Mazda Protege 5. Manual - part 73

ON-BOARD DIAGNOSTIC [ENGINE CONTROL SYSTEM (FS)]

01–02B–112

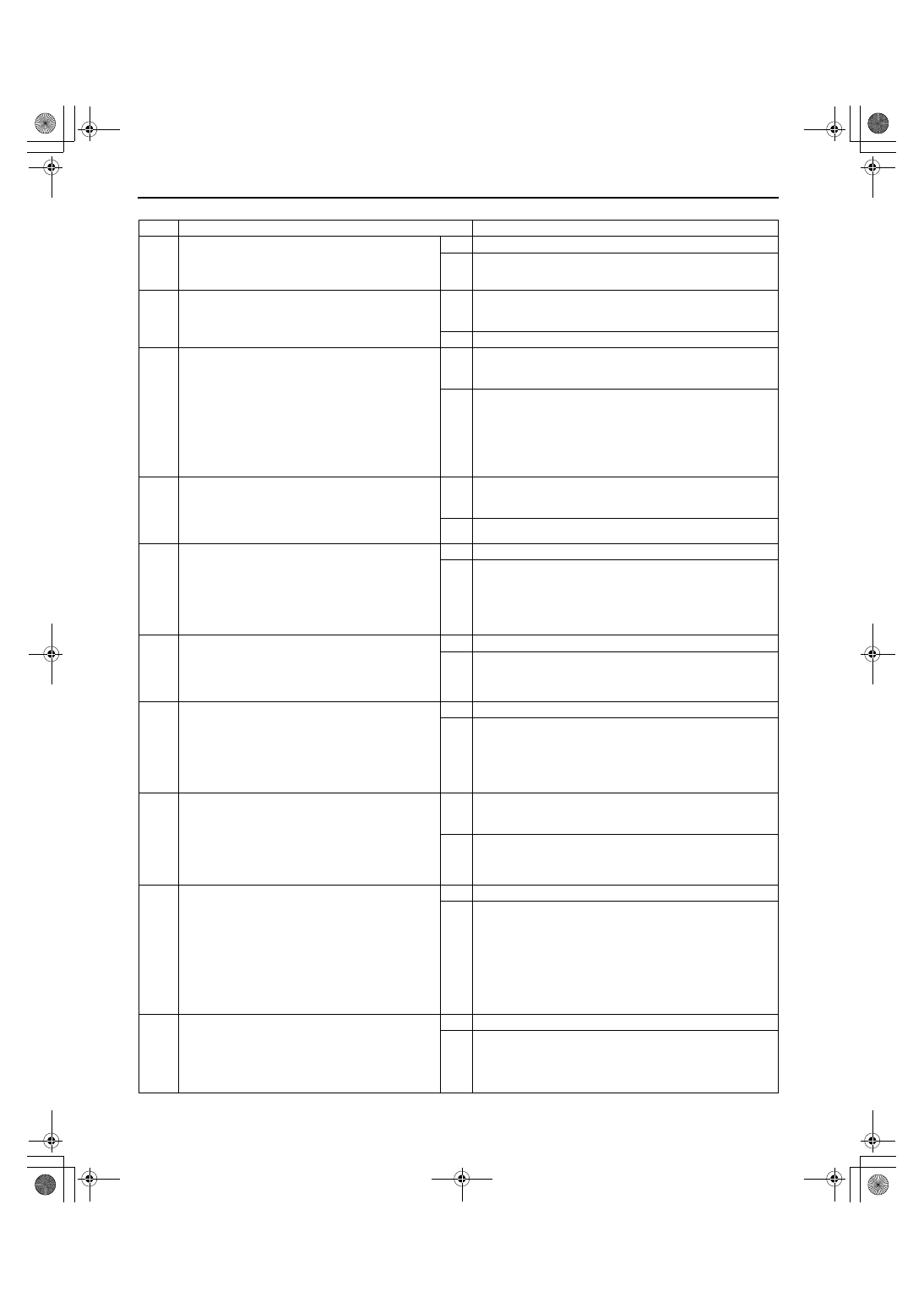

Diagnostic procedure

STEP

INSPECTION

ACTION

1

VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•

Has FREEZE FRAME PID DATA been

recorded?

Yes Go to next step.

No

Record FREEZE FRAME PID DATA on repair order, then

go to next step.

2

VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•

Check for related Service Bulletins availability.

•

Is any related repair information available?

Yes Perform repair or diagnosis according to available repair

information.

•

If vehicle is not repaired, go to next step.

No

Go to next step.

3

VERIFY CURRENT INPUT SIGNAL STATUS-IS

CONCERN INTERMITTENT OR CONSTANT

•

Connect WDS or equivalent to DLC-2.

•

Start engine.

•

Access VS PID using WDS or equivalent.

— Vehicle speed 20 km/h {12.4 mph}: 20km/

h {12.4 mph}

— Vehicle speed 40 km/h {24.8 mph}: 40km/

h {24.8 mph}

•

Are PID readings within specification?

Yes Go to intermittent concern troubleshooting procedure.

(See 01–03B–4 INTERMITTENT CONCERN

TROUBLESHOOTING [FS].)

No

Go to next step.

4

CHECK INPUT/OUTPUT CHECK MODE

•

Turn ignition key to ON (engine OFF).

•

Is instrument cluster DTCs 10 or 12 detected?

(See 09–22–5 INSTRUMENT CLUSTER

INPUT/OUTPUT CHECK MODE.).

Yes DTC 10 and/or 12 displayed: Inspect instrument cluster.

(See 09–22–5 INSTRUMENT CLUSTER INPUT/OUTPUT

CHECK MODE.)

No

Go to next step.

5

INSPECT PCM CONNECTOR FOR POOR

CONNECTION

•

Turn ignition key to OFF.

•

Disconnect PCM connector.

•

Check for poor connection (damaged/pulled-

out terminals, corrosion, etc.).

•

Are terminals okay?

Yes Go to next step.

No

Repair or replace pin or connector, then go to Step 11.

6

INSPECT CRUISE CONTROL MODULE

CONNECTOR

•

Disconnect cruise control module connector.

•

Inspect for bent terminals.

•

Are terminals okay?

Yes Go to next step.

No

Repair terminals, then go to Step 11.

7

INSPECT INSTRUMENT CLUSTER

CONNECTOR FOR POOR CONNECTION

•

Turn ignition key to OFF.

•

Disconnect instrument cluster connector.

•

Check for poor connections (damaged/pulled-

out terminals, corrosion, etc.).

•

Are terminals okay?

Yes Go to next step.

No

Repair or replace terminals, then go to Step 11.

8

INSPECT VOLTAGE

•

Connect PCM connector.

•

Turn ignition key to ON (engine OFF).

•

Measure voltage at instrument cluster terminal

3O (harness-side).

•

Is there 5 V at instrument cluster terminal 3O

(harness-side)?

Yes Replace instrument cluster, then go to Step 11.

(See 09–22–3 INSTRUMENT CLUSTER REMOVAL/

INSTALLATION.)

No

Go to next step.

9

INSPECT INSTRUMENT CLUSTER CIRCUIT

FOR OPEN CIRCUIT

•

Turn ignition key to OFF.

•

Connect breakout box with PCM connector

disconnected.

•

Turn ignition key to ON (engine OFF).

•

Check for continuity between instrument

cluster terminal 3O (harness-side) and

breakout box terminal 58.

•

Is there continuity?

Yes Go to next step.

No

Repair or replace harness, then go to Step 11.

10

INSPECT INSTRUMENT CLUSTER CIRCUIT

FOR SHORT TO GROUND

•

Check for continuity between instrument

cluster terminal 3O (harness-side) and body

ground.

•

Is there continuity?

Yes Repair or replace harness, then go to next step.

No

Replace instrument cluster, then go to next step.

1712-1U-01G(01-02B).fm 112 ページ 2001年6月29日 金曜日 午後3時24分