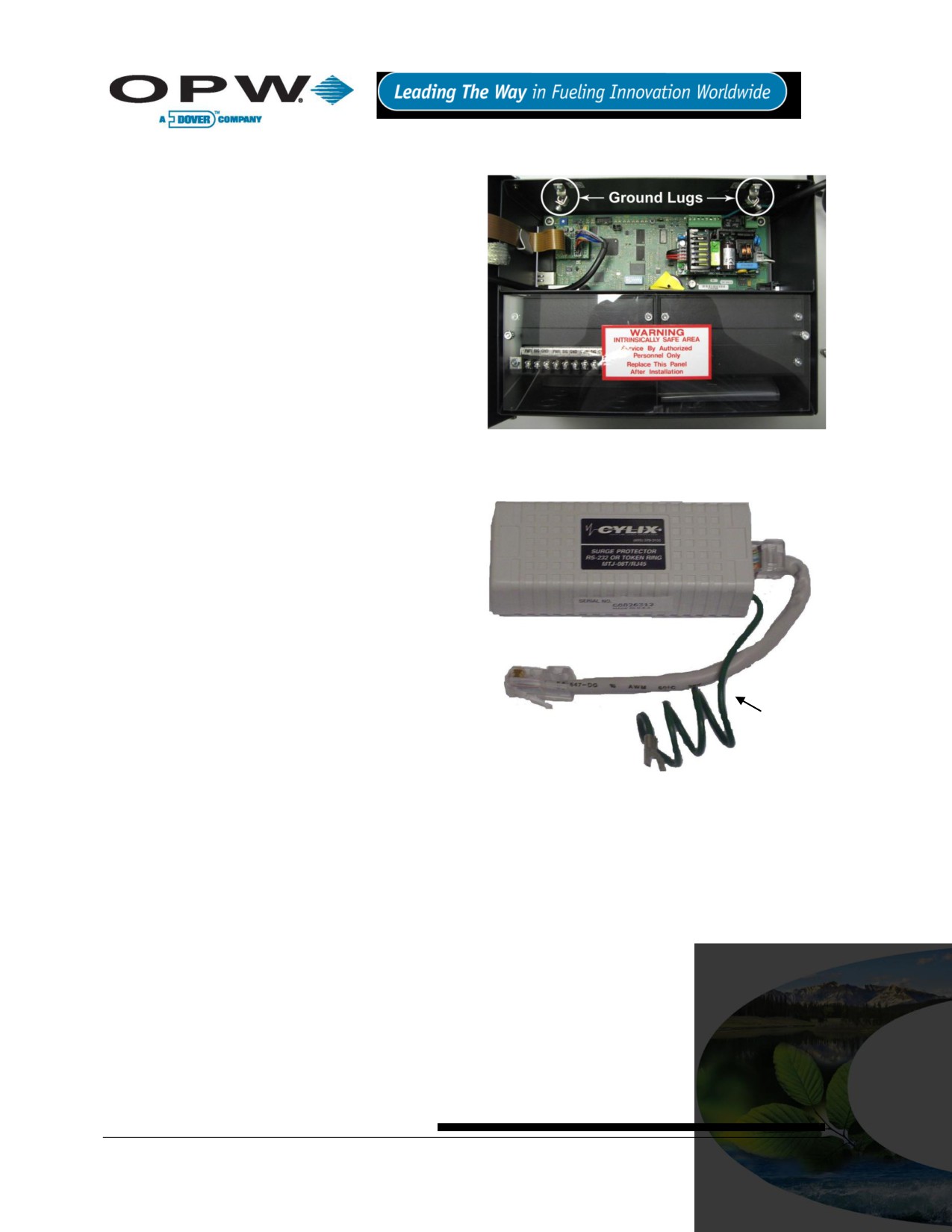

4.4.1 Grounding the SiteSentinel® iTouch™ Tank Gauging System

There are two ground lugs within the SiteSentinel®

iTouch™ (See Figure 4-4 below) You will need to

install two continuous ground wires (green 12 AWG or

larger) from both ground lugs connected back to the

distribution panel ground. The intrinsic barriers rely on

these ground connections; if they are not present the

barriers will not work. The redundant ground ensures

that the SiteSentinel® iTouch™ will operate properly

and safety.

4.4.2 SiteSentinel® iTouch™ Port

Protection

The communication ports can be damaged by ground

faults within the SiteSentinel® iTouch™. If you are

communicating from another type of system, such as a

Figure 4-4 SiteSentinel® iTouch™ Ground Lugs

point-of-sale (POS) system, to the SiteSentinel®

iTouch™ and there is a slightly ground potential

difference, this difference will either cause

immediate failure of the SiteSentinel® iTouch™, or

will cause a failure over time. To eliminate this

possible damage, make sure the other equipment

is grounded back to the same ground potential as

the SiteSentinel® iTouch™ at the distribution panel.

In addition, a 12 AWG or larger wire can be run

from the ground lug in the SiteSentinel® iTouch™

to the ground of the other equipment.

OPW Fuel Management Systems can supply an

external surge suppressor (Part # 75-0104), see

Figure 4-5 to the right. This device will help protect

the ports from power surges or lightning strikes.

Ground Wire

Figure 4-5 SiteSentinel® iTouch™ External Surge Protector (75-

0104)

Page 21 of 123

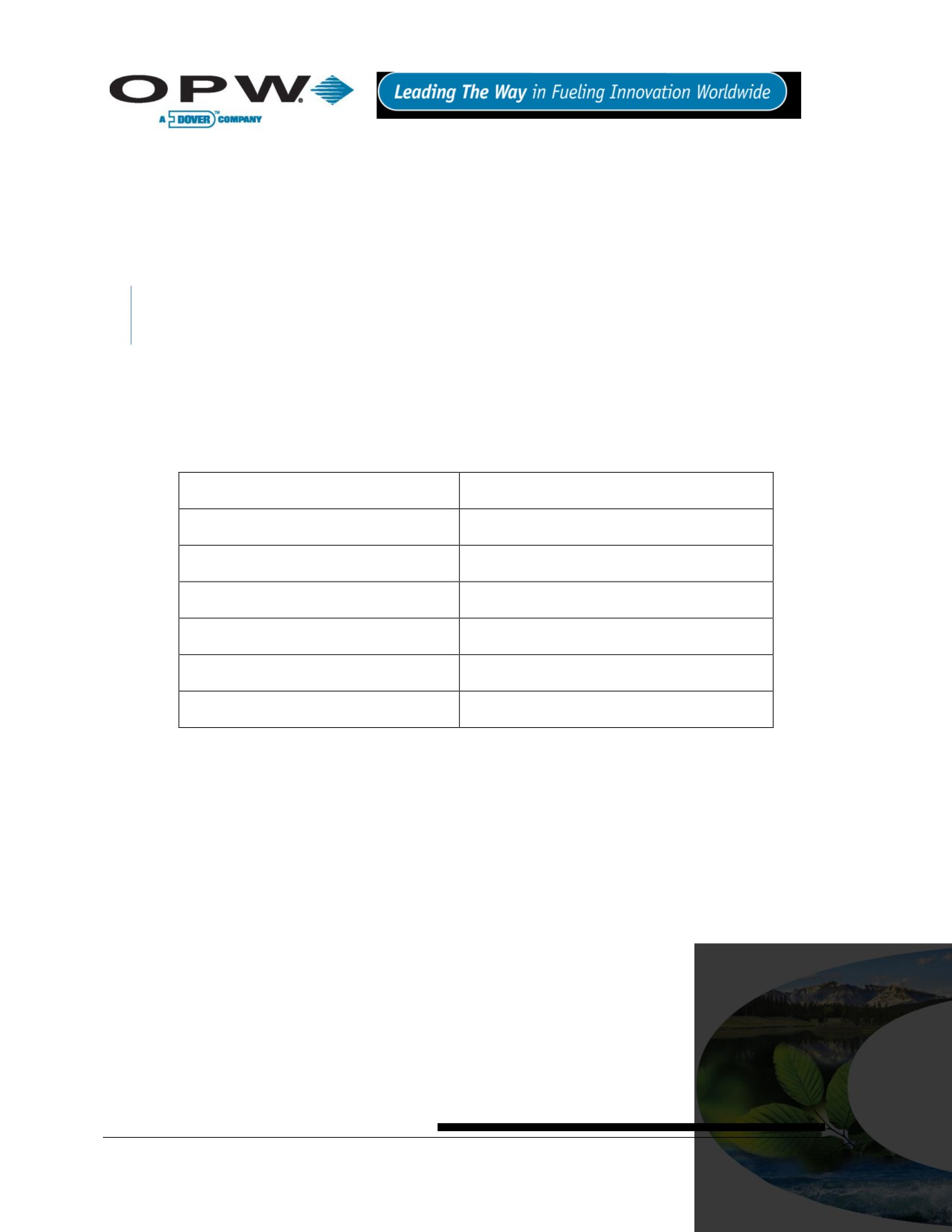

To install, simply insert the surge protector in series

between the incoming communication lines and the

I/O port of the SiteSentinel® iTouch™ (See Error!

eference source not found.). The surge protector

ground wire must be connected to the metal chassis

of the SiteSentinel® iTouch™ or to the ground lug

within the SiteSentinel® iTouch™. Each port requires

one surge protector.

Figure 4-6 SiteSentinel® iTouch™ External Surge

Protector I/O Port Connection (75-0104)

Page 22 of 123

5 Preparing for Probe and Sensor Installation

5.1 Probe and Sensor Wiring

5.1.1 Compliance

Installation of this equipment must be in accordance with all local, state and federal regulations pertaining to

this type of equipment including, but not limited to, the National Electrical Code, NFPA No. 70 and the

Automotive and Marine Service Station Code, NFPA No. 30A.

5.1.2 Wire Type

All wiring should have a capacitance rating of less than 100 picofarads per foot.

5.1.3 Probe Wiring

Gas and oil-resistant shielded, 2-conductor cable is required to extend the probe cable to the I.S. Interface

Module in the Controller. OPW Fuel Management Systems recommends you use Belden #88760 or Alpha

#55371 cable.

Belden #88760 is available directly from OPW Fuel Management Systems; part #12-1300

5.1.4 Sensor Wiring

You can use the same cable as used for the probe or you can use individual gas and oil-resistant cable,

providing it is 18 AWG or greater.

5.1.5 Wire Length

Wire runs must be less than 300 m (984 ft) to meet intrinsic safety standards. Also, wire lengths of 300 m (984

ft) or more between probe/sensor and the controller will jeopardize signal integrity and system operations.

5.1.6 Wire Splices

There should be no splices between the field junction box and the I.S. Interface Module in the SiteSentinel®

iTouch™ Controller. A splice in the hazardous area requires the use of a silicon-filled wire nut that must be

located in a waterproof junction box. Each splice would jeopardize signal integrity and system operations.

Page 23 of 123

5.2 Conduit

All probe and sensor cabling to the SiteSentinel® iTouch™ Controller must be in rigid steel conduit. The conduit

must be dedicated to intrinsically safe wiring for this controller.

Probe and sensor wiring for this controller can share the same conduit.

This controller’s intrinsically safe wiring cannot share the same conduit with other equipment’s intrinsically safe

wiring.

PVC conduit may be substituted for rigid steel conduit where acceptable by local codes. Use SHIELDED

cable for sensor and probe wiring as described in the above sections.

The size and number of probe and sensor conduits (probe sensor-to-controller) depends on how many probes

and sensors your site has.

See Table 5-1 below. Try to group probe wires into separate conduits for each SiteSentinel® iTouch™

Controller I.S. Interface Module position.

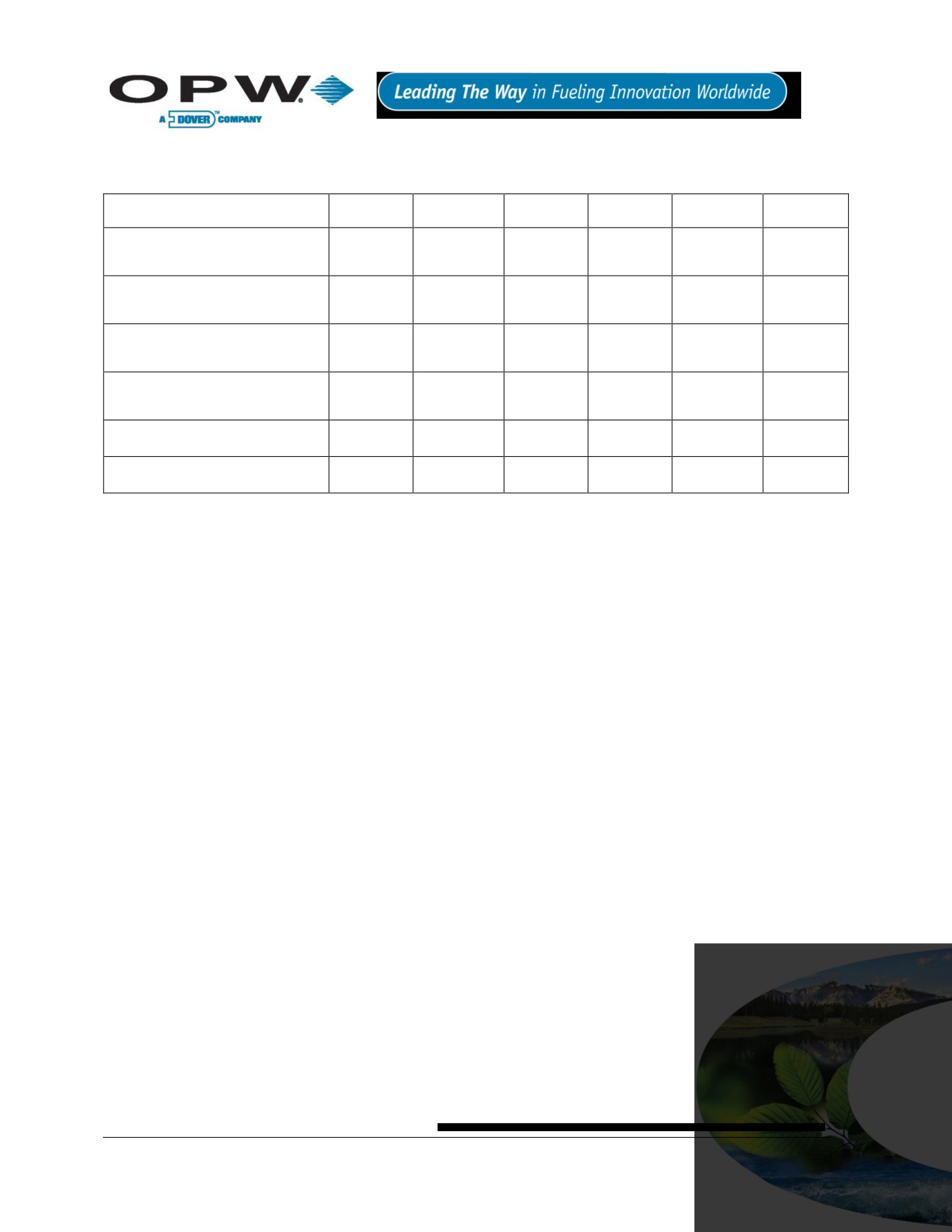

Table 5-1 Probe Quantity vs. Conduit Capacity

Number of Probes

Number & Size of Conduits

1 to 2

3 to 4

One 19 mm (0.75 in)

5 to 6

One 13 mm (0.5 in) and one 19 mm (0.75 in)

7 to 8

Two 19 mm (0.75 in)

9 to 12

Three 19 mm (0.75 in)

13 to 16

Four 19 mm (0.75 in)

Page 24 of 123

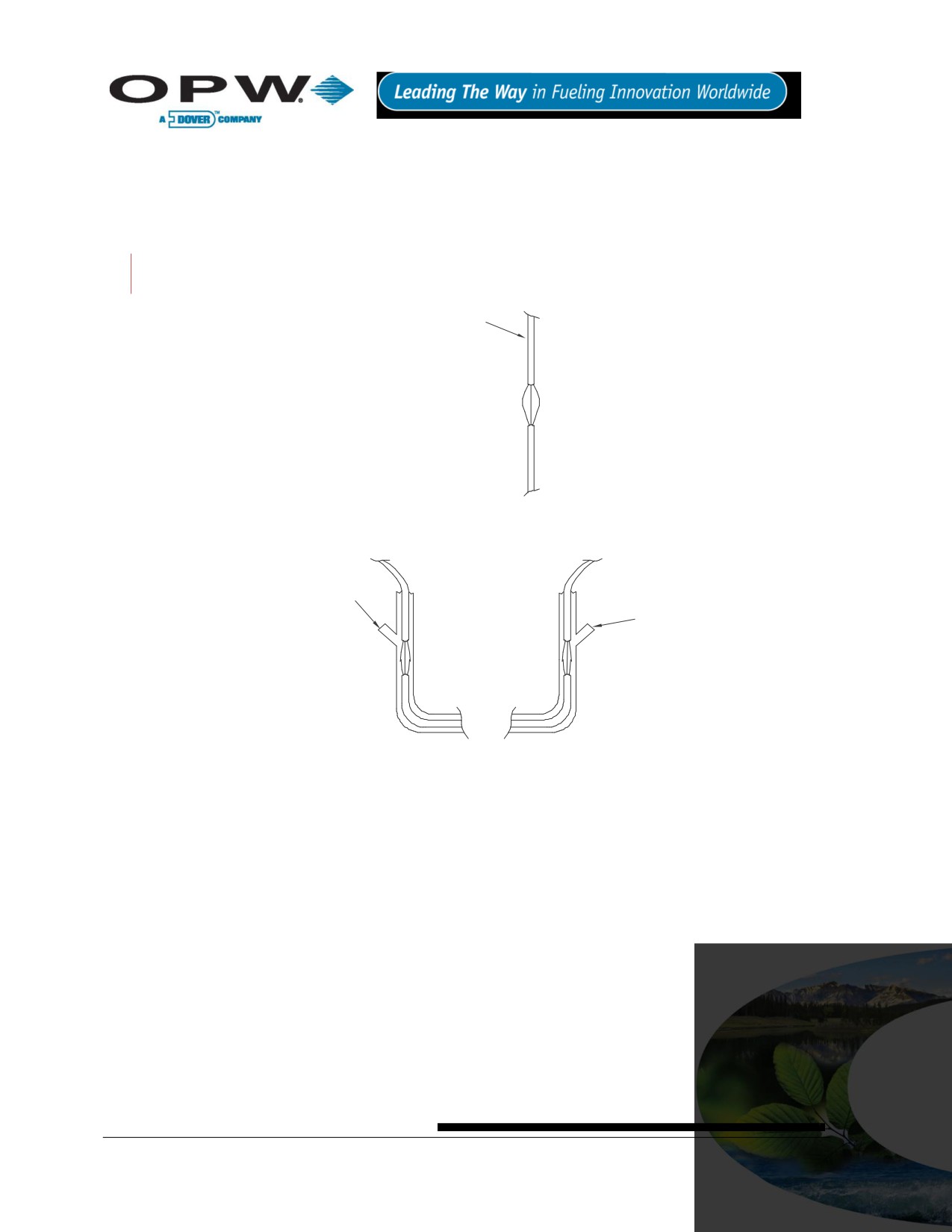

6 Seal-Offs

Seal off probe and sensor cables at both ends of the conduit run (Figure 6-1 below). Seal-offs prevent

explosive vapors from entering the controller or the building. Remove enough of the outer wire jacket to allow

approximately three (3) inches of wire leads to extend past each seal-off.

DO NOT nick the wire insulation.

SHIELDED CABLE

BELDEM #88760

OR ALPHA #55371

REMOVE 6" OF JACKET

AND FOIL. MAKE SURE

THE INSULATION ON

THE CONDUCTORS IS

NOT CUT AND THAT

THE GROUND WIRE IS

NOT BROKEN

TO PROBE/SENSOR

FROM PROBE OR SENSOR

MODULE

SEAL-OFF

SEAL-OFF

THE STRIPPED CABLE SECTION

MUST BE LOCATED WITHIN THE

SEAL OFF AREA.

#390198A5

Figure 6-1 Creating a Seal-Off

6.1 Junction Boxes

Weatherproof electrical junction boxes with a gasket-equipped cover are required at the end of each probe and

conduit run at the UST manhole or monitoring well location.

Wires coming off of a probe or sensor connect to prepared Belden or Alpha cable, and then go through an NPT

bushing into the weatherproof junction box. Bushings must be used in all junction boxes. The cable is then

routed out of the junction box via rigid steel conduit.

Page 25 of 123

7 Preparing Your Tanks for Probes

Figure 7-1 Underground Tank Manholes

7.1 Underground Tank Manholes

1. Excavate a 50 cm (20 in) minimum diameter manhole around an unused fitting in the top of the tank.

The hole must be big enough for a weatherproof junction box. If this fitting is not in the center of the

tank, you must take additional measurements for probe compensation (refer to Product Float and

Water Float Offsets on page 28).

2. Install a 7.5 cm - 10 cm (3 in - 4 in) diameter riser pipe in the fitting. This pipe must be long enough to

accommodate the probe head, and it must be large enough to accommodate the probe head, and it

must be large enough to accommodate the probe floats. Five cm and 10 cm (2 in and 4 in) floats are

available.

3. Install a weatherproof junction box with 13 mm (0.5 in) knockouts near the riser pipe. The junction box

must be close to the riser to allow the probe cable to reach.

4. Install a 13 mm (0.5 in) bushing in the junction box.

5. Install an adapter collar onto the tank’s riser pipe.

Use a riser cap with a suitable cable bushing installed. For older Model 924 and 613 probes, use a bushing

with an inner diameter of 11 mm (0.43 in). For next-generation 924, use bushings with an inner diameter of 5

mm (0.2 in).

Page 26 of 123

7.2 Precision Leak Test

Perform a precision leak test on each tank - especially older ones - before installing the SiteSentinel®

iTouch™. You can perform a pressurized leak test on a tank after probe installation; however, DO NOT exceed

20-psi pressure.

7.3 Probe Placement

Try to install the probe as close to the center of the tank (Figure 7-2, below) as possible. Locate the probe at

least 91 cm (about 3 ft) from the tank fill pipe. Adjust the drop tube of the fill pipe so that the product flow is

diverted away from the probe.

Figure 7-2 Probe Placement in Tank

Page 27 of 123

8 Product Float and Water Float Offsets

The 924 probes differ slightly in setup from previous models of probe. This section tells you how to match your

manual dipstick tank readings to the readings from the probe. Offset compensates for the angle (or slope) that

the tank may have.

When performing subtractions, remember that subtracting a negative number is the same as adding the

positive version of that number. For example, subtracting -2 from 6 results in 8.

8.1 Offset Procedure

An example appears below:

1. Run the SiteConnect™ software. Set both the Product Float Offset and the Water Float Offset held

in the SiteSentinel® iTouch™ Controller to zero (0).

2. Using your normal dipstick access point in the tank, take a Dipstick Product Level and a Dipstick

Water Level. To take the Dipstick Water Level, use water detect paste on the bottom of the dipstick.

3. Take an inventory reading from the controller. Note the Probe Product Level and the Probe Water

Level.

4. Calculate Product Float Offset and Water Float Offset:

5. Product Float Offset = (Dipstick Product Level - Probe Product Level)

6. Water Float Offset = (Dipstick Water Level - Probe Water Level)

7. Run SiteConnect™ software and configure the SiteSentinel iTouch Controller with the new offset

values obtained in the previous step.

8. Take an inventory reading from the controller. The Probe Product Level should now match the

Dipstick Product Level and the Probe Water Level should now match the Dipstick Water Level.

A typical Product Float Offset is 7.4 cm (2.9 in) and a typical Water Float Offset is 0 cm.

8.1.1 Float Offset Example

Sample DIPSTICK Levels

Product = 59.5

Water = 1.2

Sample PROBE Levels

Product = 56.6

Water = 1.5

Using this data and this equation: Dipstick Product Level = Probe Product Level = Product Float Offset,

the product offset value is 59.5 - 56.6, or 2.9.

Using this data and this equation: Dipstick Water Level - Probe Water Level = Water Float Offset, the water

offset value is 1.2 - 1.5, or -0.3

Page 28 of 123

8.2 Calculating Tank Tilt and Offset Factor

You can calculate a product offset for a probe that is not installed in the center of a “pitched” tank. Pitch is the

tilt of a tank along its horizontal axis. Some tanks are intentionally installed with one end lower than the other.

This allows water and sediment to collect at the low end, while clear product is drawn from the high end. Pitch

can also be caused by tank settling. The rate of pitch can be measured by using a dipstick to measure the level

of product at two points (preferably opposite ends) of the tank (See Figure 8-1 below). The product depth at the

deep (lower) end of the tank is value “A”. The product depth at the shallow (higher) is value “B”. The distance

between the two measuring points is “C”.

Figure 8-1 Calculating Tank Tilt

The formula for pitch is: (A-B)/C

For example: [(46” - 40”)/120”] = (6/120) = 0.05

To calculate the product offset, measure value “D”, the distance of the probe from the center of the tank. The

formula for product offset is “D” x pitch. For the example above, 36” x 0.05 = 1.8”

If the probe is located closer to the shallow end of the tank, the product offset is positive; for the example, 1.8. if

the probe is located closer to the deep end of the tank, the product offset is negative; for the example, 1.8.

See SiteConnect™’s Help for details about entering the product offset.

Page 29 of 123

9 Probes

This section covers gasoline and diesel probes. For information on the optional LPG (liquefied petroleum gas)

probe, see Appendix F - LPG Probe Option on page 91.

9.1 Probe Floats

The terms “float” and “level indicator” are completely interchangeable.

9.1.1 Product Level vs. Water Level

Figure 9-1 on page 31 shows how the probe components work together. The Product Level Indicator floats

atop the gasoline or diesel fuel and registers the overall height of the fuel. You can use the Product Level

Indicator with or without a Water Level Indicator.

The Water Level Indicator features one of two different ballast weights (color-coded for gasoline or diesel - see

Figure 10-1 on page 33). Because fuel products are less dense than water, the weight plate forces the Water

Level Indicator to sink through the product and float on the water. Water height at the product/water boundary

can thus be determined.

9.1.2 Water Float Weight Specification

If you ordered a Water Level Indicator the weight and fluid product group will be on a label affixed in the area

below. Each weight is certified by an OPW Fuel Management Systems technician for use with its Water Level

Indicator. The listed weight is the complete weight of the level indicator.

9.1.3 Installing the Float(s)

1. Review Figure 9-1 on page 31.

2. Remove the retaining ring from the probe shaft.

3. Install the level indicator(s) as shown.

4. Make sure the Water Level Indicator (if used) magnet faces UP.

5. Install probe end boot.

6. Make sure the Product Level Indicator magnet faces DOWN.

7. Replace the retaining ring through the slot in the probe end boot.

If the wrong type of water float is used, it may float to the top and register an unusually high water level,

not register at all or sink too far and register an unusually low water level. If your product fluid density

does not fit into one of these groups, contact the OPW Fuel Management Systems customer sales

department for recommendations.

Page 30 of 123

10 Product Density & Chemical Compatibility

Table 10-1 Product Compatibility

Product Group

Compatibility

API

Specific Gravity

Gasoline

Aviation Gasoline

Regular Unleaded

Regular Leaded

Gasoline (white core)

45 < API < 78

0.68 < d < 0.80

Premium Unleaded

Gasoline/Methanol blend,

less than 5% methanol

Gasohol, less than 40%

ethanol

Table 10-2 Product Compatibility (continued)

Product Group

Compatibility

API

Specific Gravity

Diesel

Jet Fuel

Kerosene

Motor Oil

Diesel (Black core)

26 < API < 45

0.80 < d < 0.90

Toluene

Gear Oil

Transmission Oil

If the float is used in a non-compatible fluid, swelling, cracking and dissolving may occur, leading to

failure. If your product is not chemically compatible with the floats, contact OPW Fuel Management

Systems Customer Service for recommendations.

Page 32 of 123

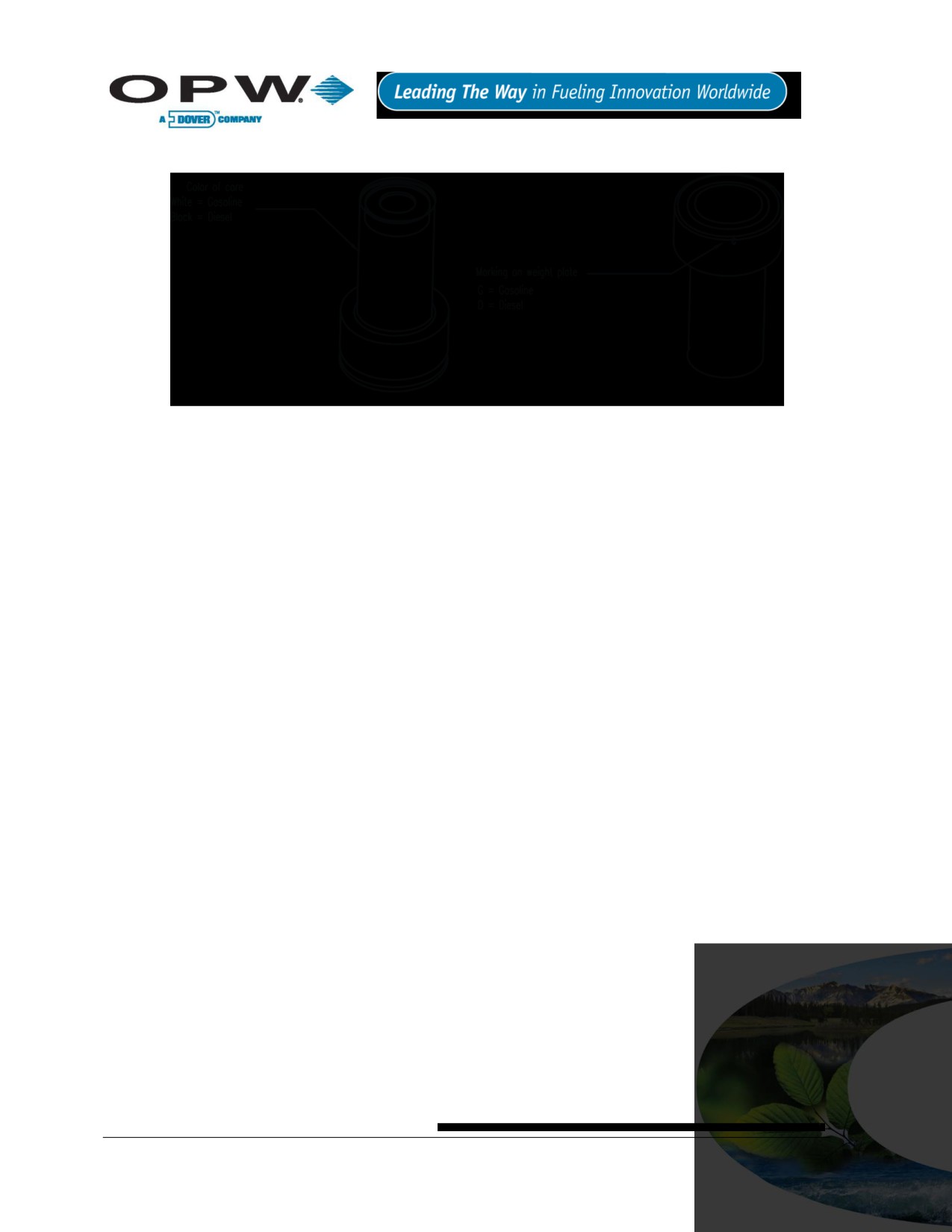

10.1 Determining Water Float Product Group

Figure 10-1 Determining Water Level Indicator Type

The Water Float/Level Indicator (Figure 10-1 above) features a ballast weight plate. This weight permits the

level indicator to sink through the product, but to float on the water, thus registering the height of the water at

the product/water boundary. The weight is certified by OPW Fuel Management Systems for use with one of the

two groups - gasoline group OR diesel group. You can tell which product the Water Level Indicator is for by the

color of the core (Figure 10-1). White cores are for gasoline, black cores are for diesel. There is also a mark on

the ballast weight plate (“G” for gasoline, “D” for diesel).

Page 33 of 123

11 Part Numbers

Table 11-1 Part Numbers

Item and Part #

30-1508-01

30-1508-02

30-1508-03

30-1509-01

30-1509-02

30-1509-03

Product level indicator assembly, 2

X

X

X

in (30-0113)

Water level indicator assembly, 2

X

X

in gas (30-0111)

Water level indicator assembly, 2

X

X

in diesel (30-0112)

Cable, 3 pole, 22 gauge, 6 ft, Blue

X

X

X

X

X

X

(10-1185)

Wire nut silicon-filled (10-5014)

X

X

X

X

X

X

Probe end boot (50-3092)

X

X

X

X

X

X

Page 34 of 123

12 Probes Wiring

Probe conduit must be dedicated to intrinsically safe wiring.

Use Table 12-1 below and Figure 12-1 on page 36 (for two-conductor cable) or Table 12-2 below and (for

three-conductor cable) to connect the probe to the Controller IS Interface Module terminal blocks.

See Figure 2-1 on page 12 for a probe drawing.

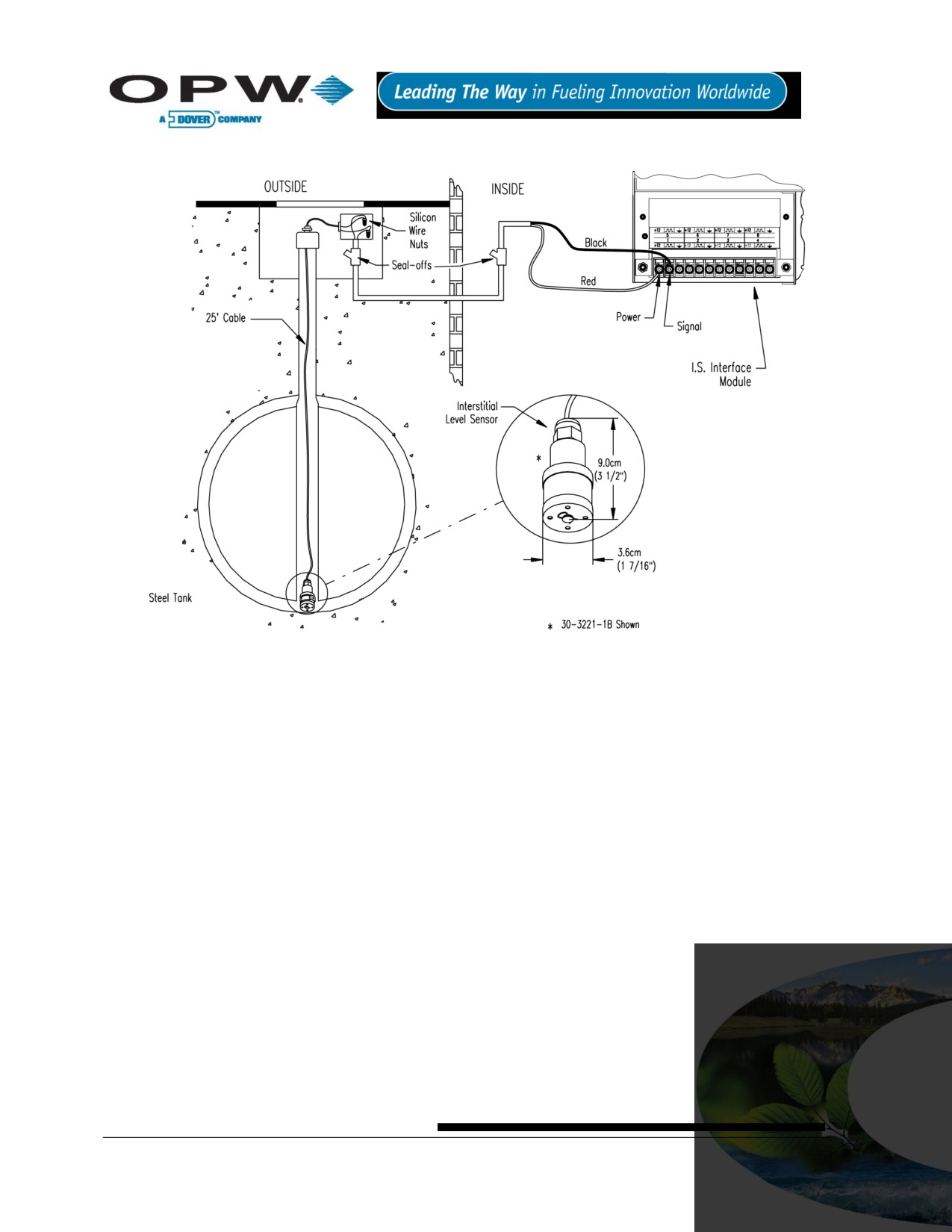

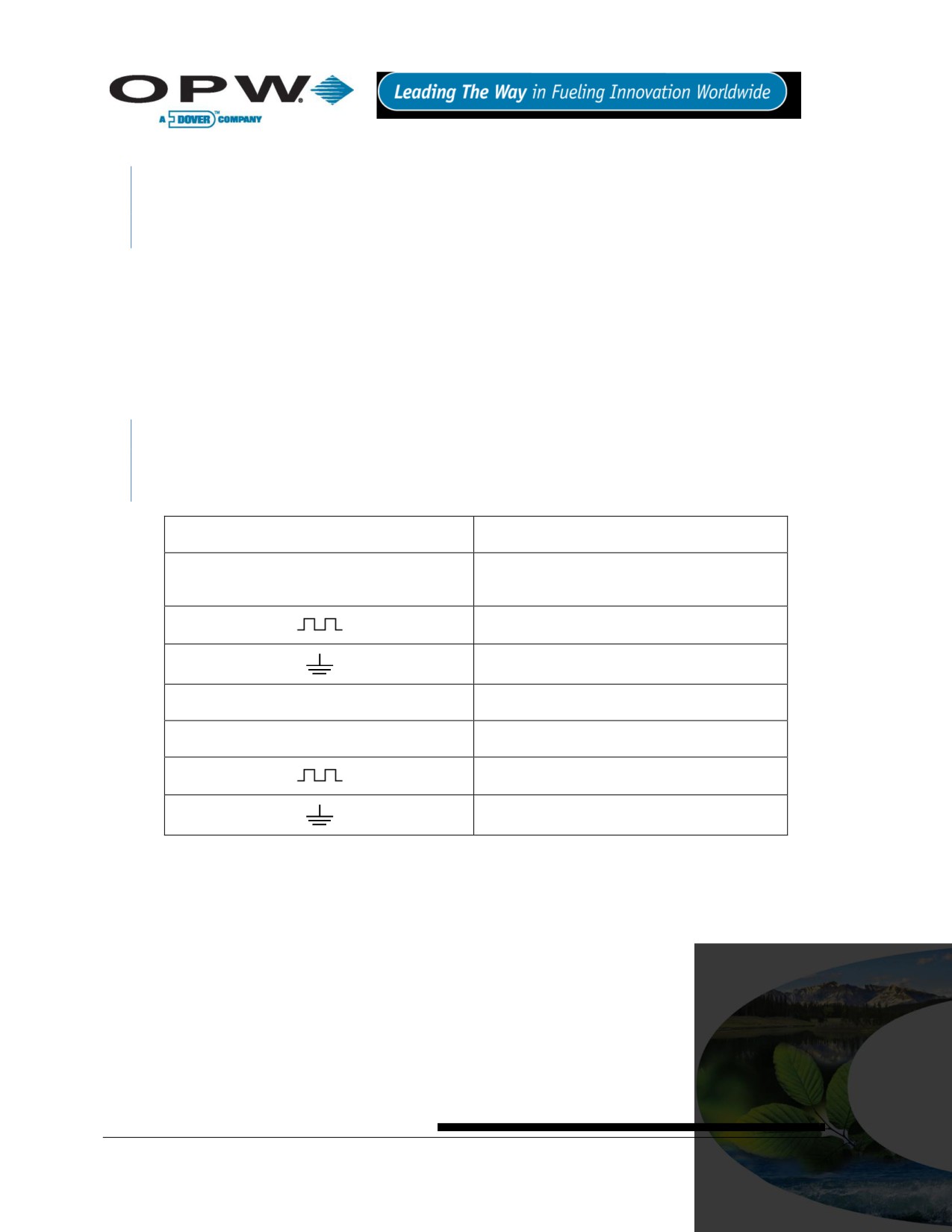

Table 12-1 I.S. Interface Module Connections to Belden TWO-CONDUCTOR Cable with Shield

I.S. Interface Module Terminal Position

Belden Cable

Probe Cable

+12 V

Red

Blue

(SIGNAL)

Black

Brown

Shield

Black & Shield

(GROUND)

Table 12-2 I.S. Probe Connections to Belden THREE-CONDUCTOR Cable

I.S. Interface Module Terminal Position

Belden Cable

Probe Cable

+12 V

Red

Blue

(SIGNAL)

Black

Brown

Shield

Black & Shield

(GROUND)

Page 35 of 123

Figure 12-1 Probe Connections - TWO Conductor Shielded Cable

With three-conductor cable, attach the shield from the cable ONLY TO THE CONTROLLER. Trim and tape

the other end of the shield. Do NOT allow the shield to touch any of the probe wires OR the metal

junction box.

Step-by-Step Procedure

1. Feed the blue probe cable through the bushing in the riser cap.

2. Attach the cable connector to the socket in the probe head.

3. Carefully lower the probe into the riser pipe until it rests on the bottom of the tank. Be careful not to

damage the floats.

4. Tighten the riser cap bushing, leaving enough cable to reach the junction box.

5. Snap the riser cap in place. Secure the cap with a lock.

6. Install a 13 mm (0.5 in) NPT bushing into the junction box.

7. Pass the probe cable through this bushing into the box, and then tighten the bushing.

8. Pull the shielded cable through the rigid conduit and through the installed seal-offs at both ends of the

conduit run. Leave slack in the probe wiring emerging from the ends.

9. Using the silicon-filled wire nuts included with the probe, connect the blue probe cable to the shielded

cable inside the electrical junction box.

10. Remove the clear plastic cover located over the I.S. Interface Modules inside the SiteSentinel®

iTouch™ Controller to attach the wiring from the probe conduit.

11. Connect the braided SHIELD from the Belden cable to the I.S. Module GROUND position.

12. Connect the BLACK wire to the I.S. Module SIGNAL position.

13. Connect the RED wire to the I.S. Module POWER position.

Page 36 of 123

When attaching probes to the controller, start with I.S. Module Position “1” and work toward “16.” Fill

one strip before starting another.

Write down which probe goes to each position. You will need this when you configure the SiteSentinel®

ITouch™ using the SiteConnect™ software.

Page 37 of 123

13 Sensors

13.1 Before You Begin

See local and National Electrical Codes for your location.

Ensure cabling (gas and oil-resistant OPW Fuel Management Systems part number 12-1030) back to

the controller is in conduit that is dedicated to intrinsically safe wiring.

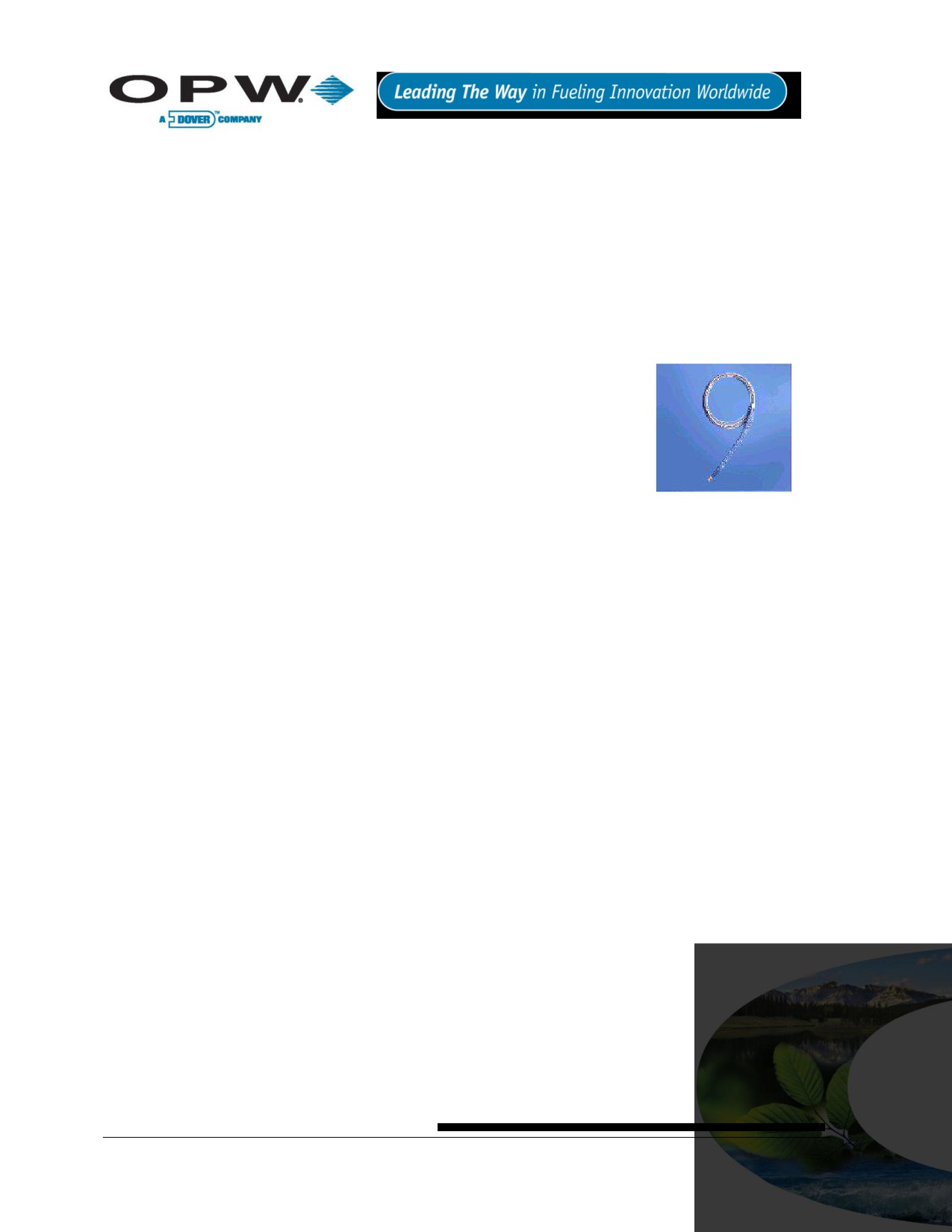

13.2 30-3206 Interstitial Hydrocarbon Liquid/Water Sensor

13.2.1 About the 30-3206

The interstitial hydrocarbon liquid/water sensor is designed for use in the

interstitial area of a double-walled tank.

The hydrocarbon liquid/water sensor contains a carbon/polymer material that

changes its resistance when exposed to liquid hydrocarbons, as well as a

water sensor that relies on the conductivity of water to detect its presence,

providing the ability to discriminate between hydrocarbon liquid and water. In

the event of a break in the cable, the system will activate the alarm.

Figure 13-1 Interstitial

Hydrocarbon Liquid/Water

13.2.2 Specifications

Sensor

Operating Temperature

-20°C to +50°C (-4°F to 122°F)

Dimensions

2.5 cm (1.0 in) x 35 cm (13.8 in)

Cable

6.1 m (20 ft) of gas & oil-resistant cable

Nominal resistance (uncontaminated)

1K -3K ohms

Nominal resistance (contaminated)

10K - 200K ohms

To ensure safe operating conditions the sensor has been designed to connect to OPW Fuel Management

Systems systems only.

Page 38 of 123

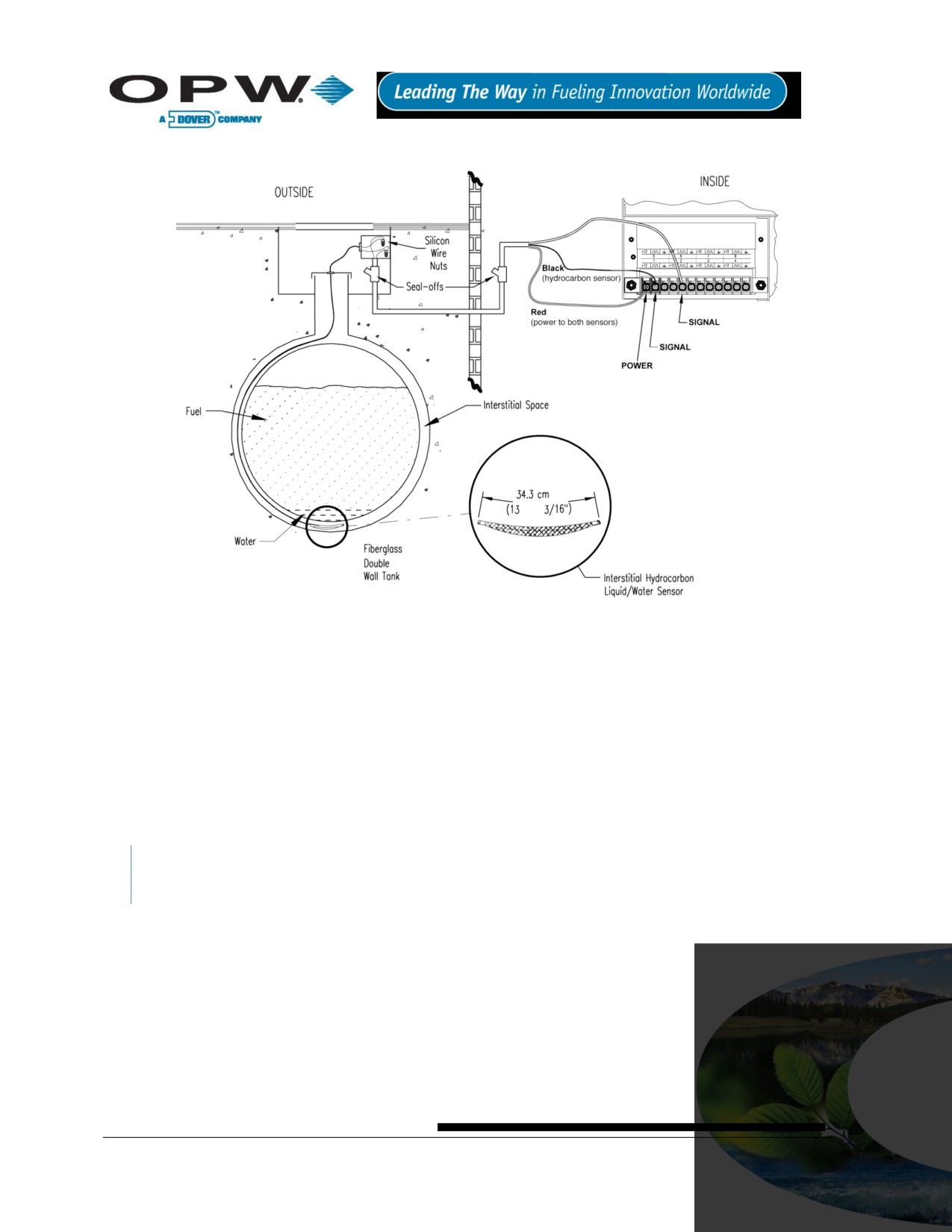

13.2.3 Installing the 30-3206

Hydrocarbons (gasoline, diesel and jet fuel, etc.) float on water; if this sensor is fully submerged, the

polymer will NOT detect hydrocarbon liquid. This sensor requires TWO (2) Controller Interface Module

Positions.

Review Figure 13-2 on page 40. Use the supplied cable gland and silicone wire nuts.

Install seal-offs at both ends of the conduit run.

13.2.4 Connections

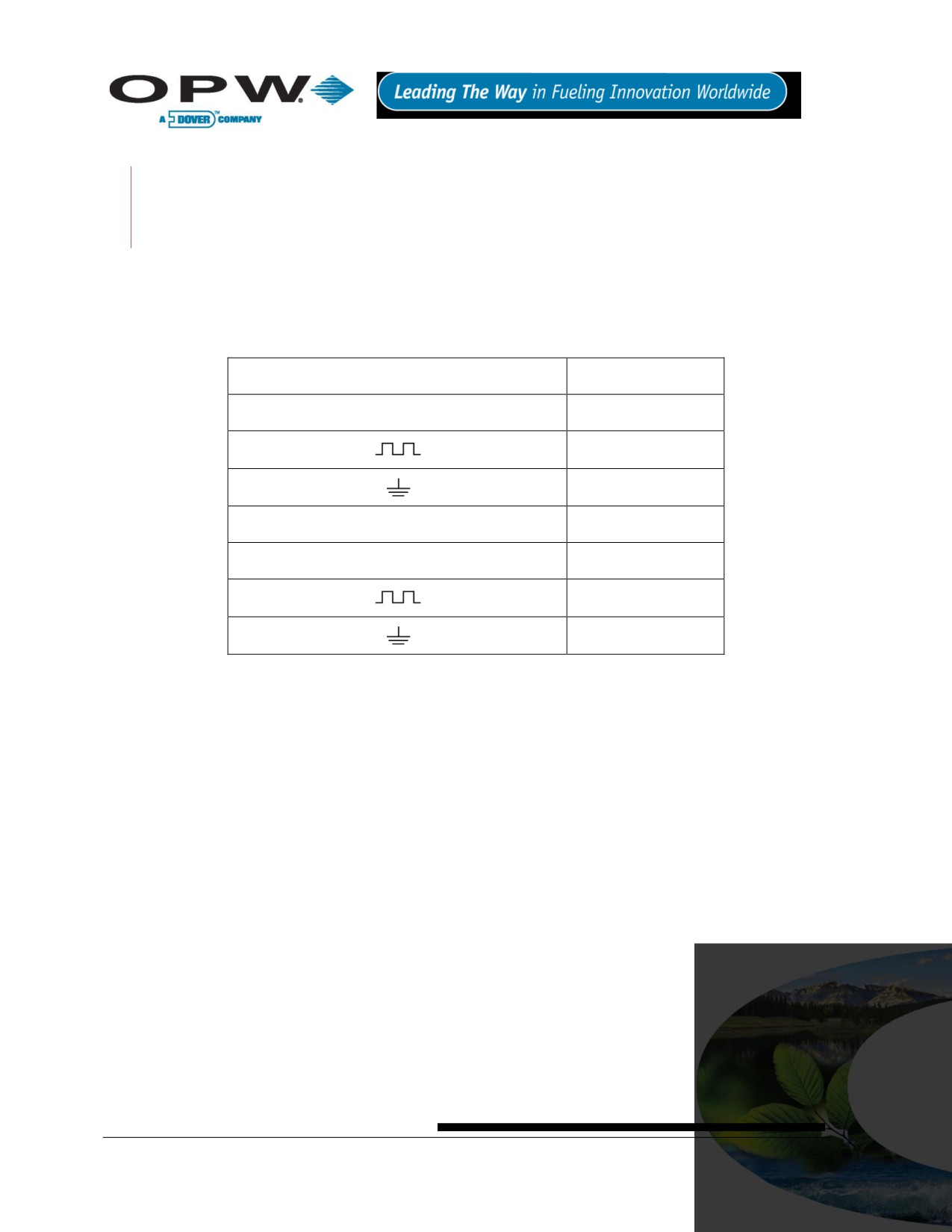

Table 13-1 Interstitial Hydrocarbon Liquid/Water Sensor Wiring

I.S. Interface Module Position 1 Terminals

Sensor Wire

+12

Red

Black (hydrocarbon)

No connection

I.S. Interface Module Position 2 Terminals

+12

No connection

White (water)

No connection

Page 39 of 123

13.2.5 Typical Interstitial Hydrocarbon Liquid/Water Sensor Installation

Figure 13-2 Interstitial (IS) Hydrocarbon Liquid/Water Sensor Installation

13.2.6 SiteSentinel® iTouch™ Controller Setup for Interstitial (“IS”) Hydrocarbon

Liquid/Water Sensor

13.2.7 1st IS Module Position - Hydrocarbon Liquid

1. Configure the barrier position to be a generic sensor (or if using SiteConnect™ choose the appropriate

icon) and install that position.

2. Using the controller, take a dynamic reading of the hydrocarbon portion of the sensor.

3. Set the lower alarm threshold to be 0.5 volts lower than the reading taken (this assumes that there is

no current hydrocarbon contamination).

SiteConnect™ will ask to adjust the lower threshold automatically, to 0.1 V below the current voltage

reading. Answer YES.

4. Set the upper alarm threshold to 5.0 volts (disables upper threshold).

5. Program the alarms associated with the lower threshold that you wish to activate if the sensor detects

hydrocarbon liquid.

Page 40 of 123

13.2.8 2nd IS Module Position - Water

1. Configure the barrier position to be a generic sensor (or if using SiteConnect™ choose the appropriate

icon) and install that position.

Set the upper alarm threshold to 0.5 volts.

2. Set the lower alarm threshold 0 volts (disables lower threshold).

3. Program the alarms associated with the upper threshold that you wish to activate if the sensor detects

water.

13.2.9 Testing and Decontaminating the Interstitial Hydrocarbon Liquid/Water

Sensor

When working in the hazardous area use caution to avoid a hazardous situation.

When testing or decontaminating the sensor, work in a well-ventilated area with no hot surfaces or open

flames. If the SiteSentinel® iTouch™ Controller fails to detect alarm conditions simulated here, also check that

your controller thresholds are correct.

Testing the Hydrocarbon Liquid Sensor Portion. Immerse the polymer in mineral spirits for about

10 minutes. Remove the sensor and let it hang to air dry. After another 10 minutes any controller

alarms or events associated with the hydrocarbon sensor should trigger. Disconnect this portion of the

sensor from the controller - an alarm should result. Short across these controller positions - an alarm

should also occur. If the open lead and/or short lead test fail, check all wiring and junction boxes for

continuity.

Testing the Water Sensor Portion. Immerse just the end of the sensor in tap water. Controller alarms

or events associated with the water portion of the sensor should trigger. Short the water portion of the

sensor - an alarm should occur. If the short lead test fails, check all wiring and junction boxes for

continuity.

Cleaning the Hydrocarbon Sensor Portion. To clean hydrocarbon contamination from the sensor

from testing or actual use, immerse the contaminated portion in denatured alcohol for one hour. Then,

flush the sensor with water to remove any residue. Leave the sensor to “settle” for another hour. The

sensor should return to nearly its original resistance, but it may be necessary to readjust the

controller’s thresholds.

Page 41 of 123

13.3 30-3207 Hydrocarbon Liquid Sensor

13.3.1 About the 30-3207-06, -10, -15

The hydrocarbon liquid sensors are used primarily in monitoring wells with

fluctuating groundwater tables. The hydrocarbon liquid sensor contains a

carbon/polymer material that changes its resistance when exposed to

liquid hydrocarbons.

Figure 13-3 Hydrocarbon Liquid

13.3.2 Specifications

Sensor

Operating Temperature

-20°C to 50°C (-4°F to 122°F)

Dimensions (depends on

1.8 cm (0.7 in) dia. x

part #)

1.8-4.6 m (6-15 ft)

Cable

3.1 m (10 ft) gas & oil-resistant cable

Nominal Resistance

Uncontaminated

1K - 3K ohms per foot

Contaminated

30K - 200K ohms

To ensure safe operating conditions the sensor has been designed to connect to OPW Fuel Management

Systems systems only.

13.3.3 Installing the 30-3207-06, -10, or -15

Hydrocarbons float on water

- if this sensor is fully submerged, the polymer will NOT detect

hydrocarbon liquid.

This sensor requires ONE Controller Interface Module position.

Review Figure 13-4 on page 43.

Use Table 13-2 below to connect the sensor to the Controller I.S. Interface Module terminals.

Use the supplied cable gland and silicone wire nuts.

Install seal-offs at both ends of the conduit run

13.3.4 Connections

Table 13-2 Hydrocarbon Liquid Sensor Wiring

I.S. Interface Module Position Terminal

Sensor Wire

+12

Red

Black

White - No connection

Page 42 of 123

13.3.5 Typical Hydrocarbon Liquid Sensor Installation

Figure 13-4 Hydrocarbon Liquid Sensor Installation

13.3.6 SiteSentinel® iTouch™ Controller Setup for Hydrocarbon Liquid Sensor

1. Configure the barrier position to be a generic sensor (or if using SiteConnect™ choose the

appropriate icon) and install that position.

2. Using the controller, take a dynamic reading of the hydrocarbon portion of the sensor.

3. Set the lower alarm threshold to be 0.5 volts lower than the reading taken (this assumes that there is

no current hydrocarbon contamination).

SiteConnect™ will ask to adjust the lower threshold automatically, to 0.1 V below the current voltage

reading. Answer YES.

4. Set the upper alarm threshold to be 5.0 volts (disables upper threshold).

5. Program the alarms associated with the lower threshold that you wish to activate if the sensor detects

hydrocarbon liquid.

13.3.7 Testing and Decontaminating the Hydrocarbon Liquid Sensor

When working in the hazardous area use caution to avoid a hazardous situation.

When testing or decontaminating the sensor, work in a well-ventilated area with no hot surfaces or open

flames.

If the SiteSentinel® iTouch™ Controller fails to detect alarm conditions simulated here, also check that your

controller thresholds are correct.

Page 43 of 123

Testing the Hydrocarbon Liquid Sensor. Immerse the polymer in mineral spirits for about 10

minutes. Remove the sensor and let it hang to air dry. After another 10 minutes any controller alarms

or events associated with the hydrocarbon sensor should trigger. Disconnect this portion of the sensor

from the controller - an immediate alarm should result. Short across these controller positions - an

alarm should also occur. If the open lead and/or short lead test fail, check all wiring and junction boxes

for continuity.

Cleaning the Hydrocarbon Liquid Sensor. To clean hydrocarbon contamination from the sensor

from testing or actual use, immerse the contaminated portion in denatured alcohol for one hour. Then,

flush the sensor with water to remove any residue. Leave the sensor to “settle” for another hour. The

sensor should return to nearly its original resistance, but it may be necessary to re-adjust the

controller’s thresholds.

13.4 30-3210-06, -10, -15 Hydrocarbon Liquid/Water Sensor

13.4.1 About the 30-3210-nn

The hydrocarbon liquid/water sensor is used primarily in monitoring wells with

fluctuating groundwater tables or in containment areas of tanks, pumps and

pipes.

The sensor contains a carbon/polymer material that changes its resistance

when exposed to liquid hydrocarbons, as well as a water sensor that relies on

the conductivity of water to detect its presence, providing the ability to

discriminate between hydrocarbon liquid and water.

Figure 13-5 Hydrocarbon

Liquid/Water Sensor

The sensor also alerts the system to the absence of groundwater in a

monitoring well or the presence of water in containment areas. It will alert the system if any fuel enters into the

containment area, which would indicate a leak. In the event of a break in the cable the system will activate the

alarm.

13.4.2 Specifications

Operating Temperature

-20°C to 50°C (-4°F to 122°F)

Dimensions (depends on part #)

1.8 cm (0.7 in) dia. x

1.8 - 4.5 m (6 - 20 ft)

Cable

3.1 m (10 ft) gas & oil-resistant

Nominal Polymer Resistance

Uncontaminated

1K - 3K ohms per foot

Contaminated

30K - 200K ohms

To ensure safe operating conditions the sensor has been designed to connect to OPW Fuel Management

Systems systems.

Page 44 of 123

13.4.3 Installing the 30-3210-06, -15, -20

This sensor requires TWO Controller Interface Module positions.

Review Figure 13-6 on page 46.

Use Table 13-3 below to connect the sensor to the Controller I.S. Module.

Use the supplied cable gland and silicone wire nuts.

Install seal-offs at both ends of the conduit run.

13.4.4 Connections

Table 13-3 Hydrocarbon Liquid/Water Sensor Wiring

I.S. Interface Module Position 1 Terminals

Sensor Wire

+12

Red

Black (hydrocarbon)

No Connection

I.S. Interface Module Position 2 Terminals

Sensor Wire

+12

No connection

White (water)

No Connection

Page 45 of 123

13.4.5 Typical Hydrocarbon Liquid/Water Sensor Installation

Figure 13-6 Hydrocarbon Liquid & Water Sensor Installation

13.4.6 SiteSentinel® iTouch™ Controller Setup for Hydrocarbon Liquid/Water

Sensor

13.4.7 Hydrocarbon Sensor Configuration

1. Configure the barrier position for the hydrocarbon sensor portion to be a generic sensor (or if using

SiteConnect™ choose the appropriate icon) and install that position.

2. With the controller, take a dynamic reading of the hydrocarbon portion of the sensor.

3. Set the lower alarm threshold to 0.5 volts lower than the reading you obtained in Step 2 (assumes no

current hydrocarbon contamination).

4. Set the upper threshold to 5.0 volts (disables upper threshold).

5. Program the alarms associated with the lower threshold that will activate in the presence of liquid

hydrocarbons.

SiteConnect™ will ask to adjust the lower threshold automatically, to 0.1 V below the current voltage

reading. Answer YES.

13.4.8 Water Sensor Configuration

1. Configure the barrier position for the water sensor portion to be a generic sensor (or if using

SiteConnect™ choose the appropriate icon) and install that position.

2. Set the upper alarm threshold to 0.5 volts. Set the lower alarm threshold to 0.0 volts (disables lower

threshold).

Page 46 of 123

13.4.9 Testing the Sensor

When working in the hazardous area use caution to avoid a hazardous situation. When testing or

decontaminating a hydrocarbon sensor, work in a well-ventilated area with no hot surfaces or open

flames.

Testing and Cleaning the Hydrocarbon Sensor. Immerse the polymer in mineral spirits for about 10

minutes. Remove the sensor and let it hang to air dry. After another 10 minutes any controller alarms

or events associated with the hydrocarbon sensor should trigger. Disconnect this portion of the sensor

from the controller - an immediate alarm should result. Short across these controller positions - an

alarm should also occur. If the open lead and/or short lead test fail, check all wiring and junction boxes

for continuity.

To clean hydrocarbon contamination from the sensor from testing or actual use, immerse the

contaminated portion in denatured alcohol for one hour. Then, flush the sensor with water to remove

any residue. Leave the sensor to “settle” for another hour. The sensor should return to nearly its

original resistance, but it may be necessary to re-adjust the controller’s thresholds.

Testing the Water Sensor. Immerse just the end of the sensor in tap water. Controller alarms or

events associated with the water portion of the sensor should trigger. Short the water portion of the

sensor - an alarm should occur. If the short lead test fails, check all wiring and junction boxes for

continuity.

Page 47 of 123

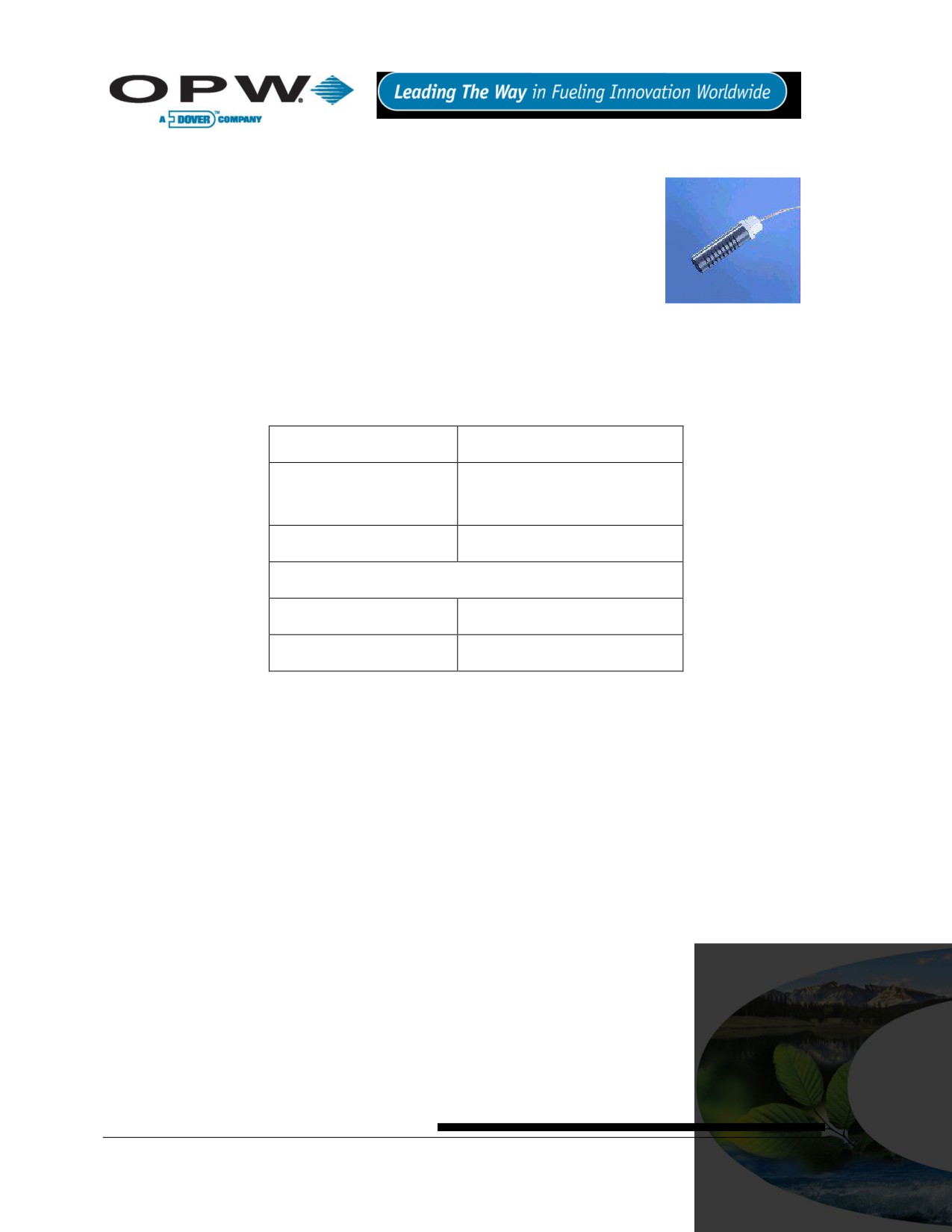

13.5 30-3219-12 Hydrocarbon Liquid Sump Sensor

13.5.1 About the 30-3219-12

The hydrocarbon liquid sump sensor is designed to detect the presence of

liquid hydrocarbons in sumps, dispenser pans and other locations where the

presence of a hydrocarbon liquid could indicate that a leak has occurred.

The hydrocarbon liquid sensor contains a carbon/polymer material that

changes its resistance when exposed to liquid hydrocarbons. In the event of a

break in the cable, the system will activate the alarm.

Figure 13-7 Hydrocarbon

Liquid Sump Sensor

13.5.2 Specifications

Operating Temperature

-20°C to 50°C (-4°F to 122°F)

Dimensions

4.4 cm (1.7 in) dia. x

33.5 cm (13.2 in) long

Cable

3.6 m (12 ft) gas & oil-resistant

Normal Resistance

Uncontaminated

1K - 5K ohms

Contaminated

30K - 200K ohms

To ensure safe operating conditions the sensor has been designed to connect to OPW Fuel Management

Systems systems only.

Page 48 of 123

13.5.3 Installing the 30-3219-12

Hydrocarbons float on water

- if this sensor is fully submerged, the polymer will NOT detect

hydrocarbon liquid.

This sensor requires ONE Controller Interface Module positions.

Review Figure 13-8 on page 50.

Use Table 13-4 below to connect the sensor to the Controller I.S. module.

Use the supplied cable gland and silicone wire nuts.

Install seal-offs at both ends of the conduit run.

13.5.4 Connections

Table 13-4 Hydrocarbon Liquid Sump Sensor Wiring

I.S. Interface Module Position

Sensor Wire

+12

Red

Black

No Connection

Page 49 of 123

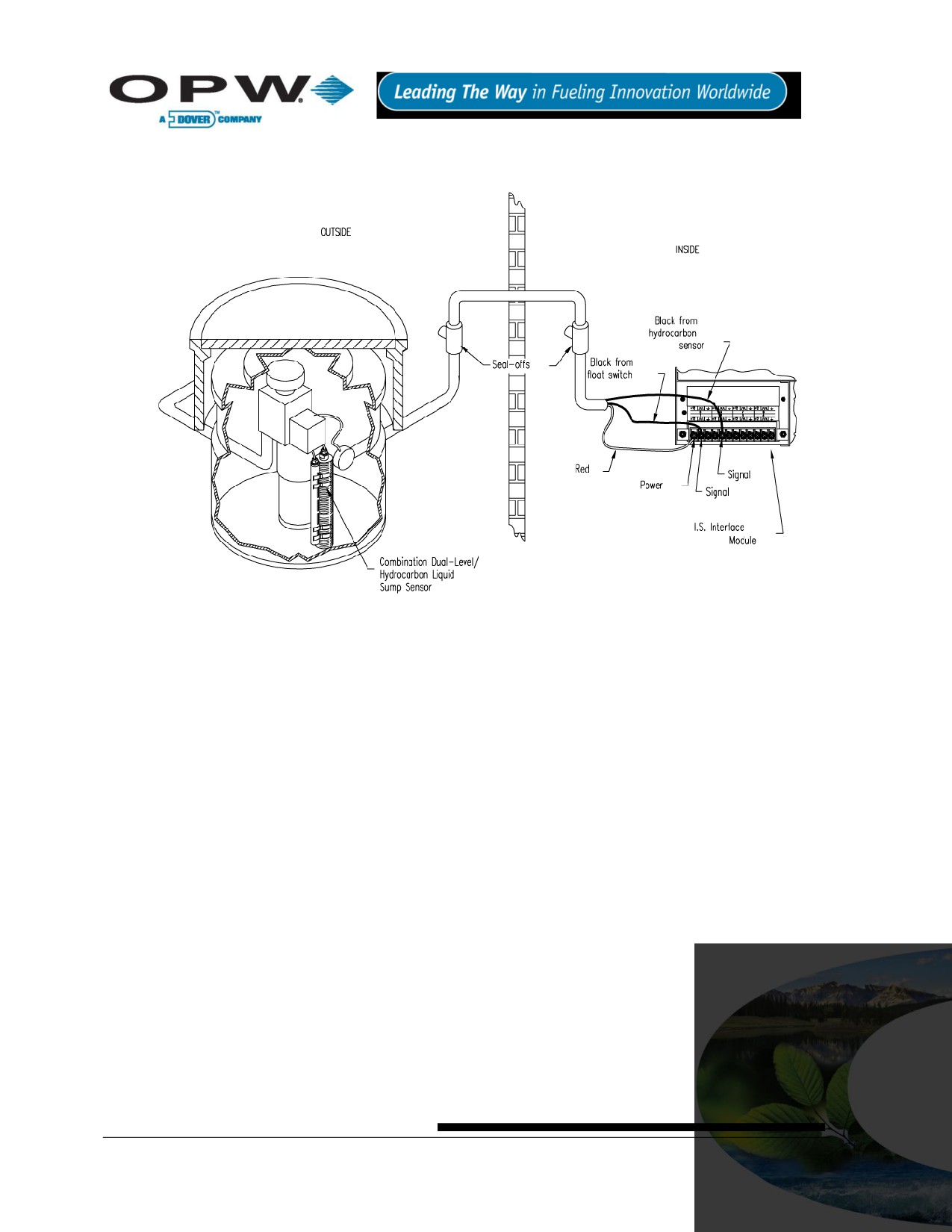

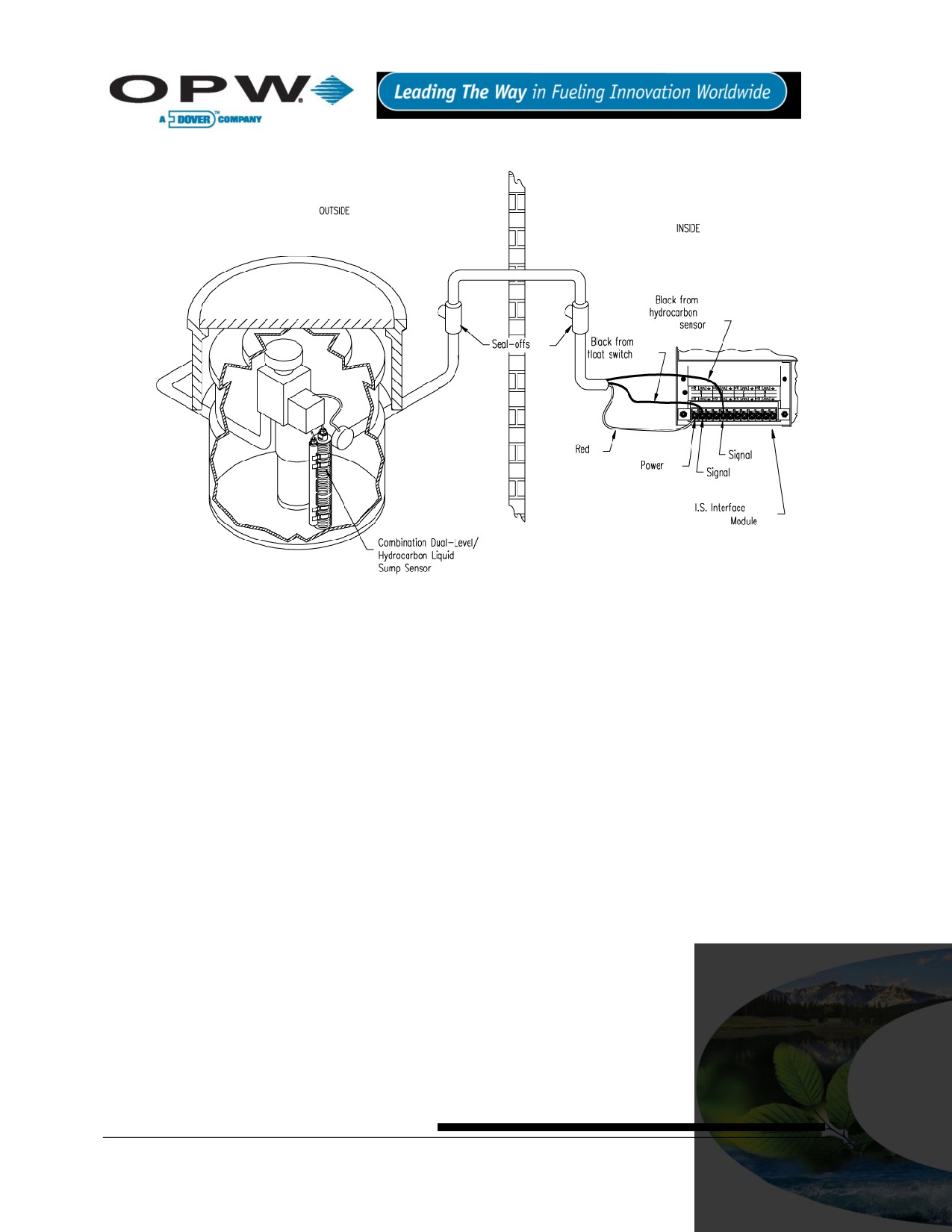

13.5.5 Typical Hydrocarbon Liquid Sump Sensor Installation

Figure 13-8 Hydrocarbon Liquid Sump Sensor Installation

13.5.6 SiteSentinel® iTouch™ Controller Setup for Hydrocarbon Liquid Sump

Sensor

1. Configure the barrier position to be a generic sensor (or if using SiteConnect™ choose the

appropriate icon) and install that position.

2. Using the Controller, take a dynamic reading of the hydrocarbon portion of the sensor.

3. Set the lower alarm threshold to be 0.2 volts lower than the reading taken (this assumes that there is

no current hydrocarbon contamination).

SiteConnect™ will ask to adjust the lower threshold automatically, to 0.1 V below the current voltage

reading. Answer YES.

4. Set the upper alarm threshold to be 5.0 volts (disables upper threshold).

5. Program the alarms associated with the lower threshold that you wish to activate if the sensor detects

hydrocarbon liquid.

Page 50 of 123

13.5.7 Testing and Decontaminating the Hydrocarbon Liquid Sump Sensor

When working in the hazardous area use caution to avoid a hazardous situation.

When testing or decontaminating the sensor, work in a well-ventilated area with no hot surfaces or open

flames.

If the SiteSentinel® ITouch™ Controller fails to detect alarms conditions simulated here, also check that your

controller thresholds are correct.

Testing the Hydrocarbon Liquid Sump Sensor. Immerse the polymer in mineral spirits for about 10

minutes. Remove the sensor and let it hang to air dry. After another 10 minutes, any controller alarms

or events associated with the hydrocarbon sensor should trigger. Disconnect this portion of the sensor

from the controller - an immediate alarm should result. Short across these controller positions - an

alarm should also occur. If the open lead and/or short lead test fail, check all wiring and junction boxes

for continuity.

Cleaning the Hydrocarbon liquid Sump Sensor. To clean hydrocarbon contamination from the

sensor from testing or actual use, immerse the contaminated portion in denatured alcohol for one hour.

Then, flush the sensor with water to remove any residue. Leave the sensor to “settle” for another hour.

The sensor should return to nearly its original resistance, but it may be necessary to readjust the

controller’s thresholds.

13.6 30-3221-1 Single-Level Sump Sensor

13.6.1 About the 30-3221-1

The single-level sump sensor is designed to detect the presence of liquid in

sumps, dispenser pans and other locations where the presence of a liquid

could indicate that a leak has occurred.

This sensor can also be used to monitor wet wells to ensure that liquid is

normally present. The sensor contains a float switch that activates in the

presence of liquid. In the event of a break in the cable, the system will activate

the alarm.

Figure 13-9 Single-Level Sump

Sensor

13.6.2 Specifications

Operating Temperature

-20°C to 50°C (-4°F to 122°F)

Dimensions

7.4 cm (2.9 in) dia x

9.5 cm (3.7 in) long

Cable

4.6 m (15 ft) gas & oil-resistant

To ensure safe operating conditions, the sensor has been designed to connect to OPW Fuel Management

Systems systems only.

Page 51 of 123

13.6.3 Installing the 30-3221-1

If monitoring a normally dry well, use a meter to orient the float so the sensor is in the closed state with

NO liquid present (float in lower position). If monitoring a normally wet well, use a meter to orient the

float so that it is in the closed state WITH liquid present (float in upper position).

This sensor requires ONE Interface Module position.

Review Figure 13-10 on page 53.

Use Table 13-5 below to connect the sensor to the Controller I.S. Interface Module terminals.

Use the supplied cable gland and silicone wire nuts.

Install seal-offs at both ends of the conduit run

13.6.4 Connections

Table 13-5 Single-Level Sump Sensor Wiring

I.S. Interface Module Position

Sensor Wire

+12

Red

Black

No Connection

Page 52 of 123

13.6.5 Typical Single-Level Sump Sensor Installation

Figure 13-10 Single-Level Sump Sensor Installation

13.6.6 SiteSentinel® iTouch™ Controller Setup for Single-Level Sump Sensor

1. Configure the barrier position to be a generic sensor (of if using SiteConnect™ choose the appropriate

icon) and install that position.

2. Set the lower alarm threshold to 2.5 volts set the upper alarm threshold to 5.0 volts (disables upper

threshold).

3. Program the alarms associated with the lower threshold to the lower threshold that you wish to activate

if the sensor detects hydrocarbon liquid.

13.6.7 Testing the Single-Level Sump Sensor Float

When working in the hazardous area use caution to avoid a hazardous situation.

When testing the senor, work in a well-ventilated area with no hot surfaces or open flames.

If Sensor Installed in a Normally DRY Well

Place the float in the UPPER position - this should trigger an alarm in the controller.

Return the float to the LOWER position - the alarm should end.

If Sensor Installed in a Normally WET Well

Place the float in the LOWER position - this should trigger an alarm in the controller

Return the float to the UPPER position - the alarm should end.

If the controller fails to register the alarm conditions, check your programmed thresholds in the controller.

Check the orientation of the float as described on page 58. Disconnecting the sensor should trigger an alarm

and shorting the sensor should be out of alarm. Check all wiring and junction boxes to ensuring continuity

without shorts.

Page 53 of 123

13.7 30-3221-2 Dual-Level Reservoir Sensor

13.7.1 About 30-3221-2

The dual-level reservoir sensor is designed for use in the brine-filled reservoir of

the interstitial area of a double-walled tank. This sensor contains a dual-level

float switch that detects level changes of fluid in the reservoir of the tank. The

sensor expects the liquid to be at a constant level. The system will activate the

alarm when the brine level in the interstitial space either rises or falls.

It can also be used in other areas (such as dispenser containment pans) that

are normally dry and will give a low-level warning followed by a high-level alarm.

Figure 13-11 Dual-Level

In the event of a break in the cable, the system will activate the alarm.

Reservoir Sensor

13.7.2 Specifications

Operating Temperatures

-20°C to 50°C (-4°F to 122°F)

Dimensions

6 cm (2.4 in) dia. x

35.6 cm (14 in) long

Cable

4.5 m (15 ft) gas & oil-resistant

To ensure safe operating conditions the sensor has been designed to connect to OPW Fuel Management

Systems systems only.

Page 54 of 123

13.7.3 Installing the 30-3221-2

The logic for this sensor can be changed by simply flipping the lower float. To remove the lower float,

use needle-nose pliers to remove the bottom clip. Then, remove the plastic cover and the float clip,

followed by the float itself.

If you are monitoring a normally wet well (brine-filled reservoir), orient the float with the CLOSED arrow pointing

downward.

If you are monitoring a normally dry well, make sure to orient the float with the CLOSED arrow pointing upward.

This sensor requires ONE Interface Module position.

Review Figure 13-12 on page 56.

Use Table 13-6 below to connect the sensor to the Controller I.S. Interface Module terminals.

Use the supplied cable gland and silicone wire nuts.

Install seal-offs at both ends of the conduit run

13.7.4 Connections

Table 13-6 Dual-Level Reservoir Sensor Connections

I.S. Interface Module Position Terminal

Sensor Wire

+12

Red

White

No connection

Page 55 of 123

13.7.5 Typical Dual-Level Reservoir Sensor Installation

Figure 13-12 Dual-Level Sump Sensor Installation

13.7.6 SiteSentinel® iTouch™ Controller Setup for Dual-Level Reservoir Sensor

1. Configure the barrier position to be a generic sensor (or if using SiteConnect™, choose the

appropriate icon) and install that position.

2. Set the lower alarm threshold to 2.2 volts. Set the upper alarm threshold to 3.4 volts.

If monitoring a normally wet well, the 3.4 volt threshold means liquid is too low. The 2.2 volt

threshold means liquid is too high.

If monitoring a normally dry well, the 3.4 volt threshold is where liquid is above the lower

float. The 2.2 volt threshold is where liquid is above the upper float.

3. Program the alarms associated with the thresholds you wish to activate if the sensor detects liquid.

Page 56 of 123

13.7.7 Testing the Dual-Level Reservoir Sensor Float

When working in the hazardous area use caution to avoid a hazardous situation.

When testing the sensor, work in a well-ventilated area with no hot surfaces or open flames.

If Sensor Installed in a Normally DRY Well

Place the LOWER float in its UPPER position and the UPPER float in its LOWER position. This should

trigger a low-level alarm in the controller.

Place the LOWER float in its UPPER position and the UPPER float in its UPPER position. This should

trigger a high-level alarm in the controller.

Return BOTH floats to their LOWER positions and check that the controller is no longer in the alarm

state.

If Sensor Installed in a Normally WET Well

Place the LOWER float in its LOWER position and the UPPER float in its LOWER position. This should

trigger a low-level alarm in the controller.

Place the LOWER float in its UPPER position and the UPPER float in its UPPER position. This should

trigger a high-level alarm in the controller.

Place the LOWER float in its UPPER position and the UPPER float in its LOWER position. Confirm

that the controller is no longer in an alarm state.

If the controller fails to register the alarm condition, check your programmed thresholds in the controller.

Check the orientation of the lower float as described on page 54.

Disconnecting the sensor should trigger a high-level alarm. Shorting the sensor should generate a low-level

alarm. Check all wiring and junction boxes to ensure continuity without shorts.

Page 57 of 123

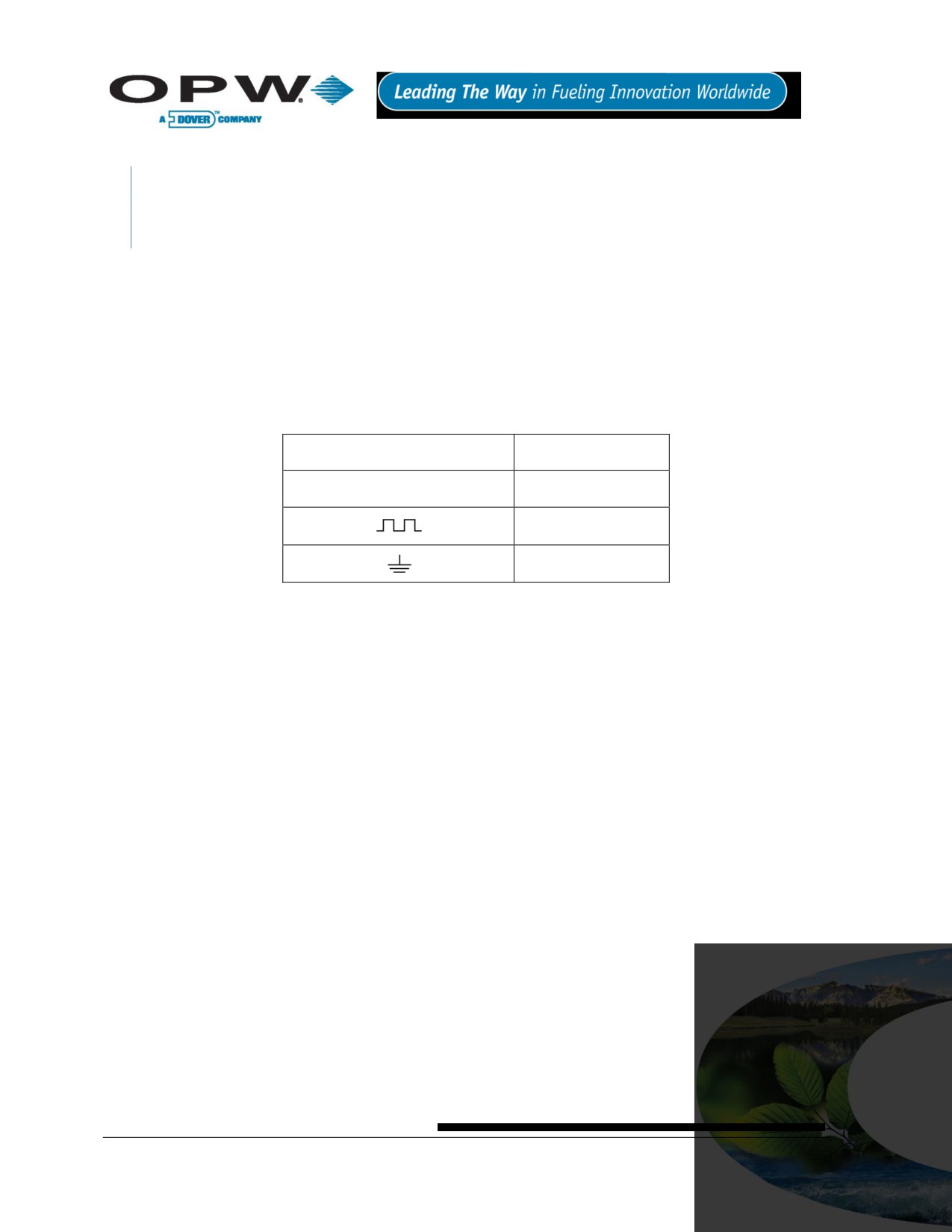

13.8 30-3221-1A, -1B Interstitial Level Sensors

13.8.1 About the 30-3221-1A, 1B

The two types of interstitial level sensor are used primarily in the interstitial

area of a double-walled tank. The sensor contains a float switch that

activates in the presence of a liquid. The 30-3221-1A is constructed from a

chemical-resistant non-metallic material and the B30-3221-1B is

constructed from brass.

It can also be used in sumps, dispenser pans and other locations where

the presence of a liquid could indicate that a leak has occurred. In

combination with a vapor sensor, this sensor can be used to monitor wet

wells to ensure that a liquid is normally present. In the event of a break in

Figure 13-13 Part # 30-3221-1B

the cable the system will activate the alarm.

13.8.2 Specifications

To ensure safe operating conditions, the sensor has been designed to

connect to OPW Fuel Management Systems only.

Figure 13-14 Part # 30-3221-1A

Operating Temperature

-20°C to 50°C (-4°F to 122°F)

Dimensions 30-3221-1A

3.4 cm (1.3 in) dia x

10 cm (3.9 in) long

Dimensions 30-3221-1B

3.5 cm (1.4 in) dia x

9.0 cm (3.5 in) long

Cable

4.5 m (15 ft) gas & oil-resistant

Page 58 of 123

13.8.3 Installing the 30-3221-1A, -1B

If monitoring a normally dry well, use a meter to orient the float so the sensor is in the closed state with

NO liquid present (float in lower position). If monitoring a normally wet well, use a meter to orient the

float so that it is in the closed state WITH liquid present (float in upper position).

This sensor requires ONE Interface Module position.

Review Figure 13-15 on page 60.

Use Table 13-7 below to connect the sensor to the Controller I.S. Interface Module terminals.

Use the supplied cable gland and silicone wire nuts.

Install seal-offs at both ends of the conduit run.

13.8.4 Connections

Table 13-7 Interstitial Level Sensor Wiring

I.S. Interface Module Position

Sensor Wire

+12

Red

Black

No Connection

Page 59 of 123

13.8.5 Typical Interstitial Level Sensor Installation

Figure 13-15 Interstitial Level Sensor Installation

13.8.6 SiteSentinel® iTouch™ Controller Setup for Interstitial Level Sensor

1. Configure the barrier position to be a generic sensor (or if using SiteConnect™, choose the

appropriate icon) and install that position.

2. Set the lower alarm threshold to 2.5 volts and set the upper alarm threshold to 5.0 volts (disables

upper threshold).

If monitoring a normally wet well, the lower threshold will indicate that the liquid is too low.

If monitoring a normally dry well, the lower threshold indicates that liquid is too high.

3. Program the alarms associated with the lower threshold that you wish to activate if the sensor detects

hydrocarbon liquid.

Page 60 of 123

13.8.7 Testing the Float Sensor

When working in the hazardous area use caution to avoid a hazardous situation.

When testing the sensor, work in a well-ventilated area with no hot surfaces or open flames.

If Sensor Installed in a Normally DRY Well

Place the float in the UPPER position - this should trigger an alarm in the controller.

Return the float to the LOWER position - the alarm should end.

If Sensor Installed in a Normally WET Well