Mazda CX 7. Manual - part 211

CONVENTIONAL BRAKE SYSTEM

04-11–15

04-11

The disc plate is deformed by heat.

Repeated panic braking may raise the temperature in some portions of disc plate by approx. 1,000

°C {1,832 °F}.

This results in deformed disc plate.

Due to corrosion, the thickness and friction coefficient of disc plate change.

If a vehicle is parked under damp conditions for a long time, corrosion occurs on the friction surface of disc plate.

The thickness of corrosion is uneven and sometimes appears like a wave pattern, which changes the friction

coefficient and causes a reaction force.

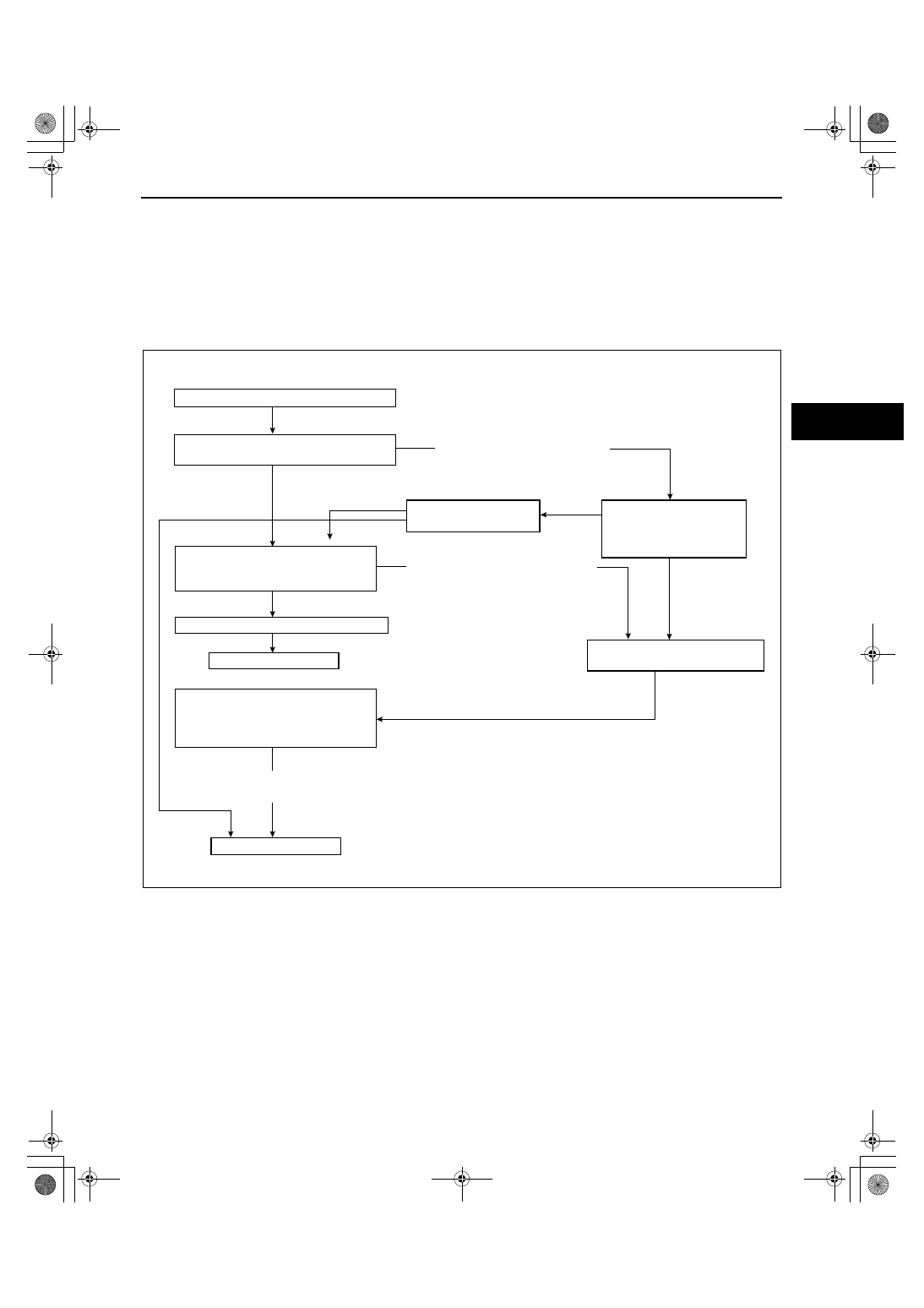

Inspection and repair procedure

Lateral runout inspection

1. To secure the disc plate and the hub, tighten the hub nuts upside down or insert a washer (thickness 10 mm

{0.39 in} with an inner diameter more than 12 mm {0.47 in}) between the hub bolt and the hub nut.

Note

• The component parts of the SST (49 B017 001 or 49 G019 003) can be used as a suitable washer.

2. After tightening all the hub nuts to the same torque, put the dial gauge on the friction surface of disc plate 10

mm {0.39 in} from the disc plate edge.

3. Rotate the disc plate one time and measure the runout.

Front disc plate runout limit

0.05 mm {0.002 in}

Occurs

Does not

occur

Confirm customer

,

s complaint

Less than

0.05 mm

{0.002 in}

Less than 0.015 mm {0.0005 in}

On-the-car type lathe (less than

0.015 mm {0.0005 in}).

More than 0.015 mm {0.0005 in}

More than 0.05 mm {0.002 in}

More than

0.05 mm

{0.002 in}

Less than

0.05 mm

{0.002 in}

Perform lateral runout inspection.

(Refer to Lateral Runout Inspection.)

Verify whether brake

judder occurs or not.

Machine the disc plate using

on-the-car type lathe.

Remove disc plate and

reinstall in other phase.

Perform lateral runout

inspection again.

Perform thickness variation

inspection (Refer to the

following.)

Secure the disc plate by

tightening all hub nuts to the

same torque, and measure lateral

runout.

Work is completed.

Confirm customer's complaint again.

Work is completed.

acxuuw00001079

1871-1U-06B(04-11).fm 15 ページ 2006年3月15日 水曜日 午前11時13分