Mazda CX 7. Manual - part 122

FUEL SYSTEM [L3 WITH TC]

01-14–9

01-14

16. Install in the reverse order of removal.

17. Complete the “AFTER REPAIR PROCEDURE”. (See01-14-4 AFTER REPAIR PROCEDURE[L3 WITH TC].)

Rivet Removal Note

Caution

• Be careful not to damage the fuel tank when removing the rivet. If the fuel tank is damaged, it may

cause fuel leakage.

Note

• The insulator is installed using rivets.

• When resin stalling the rivet, install the same rivet or M5 bolt and nut.

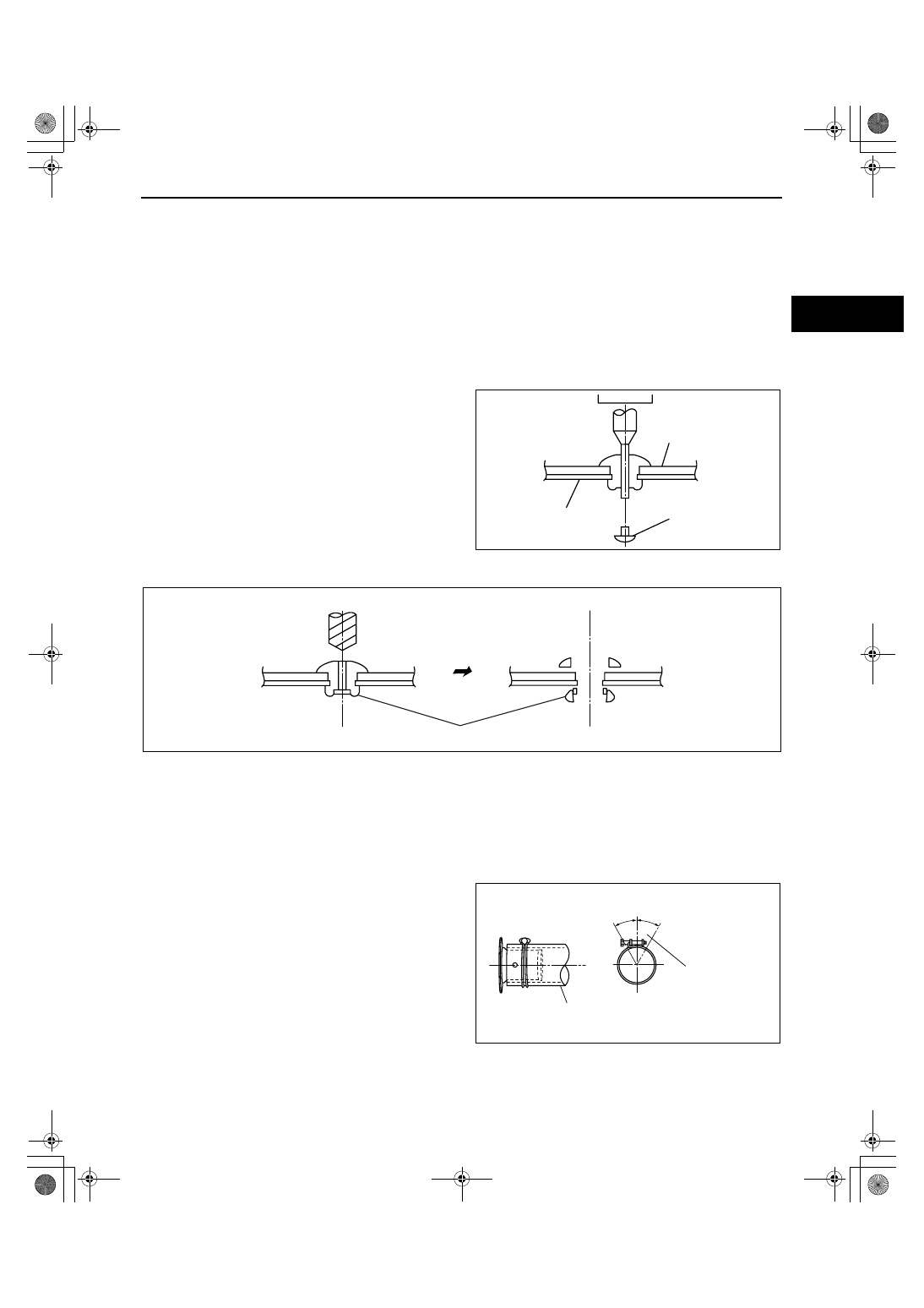

1. Push out the mandrel using a hammer and punch

(2—2.8 mm {0.08—0.11 in} diameter).

2. Remove the flange using a drill (5 mm {0.20 in} drill bit).

Fuel-filler Pipe Removal Note

1. Remove the rear tire (LH).

2. Remove the mudguard (LH).

3. Remove the air filter.

4. Remove the fuel-filler pipe.

Joint Hose Installation Note

1. Install the joint hose and clamp as shown in the

figure.

HAMMER

INSULATOR

FUEL TANK

MANDREL

acxuuw00000260

DRILL

FLANGE

acxuuw00000261

JOINT HOSE

CLAMP

TIGHTENING AREA

30

°

30

°

VIEW A

acxuuw00000265

1871-1U-06B(01-14).fm 9 ページ 2006年3月15日 水曜日 午前10時45分