Mazda Training manual - part 240

4 – VALVE TRAIN

45

Piston Engine Fundamentals

TC010-05-01S

The cylinder head includes spark plug mounting holes, valve ports and

seats, and coolant and oil passages.

Sealing

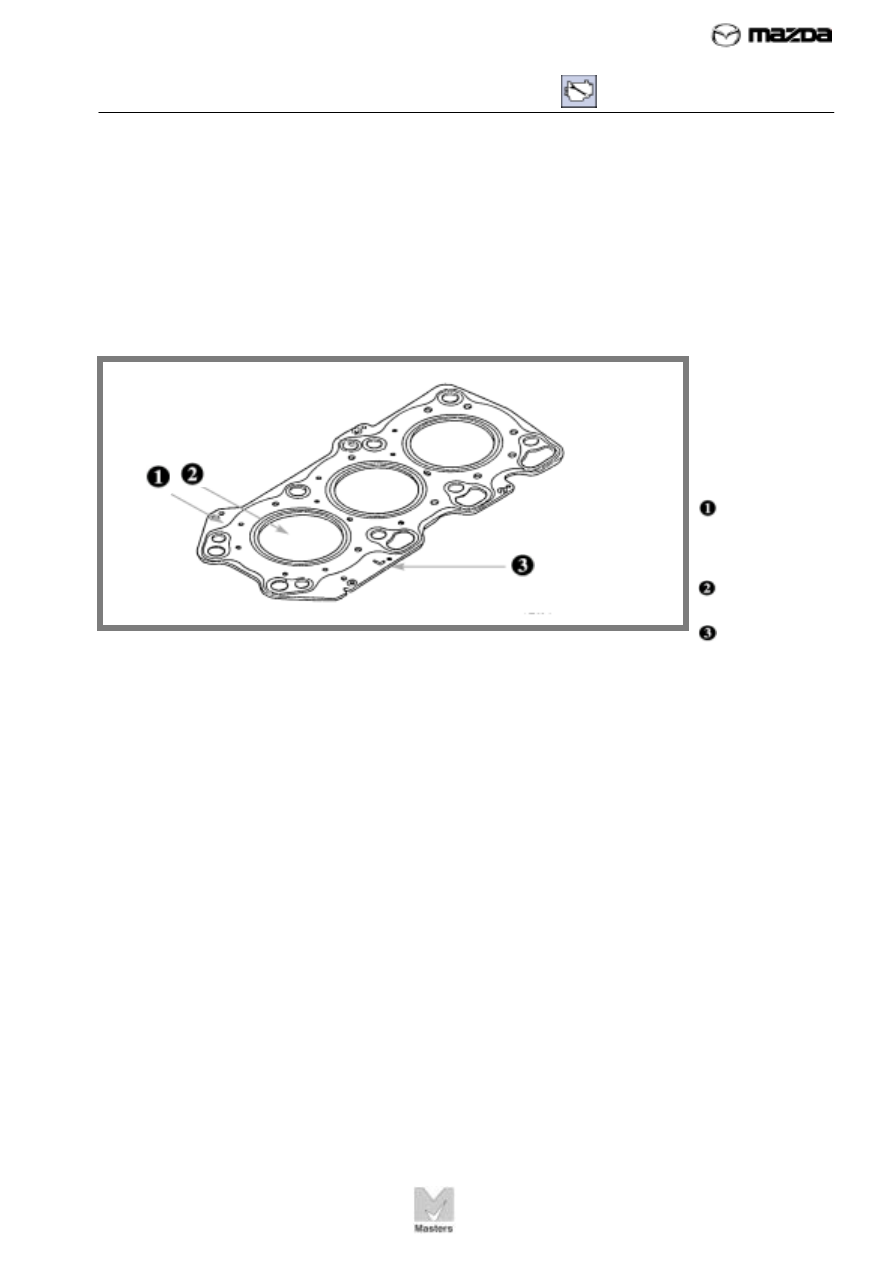

The cylinder head gasket, shown in Figure 30, seals the combustion

chambers. The gasket is usually made of steel coated with a softer sealing

material.

Because this seal is so important to engine operation, the head gasket

must be replaced whenever the cylinder head is removed and replaced. In

addition, the sequence and procedure for tightening the cylinder

head bolts is critical to good sealing.

FIGURE 30. The

cylinder head

gasket seals the

combustion

chambers and

coolant

passages.

Left cylinder

Head gasket

for V-6

engine

Cylinder

opening

Identifying

mark for left

cylinder head