Mazda CX 7. Manual - part 96

SYMPTOM TROUBLESHOOTING [L3 WITH TC]

01-03–81

01-03

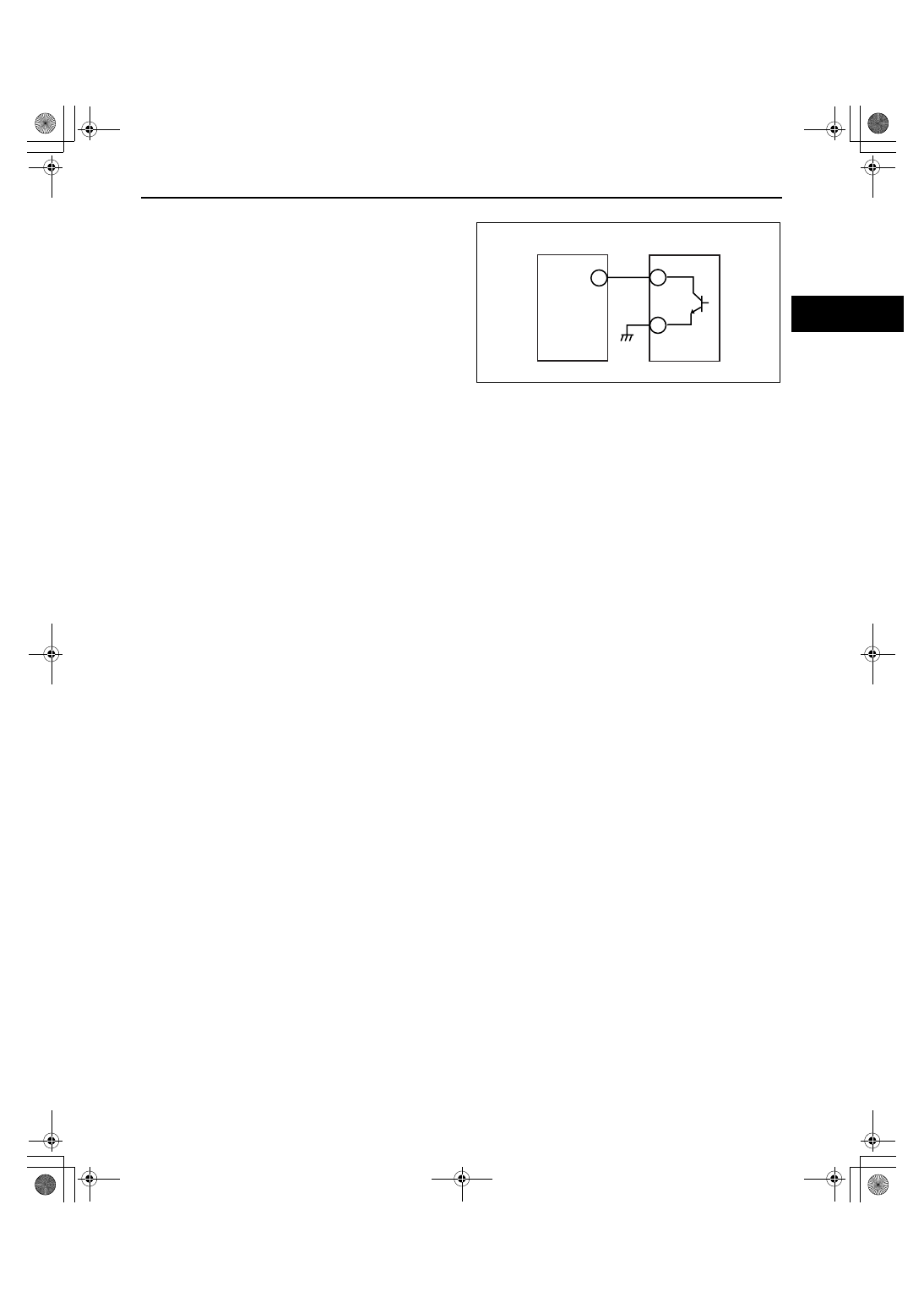

VSS

1. Measure the #1 PCM terminal voltage and confirm that it is at 0 V or 5 V when the ignition switch to the ON

position and the engine is idling.

• If it is at 0 V or 5 V, intermittent concern exists. (See01-03-76 INTERMITTENT CONCERN

TROUBLESHOOTING[L3 WITH TC].)

• If not, inspect the following points concerning the PCM connector.

• If there is no problem, inspect for the following:

— Female terminal opening is loose.

— Coupler (pin holder) damage

— Pin discoloration (blackness)

— Wiring harness/pin crimp is loose or disconnected.

2. Measure the #2 sensor terminal voltage and confirm that it is at 0 V or 5 V when the ignition switch to the ON

position and the engine is idling.

• If it is at 0 V or 5 V, intermittent concern exists. (See01-03-76 INTERMITTENT CONCERN

TROUBLESHOOTING[L3 WITH TC].)

• If not, inspect the following points concerning the sensor connector:

• If there is no problem, inspect for the following.

— Female terminal opening is loose.

— Coupler (pin holder) damage

— Pin discoloration (blackness)

— Wiring harness/pin crimp is loose or disconnected.

3. Confirm that the #3 terminal switch voltage is at 0 V.

• If it is at 0 V, inspect the sensor. If necessary, replace the sensor.

— If necessary, replace the sensor.

• If not, inspect for the following:

— Open circuit in wiring harness

— Female terminal opening is loose.

— Coupler (pin holder) damage

— Pin discoloration (blackness)

— Wiring harness/pin crimp is loose or disconnected.

Main Relay Operation Inspection

1. Verify that the main relay clicks when the ignition switch is turned to ON position and then off.

• If there is no operation sound, inspect the following:

— Main relay (See09-21-4 RELAY INSPECTION.)

— Wiring harness and connector between ignition switch and main relay terminal A.

— Wiring harness and connector between PCM terminal 1AT and main relay terminal B.

PCM

INPUT

1

3

2

acxuuw00002367

1871-1U-06B(01-03).fm 81 ページ 2006年3月15日 水曜日 午前10時36分