Mazda engine L8, LF, L3. Manual - part 11

B–24

ENGINE

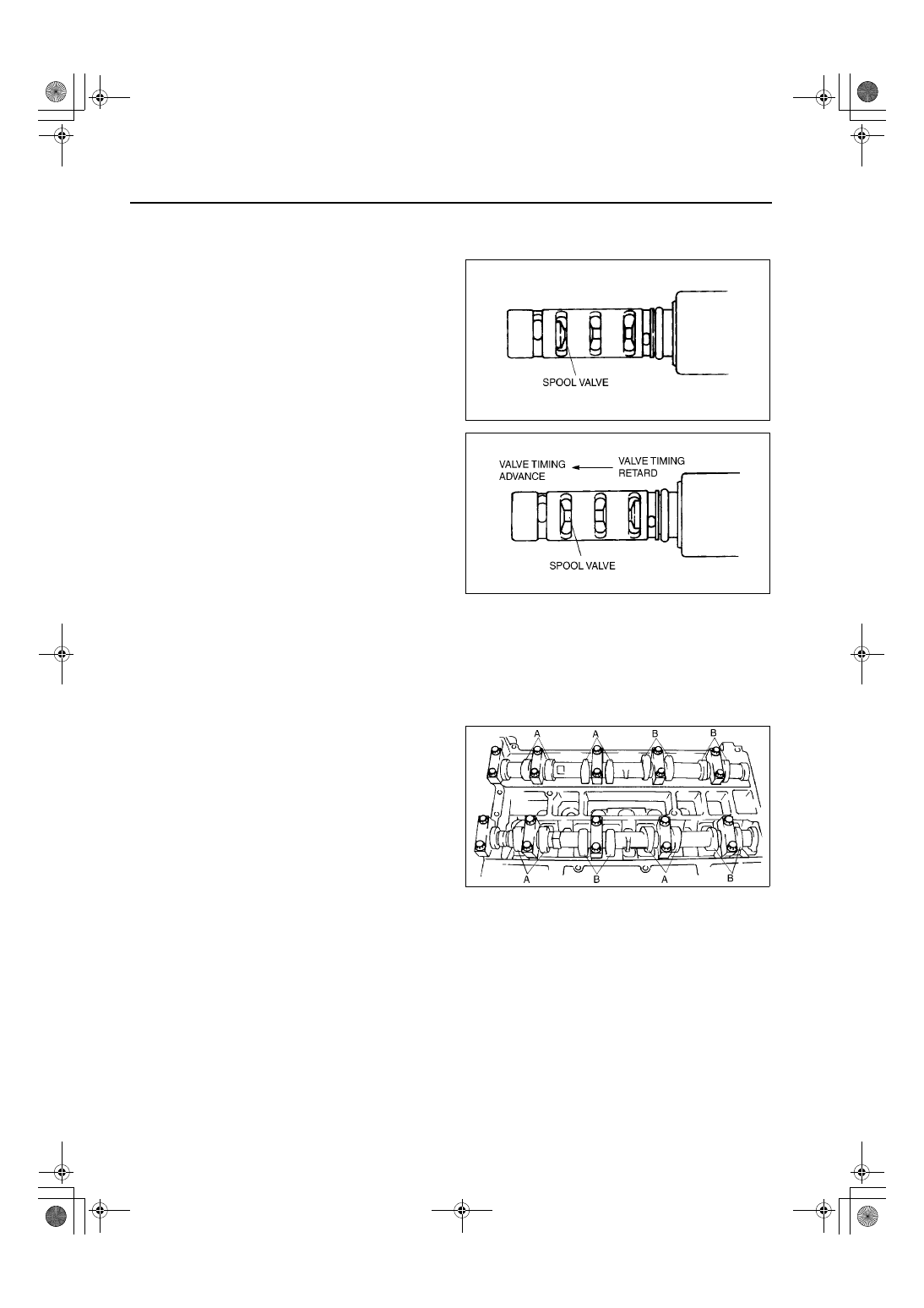

Spool valve operation inspection

1. Disconnect the negative battery cable.

2. Remove the oil control valve (OCV).

3. Verify that the spool valve in the oil control valve

(OCV) is in the maximum valve timing retard

position as indicated in the figure.

•

If not as specified, replace the oil control valve

(OCV).

4. Verify that the battery is fully charged.

•

If not as specified, recharge the battery.

5. Apply battery positive voltage between the oil

control valve (OCV) terminals and verify that the

spool valve operates and moves to the maximum

valve timing advance position.

•

If not as specified, replace the oil control valve

(OCV).

Note

•

When applying battery positive voltage

between the oil control valve (OCV)

terminals, the connection can be either of

the following:

— Positive battery cable to terminal A,

negative battery cable to terminal B

— Positive battery cable to terminal B, negative battery cable to terminal A

6. Stop applying battery positive voltage and verify that the spool valve returns to the maximum valve timing

retard position.

•

If not as specified, replace the oil control valve (OCV).

End Of Sie

VALVE CLEARANCE INSPECTION

A6E242412111E02

1. Measure the valve clearance as follows.

(1) Turn the crankshaft clockwise so that the

No.1 piston is at TDC of the compression

stroke.

(2) Measure the valve clearance at A in the

figure.

•

If the valve clearance exceeds the space

the tappet. (See

Note

•

Make sure to note the measured values for

choosing the suitable replacement tappets.

Standard [Engine cold]

IN: 0.22—0.28 mm {0.0087—0.0110 in} (0.25

±±±±

0.03 mm {0.0098

±±±±

0.0011 in})

EX: 0.27—0.33 mm {0.0106—0.0130 in} (0.30

±±±±

0.03 mm {0.0118

±±±±

0.0011 in})

(3) Turn the crankshaft 360

°°°°

clockwise so that the No.4 piston is at TDC of the compression stroke.

(4) Measure the valve clearance at B in the figure.

•

If the valve clearance exceeds the standard, replace the tappet. (See

Note

•

Make sure to note the measured values for choosing the suitable replacement tappets.

Standard [Engine cold]

IN: 0.22—0.28 mm {0.0087—0.0110 in} (0.25

±±±±

0.03 mm {0.0098

±±±±

0.0011 in})

EX: 0.27—0.33 mm {0.0106—0.0130 in} (0.30

±±±±

0.03 mm {0.0118

±±±±

0.0011 in})

AME2226W003

AME2226W004

AME2212W001