Mazda CX 7. Manual - part 68

ON-BOARD DIAGNOSTIC [L3 WITH TC]

01-02–227

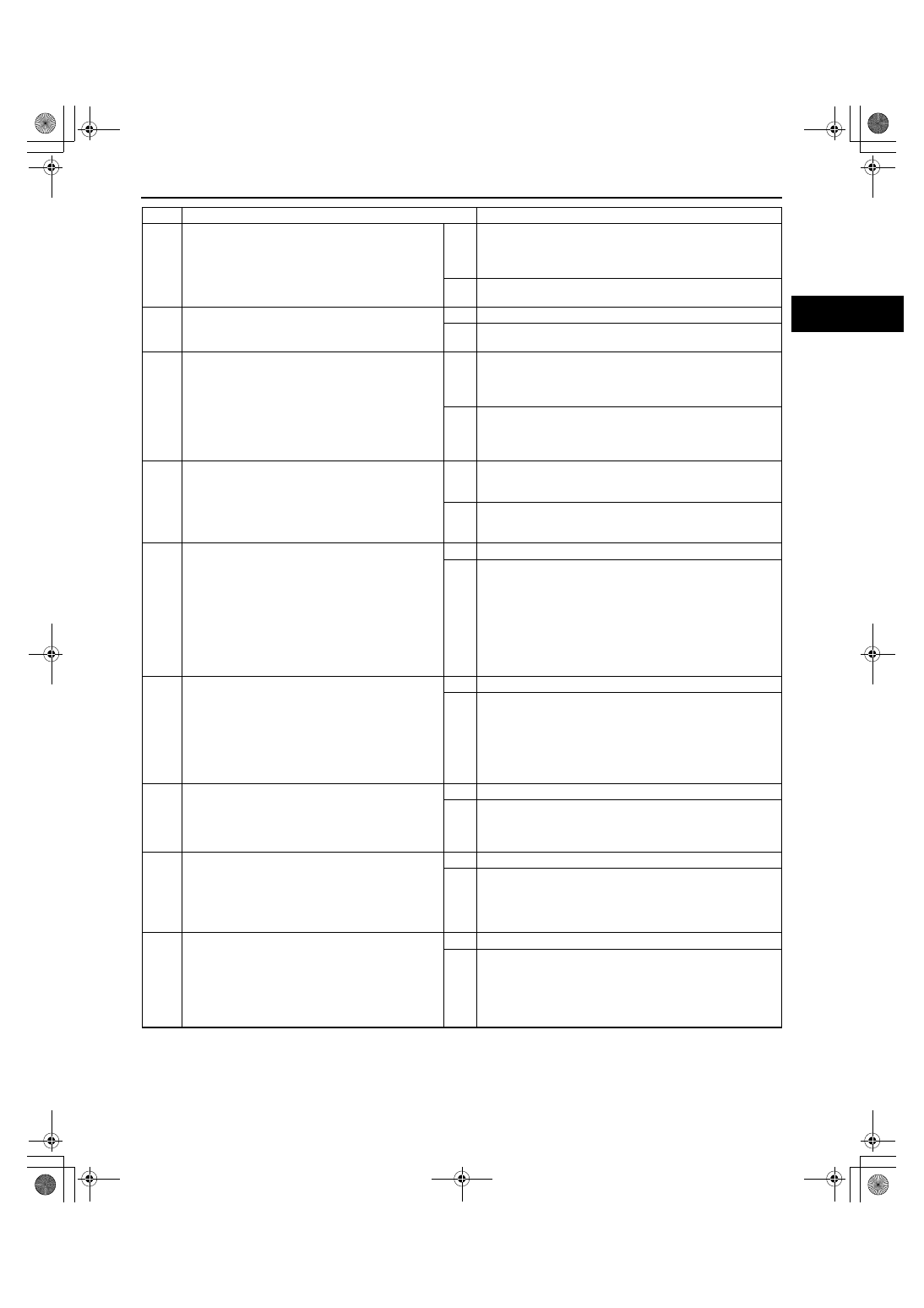

01-02

3

VERIFY RELATED PENDING CODE OR

STORED DTCS

• Turn the ignition switch to off, then to the ON

position (Engine off).

• Verify related pending code or stored DTCs.

• Are other DTCs present?

Yes

If misfire the DTC is present, go to Step 8.

If other DTCs is present, go to the applicable DTC

inspection.

(See01-02-13 DTC TABLE[L3 WITH TC].)

No

If driveability concern is present, go to Step 8.

If not, go to the next step.

4

IDENTIFY TRIGGER DTC FOR FREEZE FRAME

DATA

• Is DTC P2178 on FREEZE FRAME DATA?

Yes

Go to the next step.

No

Go to troubleshooting procedures for DTC on FREEZE

FRAME DATA.

5

VERIFY CURRENT INPUT SIGNAL STATUS

(IGNITION SWITCH TO THE ON POSITION/

IDLE)

• Access the APP1, APP2, ECT, MAF, TP and

VSS PIDs using the M-MDS.

• Is there any signal that is far out of specification

when the ignition switch is at the ON position

and engine runs?

Yes

Inspect the sensor and excessive resistance in related

wiring harnesses.

Repair or if necessary.

Then go to Step 19.

No

Go to the next step.

6

VERIFY CURRENT INPUT SIGNAL STATUS

UNDER TROUBLE CONDITION

• Inspect the same PIDs as Step 5 while

simulating FREEZE FRAME DATA condition.

• Is there any signal which causes drastic

changes?

Yes

Inspect the sensor and related wiring harnesses, repair or

replace it.

Then go to Step 19.

No

Go to the next step.

7

VERIFY CURRENT INPUT SIGNAL STATUS OF

FRONT HO2S

• Access the O2S11 for P2177 PID using the M-

MDS.

• Check the PID under following accelerator

pedal condition in NEUTRAL.

• Is the PID reading normal?

— –0.1— 0.1 A when idle

— Below 0.25 mA just after release of

accelerator pedal (lean condition)

Yes

Go to the next step.

No

Visually inspect for any gas leakage between the exhaust

manifold and the front HO2S.

Then go to Step 19.

8

VERIFY CURRENT INPUT SIGNAL STATUS OF

MAF SENSOR

• Connect the M-MDS to the DLC-2.

• Start the engine.

• Access the MAF PID.

• Verify that the MAF PID changes quickly

according to engine speed.

• Is the PID normal?

Yes

Go to the next step.

No

Replace the MAF/IAT sensor, then go to Step 19.

9

INSPECT PURGE SOLENOID OPERATION

• Perform the Purge Control System Inspection.

(See01-03-78 ENGINE CONTROL SYSTEM

OPERATION INSPECTION[L3 WITH TC].)

• Does the purge control system work properly?

Yes

Go to the next step.

No

Repair or replace the malfunctioning part according to

inspection result, then go to Step 19.

10

INSPECT PCV VALVE OPERATION

• Inspect the PCV valve operation.

(See01-16-14 POSITIVE CRANKCASE

VENTILATION (PCV) VALVE INSPECTION[L3

WITH TC].)

• Is the PCV valve normal?

Yes

Go to the next step.

No

Replace the PCV valve, then go to Step 19.

11

INSPECT VARIABLE SWIRL CONTROL

OPERATION

• Perform the Variable Swirl Control Operation

Inspection.

(See01-03-78 ENGINE CONTROL SYSTEM

OPERATION INSPECTION[L3 WITH TC].)

• Does the variable swirl control work properly?

Yes

Go to the next step.

No

Repair or replace the malfunctioning part according to

inspection result, then go to Step 19.

STEP

INSPECTION

ACTION

1871-1U-06B(01-02).fm 227 ページ 2006年3月15日 水曜日 午前10時32分