Mazda RX7. Manual - part 60

DRIVE AXLE

Article Text (p. 2)

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Sunday, August 26, 2001 06:34PM

AXLE SHAFTS & BEARINGS

Removal

1) Raise and support vehicle. Remove wheel. Remove brake

drum and brake shoes. Disconnect and plug hydraulic line from wheel

cylinder. Disconnect parking brake cable.

2) From inboard side of backing plate, remove 4 nuts from

axle housing through bolts. Pull drive axle, backing plate, bearing

housing (Pickups) and shims (if equipped) from axle housing with

drive axle puller (49 0223 630B). Remove oil seal from axle housing.

3) On Pickup models, flatten locking tabs of lock washer.

Loosen lock nut with spanner wrench. Remove lock nut and washer.

4) Using bearing pullers (49 8531 746 & 49 0259 747), remove

bearing and housing assembly from drive axle. Remove backing plate.

Remove bearing and oil seal from housing.

Installation

1) Install backing plate and spacer on shaft with chamfered

edge of spacer must face drive axle flange. Using bearing attachment,

(49 0259 748) press bearing onto shaft until seated. Press new

bearing collar onto shaft without any lubricant.

CAUTION: Do not press bearing and collar onto shaft at the same time.

If bearing collar is installed with less than 2.7 tons

pressure (2,451 kg), replace bearing collar.

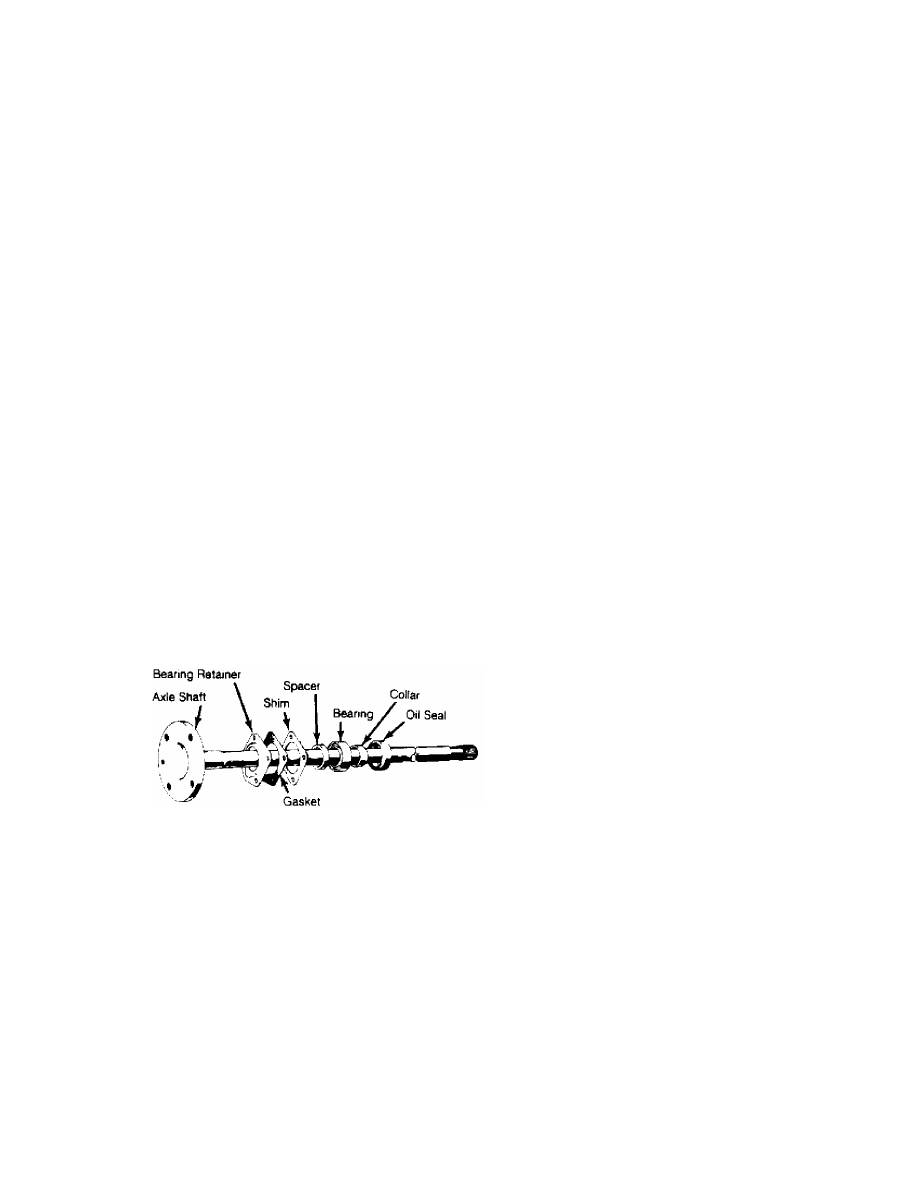

Fig. 2: Exploded View of Axle Shaft Assembly

for All Models Except Pickups

Chamfered edge of spacer must face drive axle flange.

2) Apply a light coat of grease to oil seal and install oil

seal in housing. Temporarily mount drive axle and backing plate on

axle housing with mounting nuts.

3) Install dial indicator on backing plate and check drive

axle end play. End play should be .002-.006" (.05-.15 mm) on Pickups

and 0-.004" (0-.1 mm) on all other models.

4) On Pickup models only, if both drive axles were removed,

the end play of each shaft must be measured separately. The end play

for first drive axle installed should be .026-.033" (.65-.85 mm).

5) The end play for the second drive axle installed should

be set to normal end play clearance of .002-.006" (.05-.15 mm).

6) After installing correct shim pack, install and tighten

all attaching bolts and nuts. Install brake shoes and drum. Connect

hydraulic lines to wheel cylinders, adjust brakes and bleed hydraulic