Mazda Protege 5. Manual - part 105

SYMPTOM TROUBLESHOOTING [ENGINE CONTROL SYSTEM (FS)]

01–03B–13

01–03B

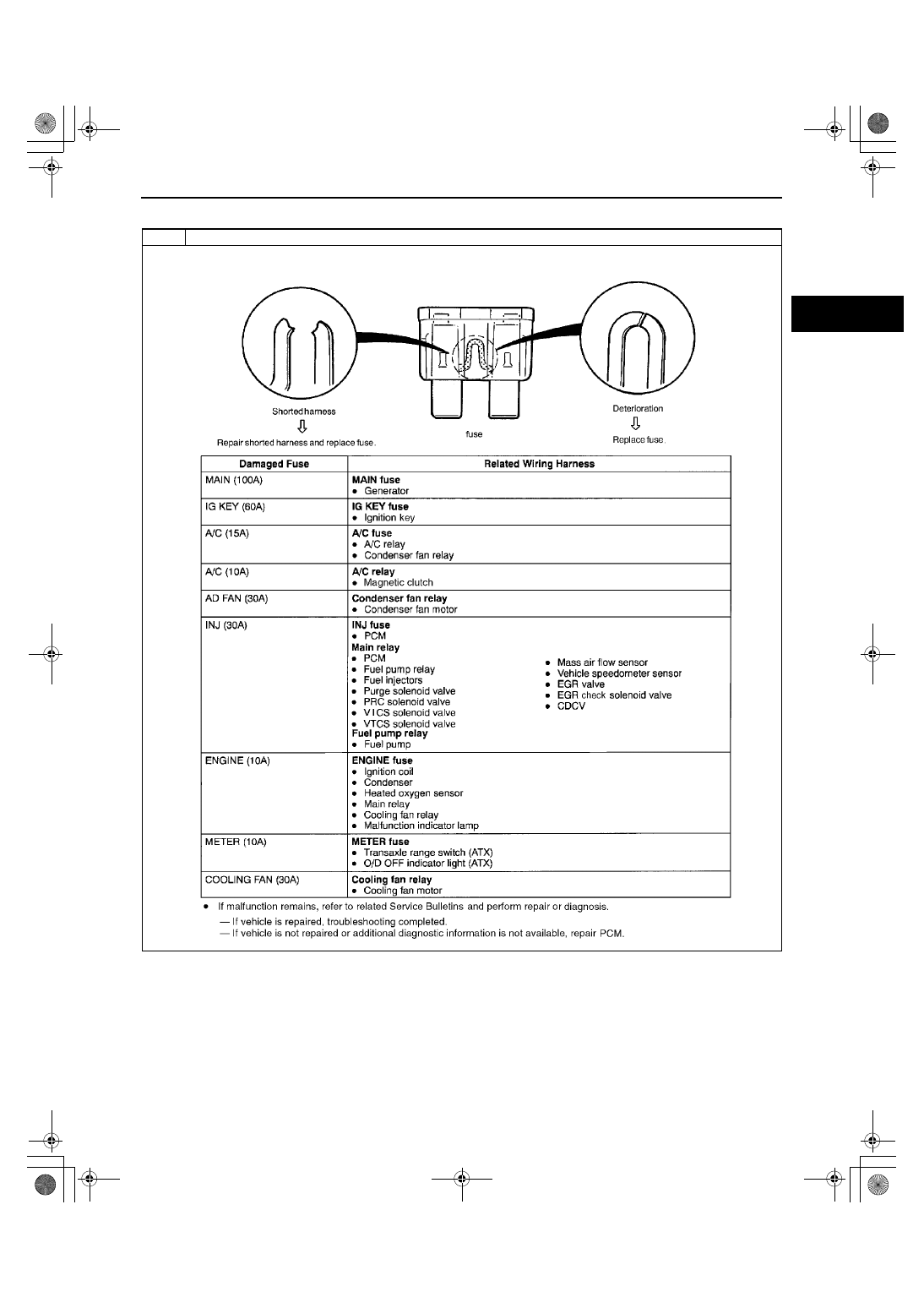

NO.1 MELTING OF MAIN OR OTHER FUSES [FS]

A3U010318881W06

End Of Sie

1

Melting of main or other fuses

[TROUBLESHOOTING HINTS]

Inspection condition of fuse.

1712-1U-01G(01-03B).fm 13 ページ 2001年6月29日 金曜日 午前9時33分