Mazda CX 7. Manual - part 435

INSTRUMENTATION/DRIVER INFO.

09-22–9

09-22

Check code 23

Check code 25

6

Inspect the wiring harness and connector between instrument cluster and fuel gauge sender unit.

• If there is any malfunction, repair or replace the wiring harness or connector.

• If there is no malfunction, replace the instrument cluster.

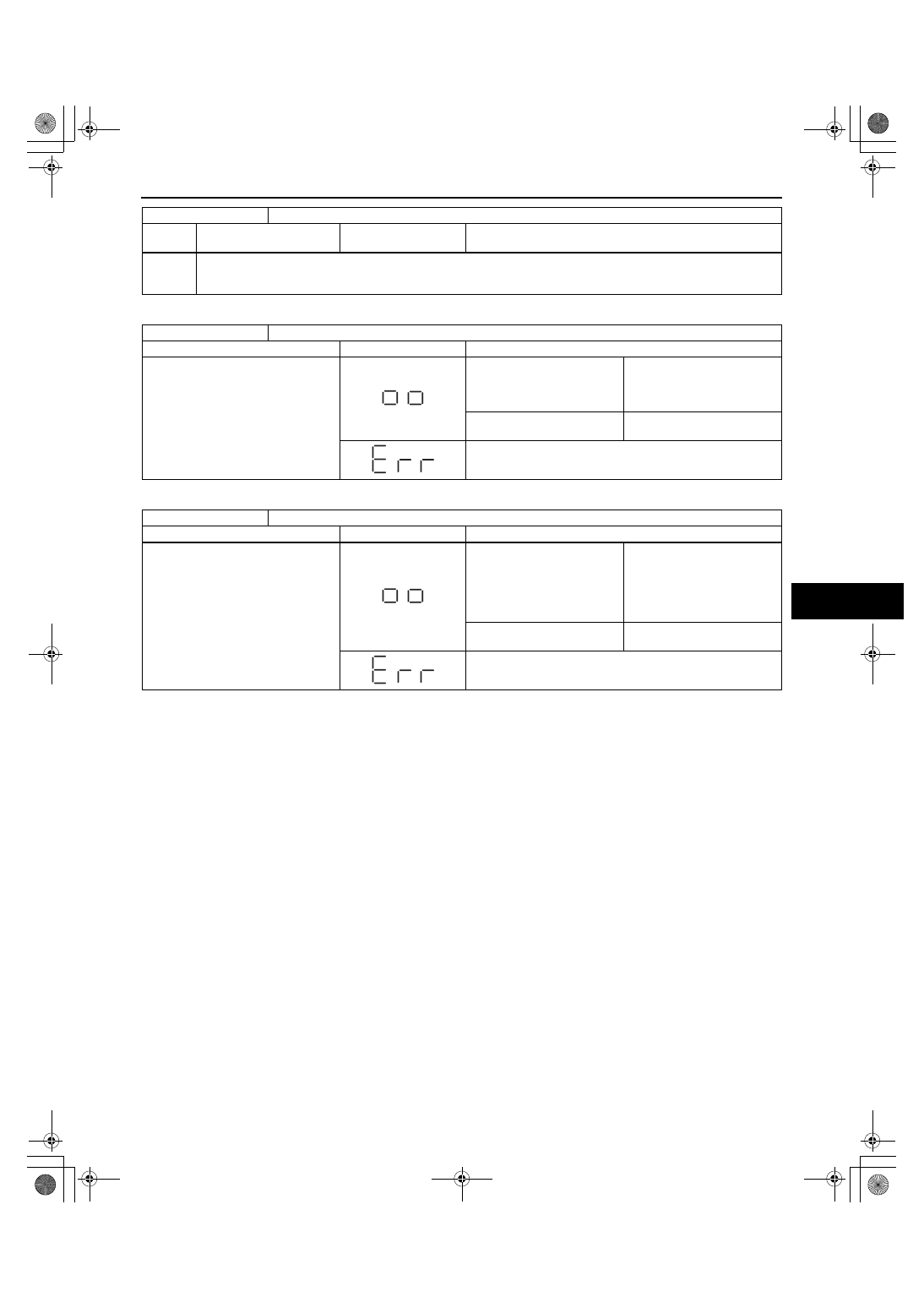

Check code 23

Fuel gauge operation signal

INSPECTION CONDITION

DISPLAY

ACTION

After selecting check code 23, wait

approx. 2 s.

The fuel gauge indicates

status in the following order

approx. every 2 s.

• F → 1/2 → E → F (fixed)

The fuel gauge is normal.

Except above

Replace the instrument

cluster.

Replace the instrument cluster.

Check code 25

Water temperature gauge operation signal

INSPECTION CONDITION

DISPLAY

ACTION

After selecting check code 25, wait

approx. 2 s.

The water temperature gauge

indicates status in the

following order approx. every

2 s.

• H → Center → C → H

(fixed)

The water temperature gauge

is normal.

Except above

Replace the instrument

cluster.

Replace the instrument cluster.

Check code 22

Fuel level signal

STEP

INSPECTION

CONDITION

DISPLAY

ACTION

1871-1U-06B(09-22).fm 9 ページ 2006年3月15日 水曜日 午後12時56分