Mazda Engine LF, L3. Manual - part 8

MECHANICAL

01–10–15

01–10

End Of Sie

VALVE SPRING INSPECTION

E5U011012125E01

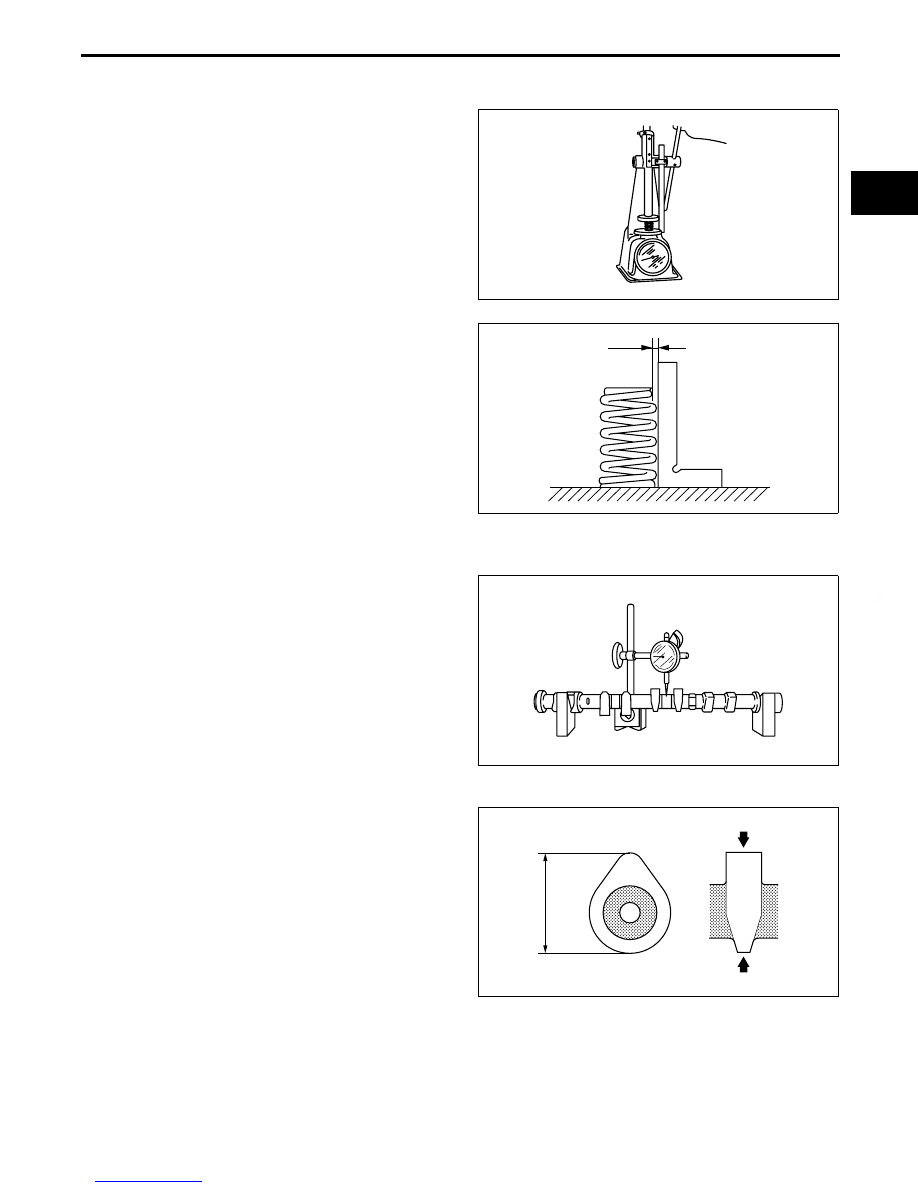

1. Apply pressing force to the pressure spring and inspect the spring height.

• If it is less than the specification, replace the

valve spring.

Valve spring pressing force

390 N {39.76 kgf, 87.67 lbf}

Valve spring standard height H

28.68 mm {1.129 in}

2. Measure the out-of-square of the valve spring,

using a square, as shown in the figure.

(1) Rotate the valve spring one full turn and

measure "A" at the point where the gap is the

largest.

• If it exceeds the specification, replace the

valve spring.

Valve spring out-of-square (Maximum)

1.95 mm {0.0767 in}

End Of Sie

CAMSHAFT INSPECTION

E5U011012420E01

1. Set the No.1 and No.5 journals on V-blocks.

2. Measure the camshaft runout.

• If it exceeds the specification, replace the

camshaft.

Maximum runout (Maximum)

0.03 mm {0.0012 in}

3. Measure the cam lobe height at the two points as

shown in the figure.

• If it is less than the specification, replace the

camshaft.

Camshaft standard height (mm {in})

With variable valve timing mechanism

IN: 42.44 {1.671}

EX: 41.18 {1.621}

Without variable valve timing mechanism

IN: 42.12 {1.659}

EX: 41.08 {1.618}

Camshaft minimum height (mm {in})

With variable valve timing mechanism

IN: 42.33 {1.666}

EX: 41.06 {1.616}

Without variable valve timing mechanism

IN: 42.01 {1.653}

EX: 40.96 {1.612}

ADJ2224E028

A

UPPER

LOWER

B3E0110E073

B3E0110E074

B3E0110E076