Mazda Protege 5. Manual - part 307

SYMPTOM TROUBLESHOOTING

09–03–7

09–03

End Of Sie

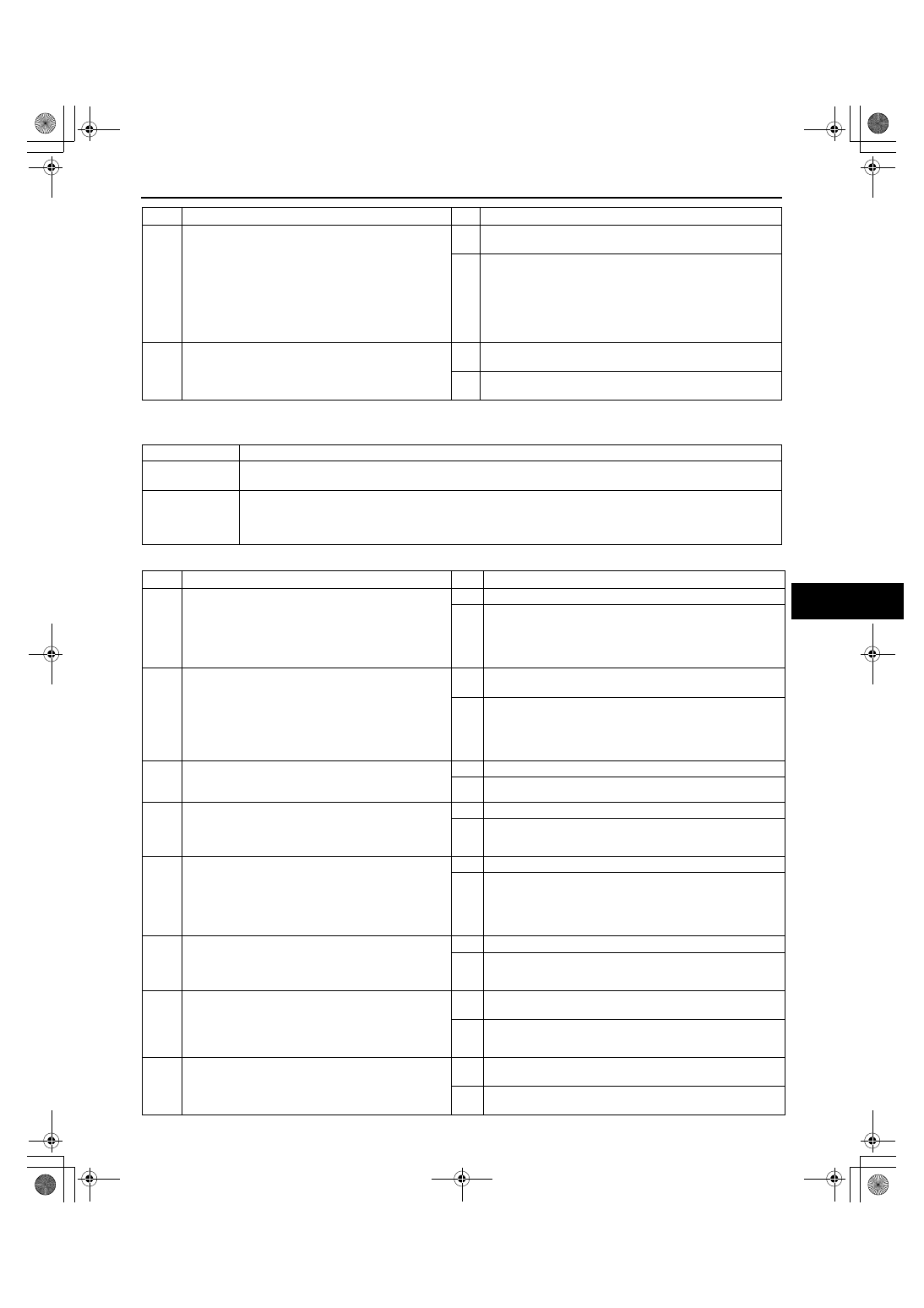

NO.3 TRANSMITTER ID CODE CANNOT BE REPROGRAMMED

A3U090369000W08

Diagnostic procedure

End Of Sie

7

INSPECT KEYLESS CONTROL MODULE OR

WIRING HARNESS (BETWEEN KEYLESS

CONTROL MODULE AND DOOR SWITCHES,

CARGO COMPARTMENT LIGHT SWITCH FOR

CONTINUITY)

•

Open the driver-side door.

•

Open the liftgate.

•

Is there continuity between keyless control

module connector terminal C, D and ground?

Yes Replace keyless control module and reprogram keyless

control module ID code, then go to next step.

No

Repair wiring harness between keyless control module

and door switches, cargo compartment light switch then go

to next step.

8

RECHECK MALFUNCTION SYMPTOM AFTER

REPAIR

•

Does keyless entry system operate properly?

Yes Troubleshooting completed.

Explain repairs to customer.

No

Recheck malfunction symptoms, then repeat from Step 1 if

malfunction recurs.

STEP

INSPECTION

ACTION

3

Transmitter ID code cannot be reprogrammed

DESCRIPTION

•

Malfunction in transmitter battery, transmitter keyless control module bracket, keyless control module

bracket ground screw or keyless control module circuit.

POSSIBLE

CAUSE

•

Malfunction in transmitter battery, transmitter, keyless control module bracket, keyless control module

bracket ground screw or keyless control module circuit

— Transmitter battery, transmitter, keyless control module bracket, keyless control module bracket

ground screw or keyless control module malfunction

STEP

INSPECTION

ACTION

1

INSPECT TRANSMITTER BATTERY

INSTALLATION AND TYPE

•

Visually inspect transmitter battery.

•

Are below items okay?

— Transmitter battery installation (correct polarity)

— Battery type (CR2025)

Yes Go to next step.

No

Set transmitter battery properly or replace with specified

transmitter battery (CR2025), then go to Step 8.

2

INSPECT TRANSMITTER BATTERY TERMINALS

FOR RUST AND POOR CONNECTION

•

Visually inspect transmitter.

— Is there rust on transmitter battery terminals

(positive or negative pole)?

— Is there poor connection between terminals

and battery?

Yes Replace transmitter battery or repair transmitter battery

terminal, then go to Step 8.

No

Go to next step.

3

INSPECT TRANSMITTER BATTERY

•

Inspect transmitter battery.

•

Is battery voltage normal?

Yes Go to next step.

No

Replace transmitter battery, then go to Step 8.

4

INSPECT KEYLESS CONTROL MODULE

BRACKET INSTALLATION

•

Is keyless control module bracket installed

securely?

Yes Go to next step.

No

Install bracket securely, then go back to Step 6 of keyless

entry system preliminary inspection.

5

INSPECT GROUND SCREW INSTALLATION

BETWEEN KEYLESS CONTROL MODULE AND

KEYLESS CONTROL MODULE BRACKET

•

Are keyless control module and keyless control

module bracket connected securely to ground

screw?

Yes Go to next step.

No

Install screw securely, then go back to Step 6 of keyless

entry system preliminary inspection.

6

CHECK TO SEE WHETHER MALFUNCTION IS IN

TRANSMITTER BATTERY OR ELSEWHERE

•

Replace with a known good transmitter battery.

•

Does keyless entry system operate properly?

Yes Replace transmitter battery, then go to Step 8.

No

Go to next step.

7

CHECK TO SEE WHETHER MALFUNCTION IS IN

TRANSMITTER OR KEYLESS CONTROL MODULE

•

Reprogram keyless control module ID code

using another known good transmitter.

•

Does keyless entry system operate properly?

Yes Replace transmitter and reprogram transmitter ID code,

then go to next step.

No

Replace keyless control module and reprogram keyless

control module ID code, then go to next step.

8

RECHECK MALFUNCTION SYMPTOM AFTER

REPAIR

•

Does keyless entry system operate properly?

Yes Troubleshooting completed.

Explain repairs to customer.

No

Recheck malfunction symptoms, then repeat from Step 1 if

malfunction recurs.

1712-1U-01G(09-03).fm 7 ページ 2001年6月29日 金曜日 午前10時28分