Mazda CX 7. Manual - part 134

CHARGING SYSTEM [L3 WITH TC]

01-17–7

01-17

9. Turn the following electrical loads on and verify that the current reading increases more than the minimum

value indicated below.

— If it is not as specified, go to the PCM and generator shearing inspection. (See 01-17-7 PCM and generator

shearing inspection.)

• Headlights (high-beam)

• Blower motor (HI)

• Rear window defroster

• Brake lights

Generator generated current minimum value

70 % of the nominal output current (nominal output current: 110 A)

[Ambient temp. 20

°C {68 °F}, voltage 13.0— 15.0 V, both engine and generator are hot]

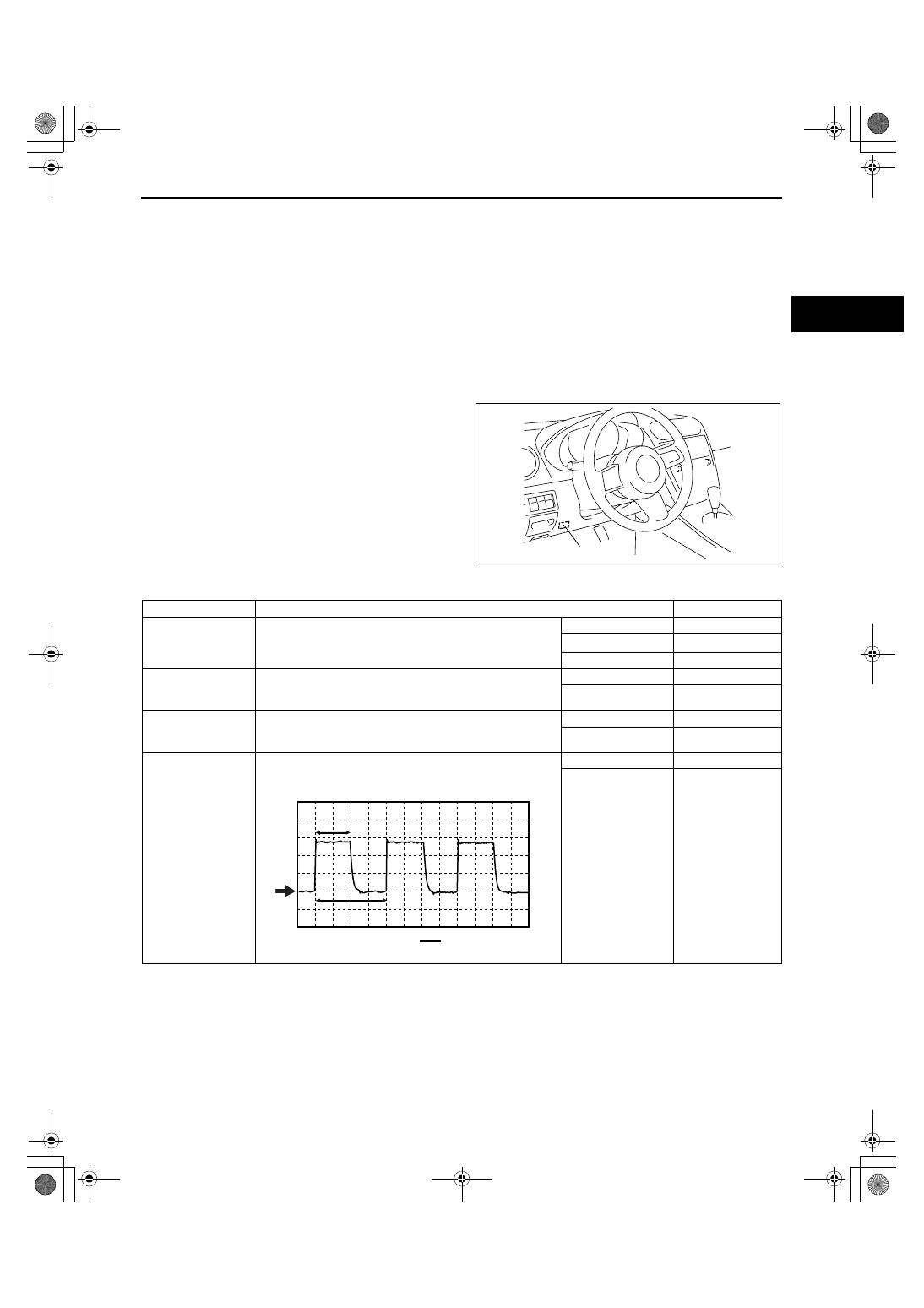

PCM and generator shearing inspection

1. Connect the M-MDS to the DLC-2.

2. Inspect as follows:

DLC-2

acxuuw00002019

Step

Inspection

Action

1

Measure the generator terminal B voltage when the

electrical loads

*1

are on and off.

15 V or more

Go to Step 2.

13— 15 V

Normal

*2

13 V or less

Go to Step 3.

2

Monitor the ALTT V PID using the M-MDS, or measure the

voltage of PCM terminal 2AJ using a tester. Is the voltage

between 13 and 15 V ?

Yes

Go to Step 4.

No

PCM input error.

3

Monitor the ALTT V PID using the M-MDS, or measure the

voltage of PCM terminal 2AJ using a tester. Is the voltage

between 13 and 15 V ?

Yes

Go to Step 5.

No

PCM input error.

4

Monitor the ALTF PID using the M-MDS, or calculate the

duty value of the PCM terminal 2AI using an oscilloscope.

Is the duty value 100 % ?

Yes

PCM input error.

No

PCM, generator, or

both are not

normal.

0V

A

B

B

A

x 100 (%) = DUTY (%)

1871-1U-06B(01-17).fm 7 ページ 2006年3月15日 水曜日 午前10時49分