Mazda Protege 5. Manual - part 78

ON-BOARD DIAGNOSTIC [ENGINE CONTROL SYSTEM (FS)]

01–02B–132

End Of Sie

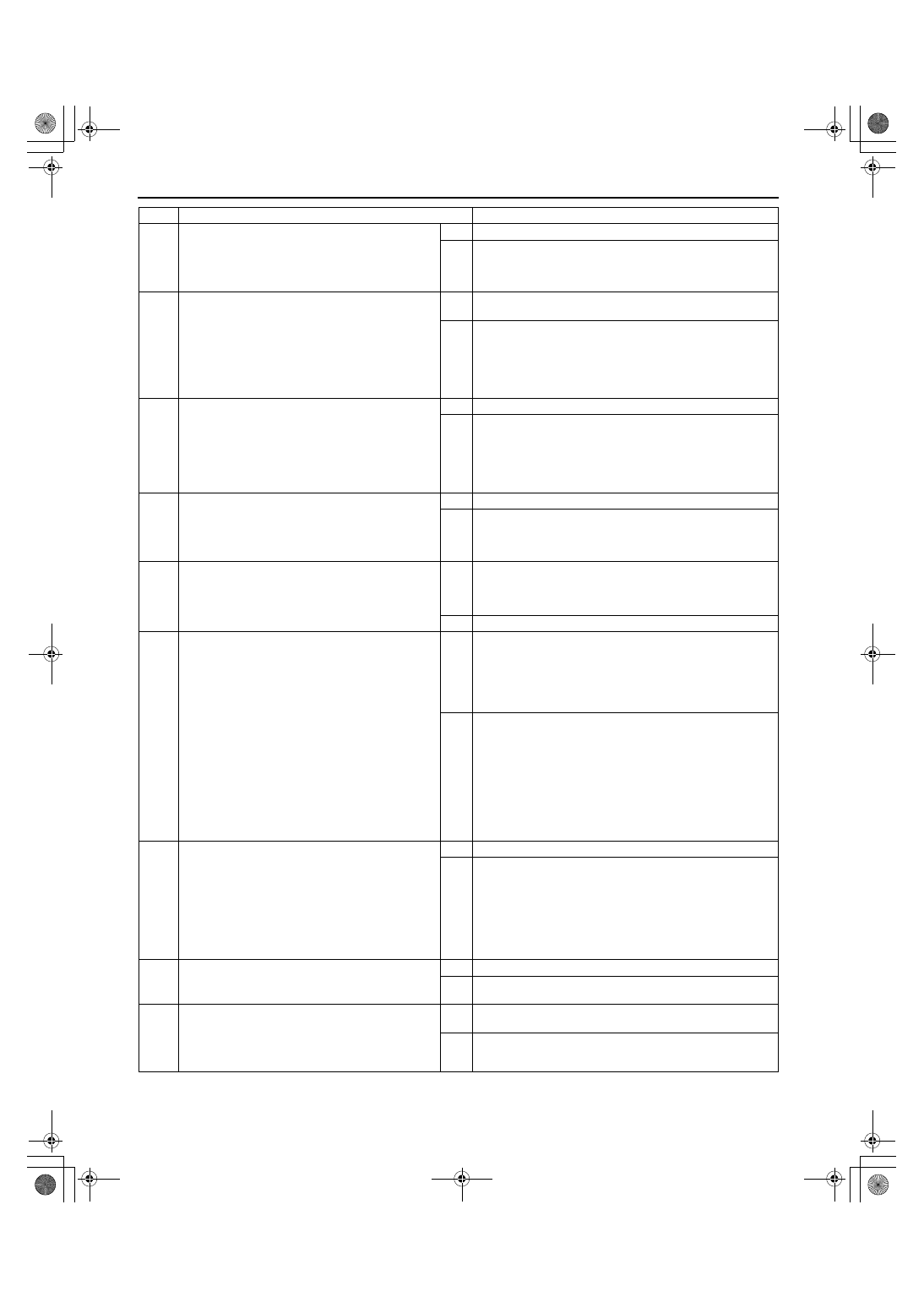

4

INSPECT FOR OPERATION SOUND OF CDCV

•

Perform CDCV inspection.

(See 01–16–10 CANISTER DRAIN CUT

VALVE (CDCV) INSPECTION.)

•

Is CDCV okay?

Yes Go to next step.

No

Replace it if necessary, then go to Step 9.

5

INSPECT PURGE SOLENOID VALVE

•

Disconnect vacuum hose that connects to

intake manifold from purge solenoid valve.

•

Connect vacuum pump to purge solenoid

valve.

•

Pump vacuum several times and wait a few

seconds.

•

Does vacuum hold?

Yes Disconnect vacuum pump and connect vacuum hose to

purge solenoid valve. Go to next step.

No

Inspect purge solenoid valve and related harness. Replace

it if necessary, then go to Step 9.

6

INSPECT CHARCOAL CANISTER FOR

CLOGGING

•

Remove charcoal canister and inspect for

clogging.

(See 01–16–9 CHARCOAL CANISTER

INSPECTION.)

•

Is it okay?

Yes Go to next step.

No

Replace charcoal canister, then go to Step 9.

7

INSPECT FUEL TANK PRESSURE SENSOR

•

Inspect fuel tank pressure sensor.

(See 01–40B–40 FUEL TANK PRESSURE

SENSOR INSPECTION [FS].)

•

Is it okay?

Yes Go to next step.

No

Replace fuel tank pressure sensor, then go to Step 9.

8

INSPECT AIR FILTER FOR CLOGGING

•

Remove and inspect air filter connected to

CDCV for clogging.

•

Is it okay?

Yes Inspect for clogging in following area:

•

From charcoal canister to CDCV

•

Drain passage including check valve

— Repair or replace faulty area, then go to next step.

No

Repair or replace air filter, then go to next step.

9

VERIFY MONITORING CONDITION FOR

EVAPORATIVE SYSTEM TEST

•

Make sure to reconnect all disconnected

connectors.

•

Turn ignition key to ON (Engine OFF).

•

Clear DTC from memory using WDS or

equivalent.

•

Verify that following conditions are met.

— BARO: 69.7 kPa {523 mmHg, 20.5 inHg}

or higher

— ECT: –10.0—20.0

°°°°

C {14.0—68.0

°°°°

F} [at

barometric pressure 69.7 kPa {523 mmHg,

20.5 inHg}]

— IAT: –10—55

°°°°

C {50—131

°°°°

F}

— Fuel tank level: 15—85%

•

Is there any condition out of specification?

Yes Take corrective action (e.g. cool down engine), then repeat

this step.

Note

•

Readings need to be in the indicated ranges to

perform Drive Mode 4.

No

Go to next step.

10

MONITOR EVAP SYSTEM BY DRIVE MODE 4

•

Run Drive Mode 4.

(See 01–02B–12 Mode 4 (EVAP system repair

verification drive mode).)

•

Stop vehicle and access ON BOARD SYSTEM

READINESS TESTS to inspect Drive Mode

completion status.

•

Has EVAPORATIVE PURGE SYSTEM been

monitored?

Yes Go to next step.

No

Go back to Step 9.

11

VERIFY TROUBLESHOOTING OF DTC P1450

COMPLETED

•

Is pending code of same DTC present?

Yes Replace PCM, then go to next step.

No

Go to next step.

12

VERIFY AFTER REPAIR PROCEDURE

•

Perform “After Repair Procedure”.

(See 01–02B–9 AFTER REPAIR

PROCEDURE [FS].)

•

Is there any DTC present?

Yes Go to applicable DTC inspection.

(See 01–02B–15 DTC TABLE [FS].)

No

Troubleshooting completed.

STEP

INSPECTION

ACTION

1712-1U-01G(01-02B).fm 132 ページ 2001年6月29日 金曜日 午後3時24分