Mazda Protege 5. Manual - part 158

CHARGING SYSTEM

01–17–2

Load test chart

Battery positive voltage with load

Back-up Current

1. Verify that the ignition switch is off and that the ignition key has been removed.

2. Disconnect the negative battery cable.

Caution

••••

Operating electrical loads while measuring the back-up current can damage the circuit tester.

3. Measure the back-up current between the negative battery terminal and the negative battery cable.

(1) If the current exceeds the maximum, remove the fuse in the main fuse block and the fuse block one by one

while measuring the back-up current.

(2) Inspect and repair harnesses and connectors of the fuse at which the current reduces.

Back-up current

20 mA max.

End Of Sie

BATTERY RECHARGING

Warning

••••

Hydrogen gas is produced during normal battery operation. A battery-related explosion can cause

serious injury. Keep all flames (including cigarettes), heat, and sparks away from the top and

surrounding area of open battery cells.

Caution

••••

When disconnecting the battery, remove the negative cable first and install it last to prevent

damage to electrical components or the battery.

••••

To prevent damage to electrical components or the battery, turn all accessories off and stop the

engine before performing maintenance or recharging the battery.

••••

Do not quick charge for over 30 minutes. It will damage the battery.

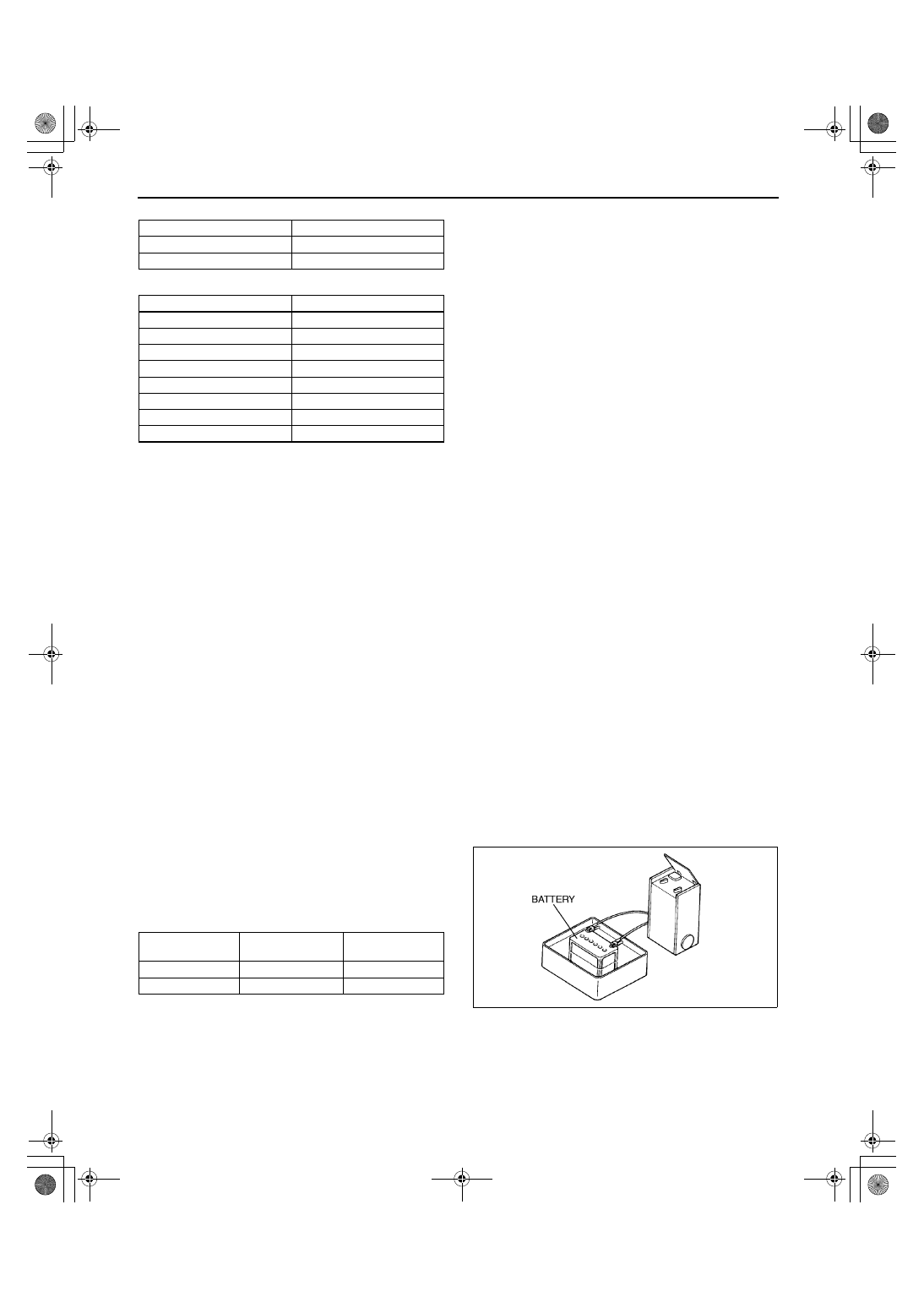

1. Place a battery in a pan of water to prevent it from

overheating. The water level should come up

about halfway on the battery. Keep water off the

top of the battery.

2. Connect a battery charger to the battery.

3. Adjust the charging current as follows.

4. After the battery has been recharged, measure

the battery positive voltage and verify that the

battery keeps specified voltage for more than 1 hour.

•

If not as specified, replace the battery.

Specification

Above 12.4 V

End Of Sie

Battery

Load (A)

50D20L

150

75D23L

195

Approximate battery temp.

Minimum voltage (V)

21

°

C {70

°

F}

9.6

15

°

C {60

°

F}

9.5

10

°

C {50

°

F}

9.4

4

°

C {40

°

F}

9.3

–1

°

C {30

°

F}

9.1

–7

°

C {20

°

F}

8.9

–12

°

C {10

°

F}

8.7

–18

°

C {0

°

F}

8.5

Battery type

(5-hour rate)

Slow charge (A)

Quick charge

(A)/(30 min.)

50D20L (40)

4.0—5.0

25

75D23L (52)

5.5—6.5

35

X3U117WA1

1712-1U-01G(01-17).fm 2 ページ 2001年6月29日 金曜日 午前9時47分