Mazda Protege 5. Manual - part 155

EMISSION SYSTEM

01–16–10

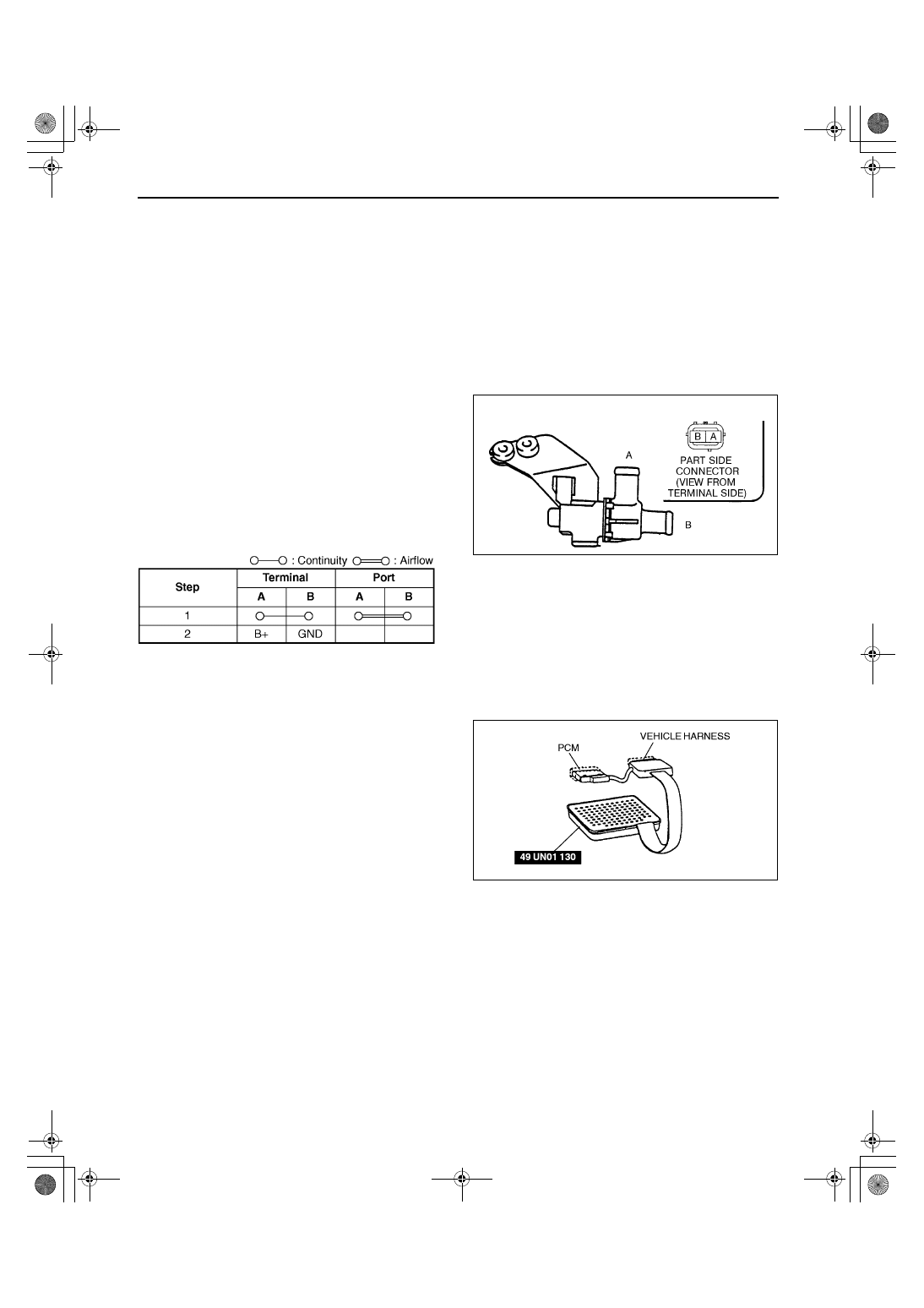

CANISTER DRAIN CUT VALVE (CDCV) INSPECTION

A3U011618743W02

Simulation Test

1. Carry out the “Evaporative Emission Control System Inspection”. (See 01–03A–56 Evaporative System Leak

Inspection Using Vacuum Pump.) (See 01–03B–55 Evaporative System Leak Inspection Using Vacuum

Pump.)

•

If not as specified, perform the following inspection for the CDCV.

Airflow Inspection

Note

•

Perform the following test only when directed.

1. Disconnect the negative battery cable.

2. Remove the CDCV. (See 01–16–9 CANISTER

DRAIN CUT VALVE (CDCV) REMOVAL/

INSTALLATION.)

3. Inspect airflow between the ports under the

following conditions.

•

If not as specified, replace the CDCV.

•

If as specified but the “Simulation Test” is

failed, inspect evaporative hoses for improper

routing, kinks or leakage, and carry out the

“Circuit Open/Short Inspection” and repair or

replace the parts if necessary.

Circuit Open/Short Inspection

1. Remove the PCM.

2. Connect the SST (104 Pin Breakout Box) to the

PCM as shown.

3. Tighten the connector attaching screw.

Tightening torque

7.9—10.7 N·m {80—110 kgf·cm, 69.5—95.4

in·lbf}

Y3U116WA1

X3U116WCA

Y3U116WAG

1712-1U-01G(01-16).fm 10 ページ 2001年6月29日 金曜日 午前9時45分