Mazda CX 7. Manual - part 228

ON-BOARD DIAGNOSTIC [AW6A-EL, AW6AX-EL]

05-02–21

05-02

Diagnostic procedure

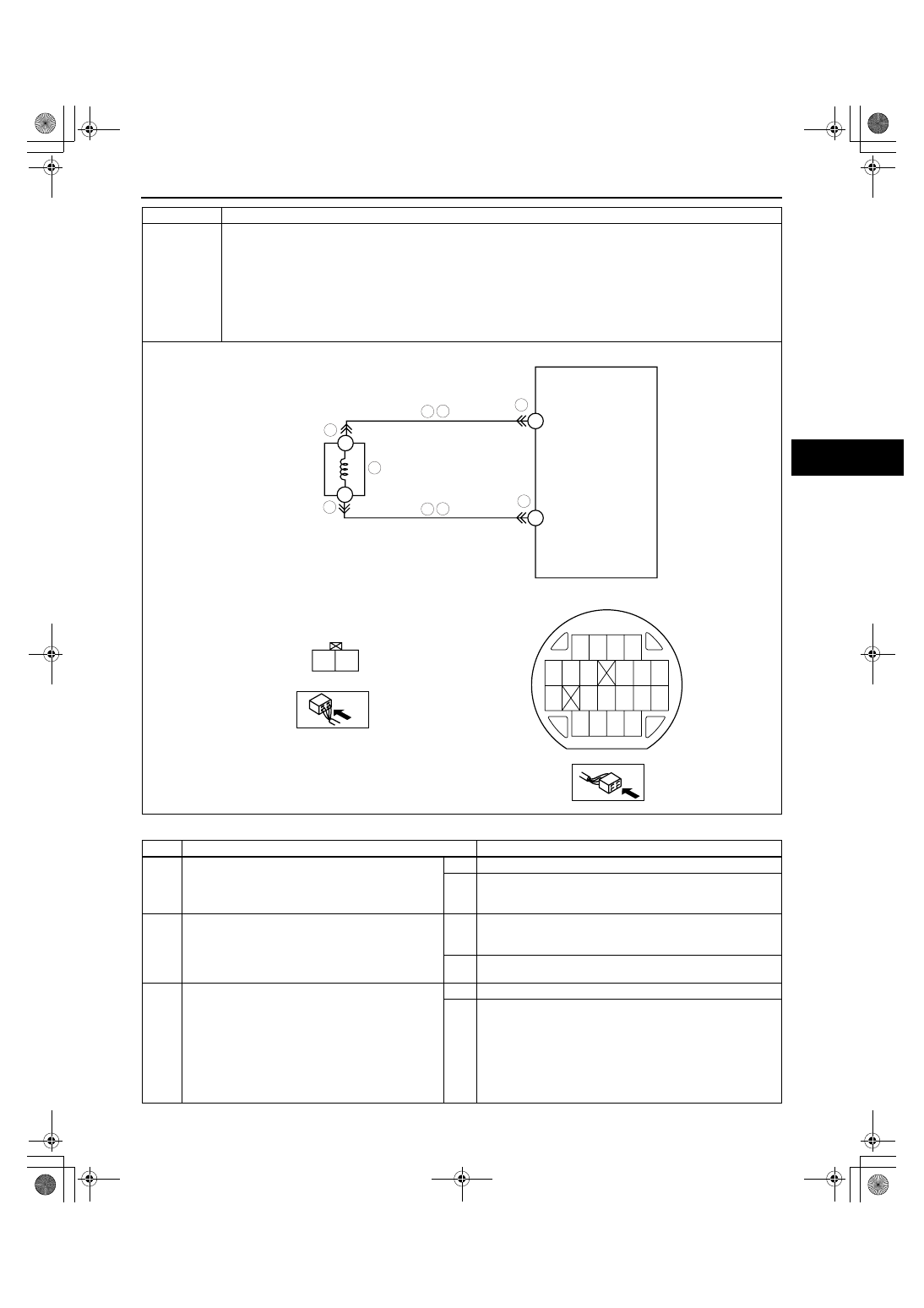

POSSIBLE

CAUSE

• VSS malfunction

• Open circuit between VSS terminal B and TCM terminal B19

• Open circuit between VSS terminal A and TCM terminal B20

• Short to ground in wiring harness between VSS terminal B and TCM terminal B19

• Short to ground in wiring harness between VSS terminal A and TCM terminal B20

• Short to power in wiring harness between VSS terminal B and TCM terminal B19

• Short to power in wiring harness between VSS terminal A and TCM terminal B20

• Damaged connector between VSS and TCM

• TCM malfunction

STEP

INSPECTION

ACTION

1

VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

• Has the FREEZE FRAME DATA been

recorded?

Yes

Go to the next step.

No

Record the FREEZE FRAME DATA on the repair order,

then go to the next step.

2

VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

• Verify related Service Bulletins and/or on-line

repair information availability.

• Is any related repair information available?

Yes

Perform repair or diagnosis according to the available

repair information.

• If the vehicle is not repaired, go to the next step.

No

Go to the next step.

3

INSPECT TERMINAL COUPLE COMPONENT

FOR POOR CONNECTION

• Turn the ignition switch to the LOCK position.

• Remove the TCM.

(See 05-17-25 TCM REMOVAL/

INSTALLATION[AW6A-EL, AW6AX-EL].)

• Inspect for poor connection (such as damaged/

pulled-out pins, corrosion).

• Are terminals normal?

Yes

Go to the next step.

No

Replace the couple component, then go to Step 8.

DTC P0722

Vehicle speed sensor (VSS) circuit malfunction (open circuit/short circuit)

B

A

B19

B20

A

B

VSS

VSS WIRING HARNESS-SIDE CONNECTOR

7

6

3

4

5

5

3

7

6

TCM

COUPLE COMPONENT CONNECTOR

COUPLE COMPONENT

B20

B19

(+)

(-)

1871-1U-06B(05-02).fm 21 ページ 2006年3月15日 水曜日 午前11時18分