Mazda Protege 5. Manual - part 90

SYMPTOM TROUBLESHOOTING [ENGINE CONTROL SYSTEM (ZM)]

01–03A–13

01–03A

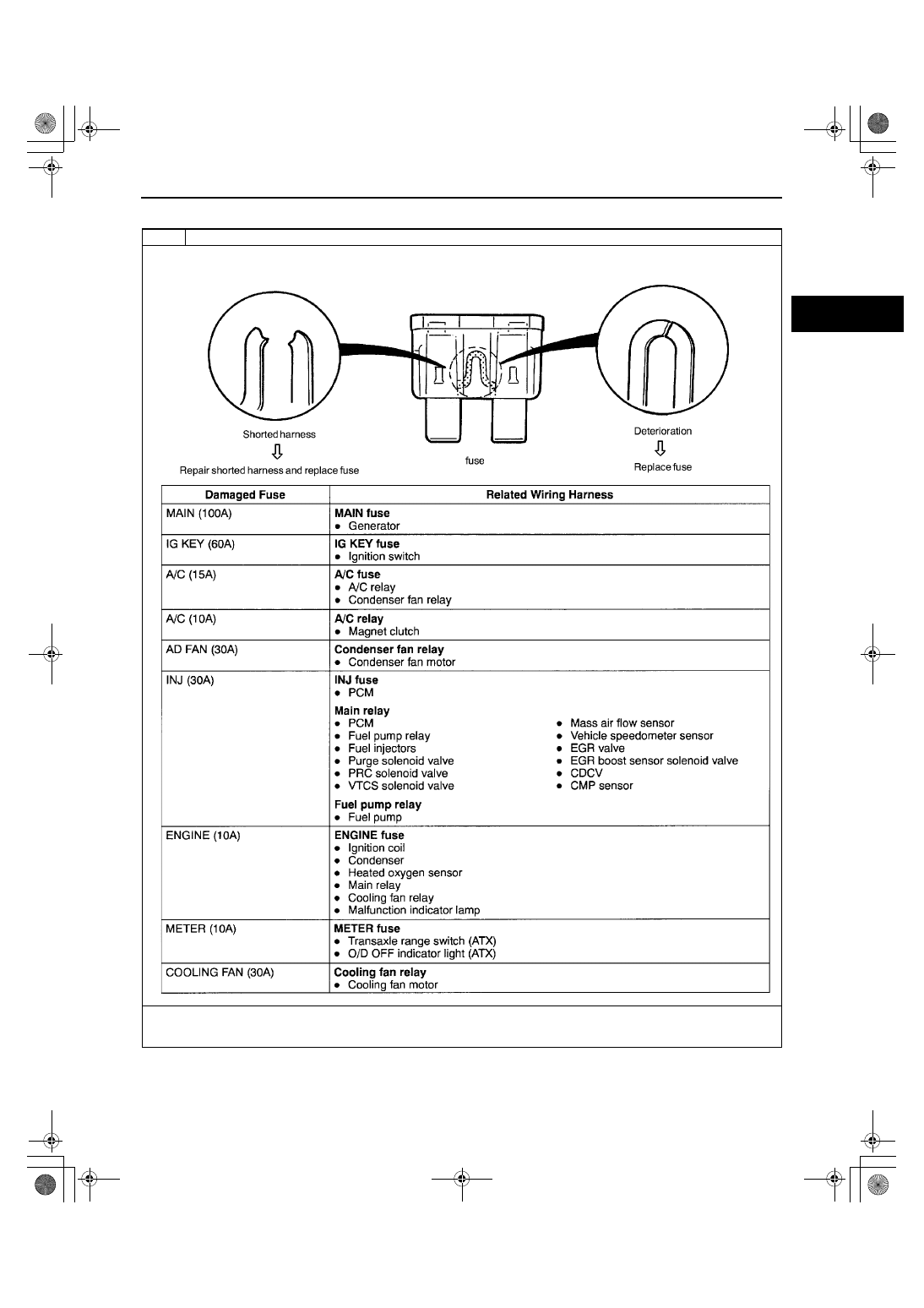

NO.1 MELTING OF MAIN OR OTHER FUSES [ZM]

A3U010318881W43

End Of Sie

1

Melting of main or other fuses

[TROUBLESHOOTING HINTS]

Inspect condition of fuse.

•

If malfunction remains, refer to related Service Bulletins and perform repair or diagnosis.

— If vehicle is repaired, troubleshooting completed.

— If vehicle is not repaired or additional diagnostic information is not available, replace PCM.

1712-1U-01G(01-03A).fm 13 ページ 2001年6月29日 金曜日 午後4時45分