Mazda CX 7. Manual - part 160

WHEEL AND TIRES

02-12–1

02-12

2007 Mazda CX-7 Workshop Manual (1871–1U–06B)

Revised 3/2007 (Ref. No. R051/07)

02-12

WHEEL AND TIRES

WHEEL AND TIRE SPECIFICATION . . . 02-12–1

WHEEL BALANCE ADJUSTMENT . . . . 02-12–2

Adhesive-type Balance Weight

(Outer). . . . . . . . . . . . . . . . . . . . . . . . 02-12–2

Knock-type Balance Weight (Inner) . . . 02-12–3

Remaining Amount of Unbalance

Confirmation. . . . . . . . . . . . . . . . . . . . 02-12–3

TIRE PRESSURE ADJUSTMENT

(WITH TPMS) . . . . . . . . . . . . . . . . . . . . 02-12–3

WHEEL UNIT ID REGISTRATION . . . . . . 02-12–4

Using M-MDS . . . . . . . . . . . . . . . . . . . . 02-12–4

Without Using M-MDS. . . . . . . . . . . . . . 02-12–4

WHEEL UNIT

REMOVAL/INSTALLATION . . . . . . . . . . 02-12–4

Valve Core Removal Note . . . . . . . . . . . 02-12–5

Wheel Unit Removal Note . . . . . . . . . . . 02-12–5

Wheel Unit Installation Note . . . . . . . . . 02-12–6

End of Toc

WM: WHEELS AND TIRES

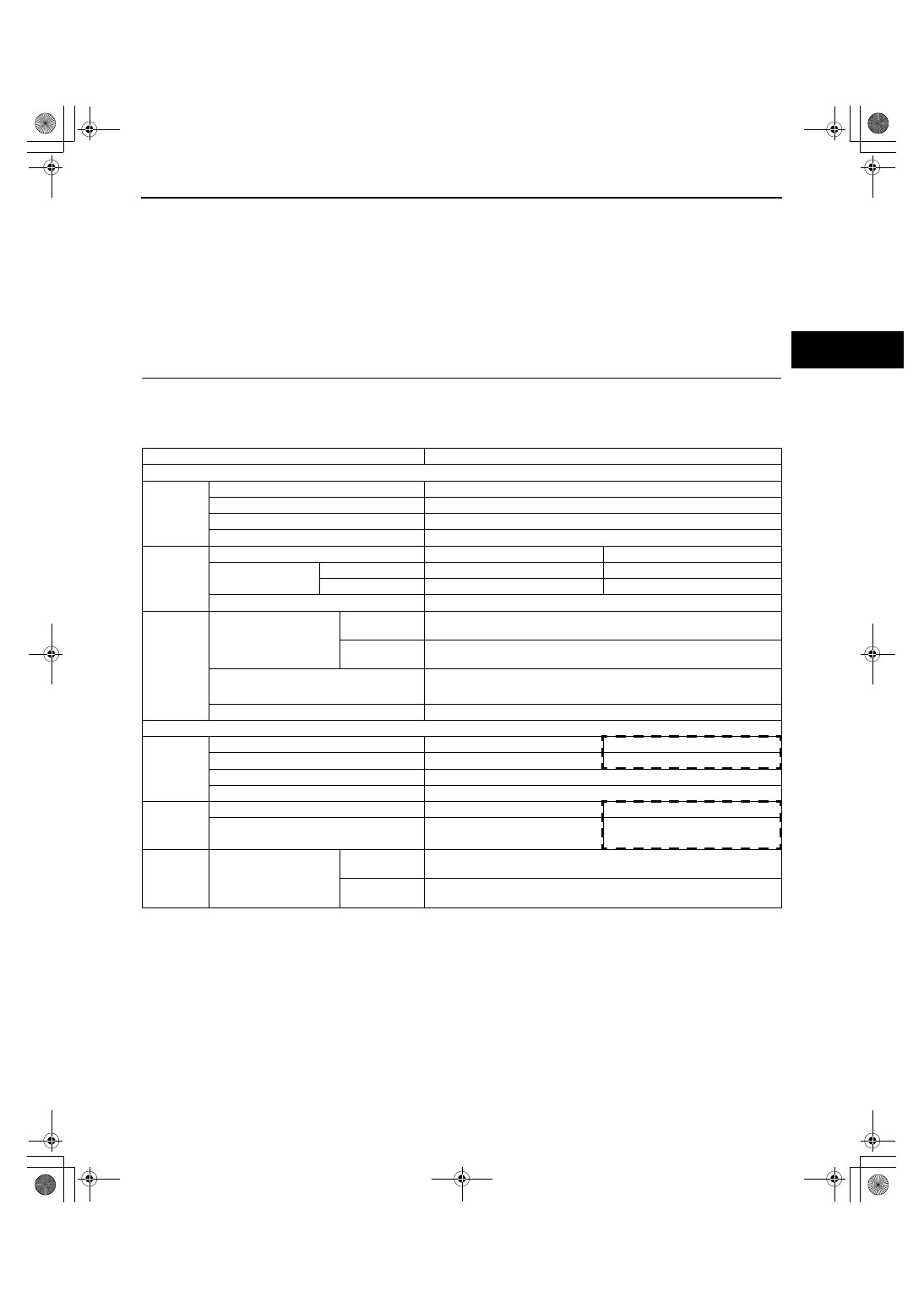

WHEEL AND TIRE SPECIFICATION

id021200800100

Wheel and tire

*

1

: Total weight exceeds 160 g {5.65 oz}.

*

2

: One balance weight: 60 g {2.12 oz} max. If the total weight exceeds 100 g {3.53 oz} on one side, rebalance

after moving the tire around on the rim. Do not use three or more balance weights.

End Of Sie

Item

Specification

Standard tire and wheel

Wheel

Size

18

× 7 1/2J

Offset

(mm {in})

50 {1.97}

Pitch circle diameter

(mm {in})

114.3 {4.50}

Material

Aluminum alloy

Tire

Size

P235/60R18 102H

235/60R18 103H (Mexico spec.)

Air pressure

(kPa {kgf/cm

2

, psi})

Front

220 {2.2, 32}

230 {2.3, 34} (Mexico spec.)

Rear

220 {2.2, 32}

230 {2.3, 34} (Mexico spec.)

Remaining tread

(mm {in})

1.6 {0.06}

Wheel and

tire

Wheel and tire runout

Radial

direction

1.5 {0.06} max.

(mm {in}) Lateral

direction

2.0 {0.08} max.

Wheel imbalance

(g {oz})

Adhesive-type*

1

: 10 {0.35} max.

Knock-type*

2

: 6 {0.21} max.

Tightening torque

(N·m {kgf·m, ft·lbf})

88.2—117.6 {9.00—11.99, 65.06—86.73}

Temporary spare tire

Wheel

Size

18

× 4T

16

× 5J

Offset

(mm {in})

40 {1.57}

45 {1.77}

Pitch circle diameter

(mm {in})

114.3 {4.50}

Material

Steel

Tire

Size

T155/90D18 103M

205/80R16 100M

Air pressure

(kPa {kgf/cm

2

, psi})

420 {4.2, 60}

250 {2.5, 36}

Wheel and

tire

Wheel and tire runout

Radial

direction

2.0 {0.08} max.

(mm {in}) Lateral

direction

2.5 {0.10} max.