Mazda CX 7. Manual - part 2

GENERAL INFORMATION

00-00–3

00-00

HOW TO USE THIS MANUAL

id000000800100

Range of Topics

• This manual contains procedures for performing all required service operations. The procedures are divided

into the following five basic operations:

— Removal/Installation

— Disassembly/Assembly

— Replacement

— Inspection

— Adjustment

• Simple operations which can be performed easily just by looking at the vehicle (i.e., removal/installation of

parts, jacking, vehicle lifting, cleaning of parts, and visual inspection) have been omitted.

Service Procedure

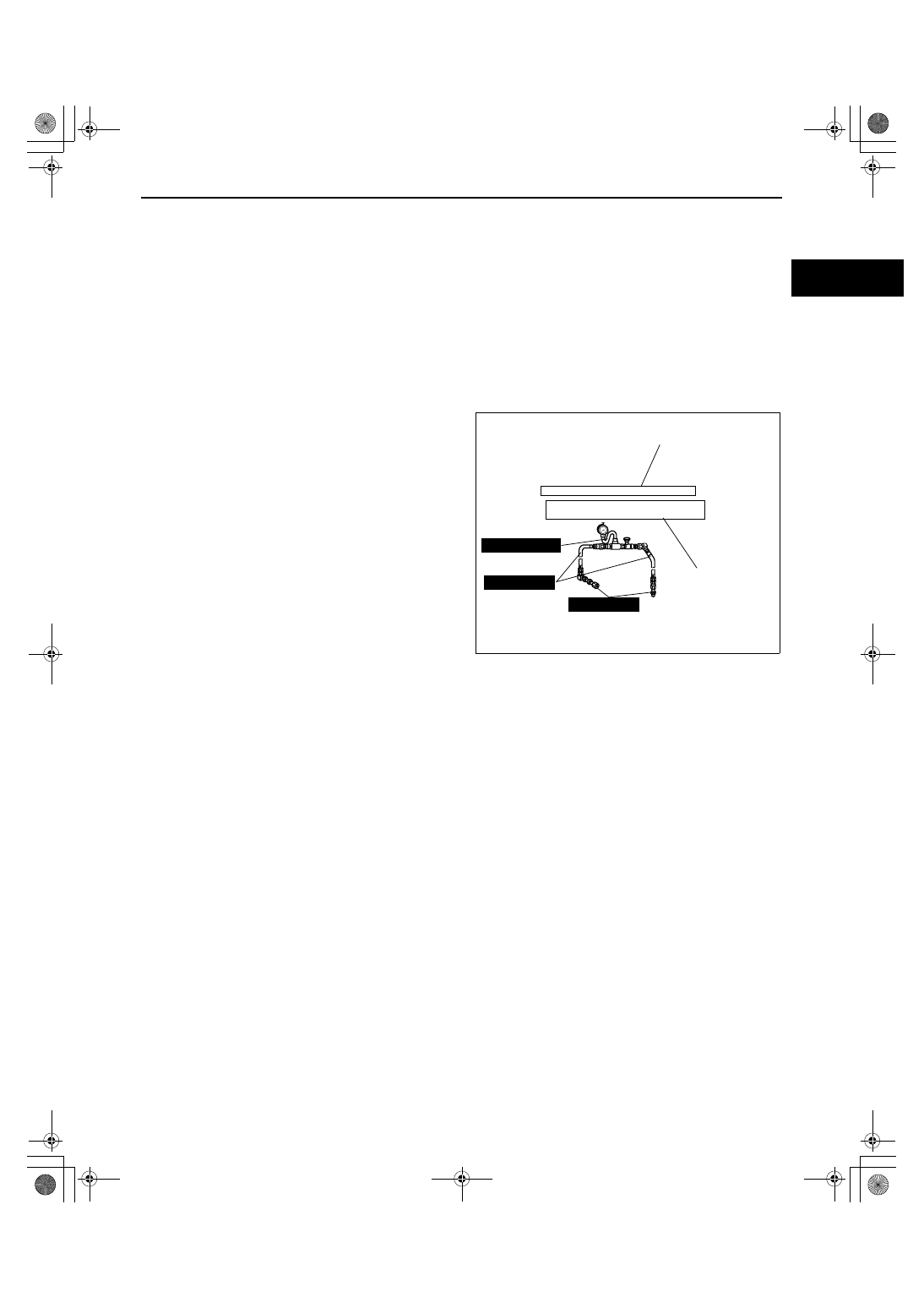

Inspection, adjustment

• Inspection and adjustment procedures are

divided into steps. Important points regarding the

location and contents of the procedures are

explained in detail and shown in the illustrations.

49 H002 671

49 H032 322

49 1232 670A

SHOWS PROCEDURE ORDER

FOR SERVICE

Fluid Pressure Inspection

1. Assemble the SSTs as shown in the figure.

Tightening torque

SHOWS TIGHTENING

TORQUE

SPECIFICATIONS

Caution

Connect the gauge set from under

the vehicle to prevent contact with

the drive belt and the cooling fan.

39—49 N·m {4.0—5.0 kgf·m, 29—36 ft·lbf}

acxuuw00000434