Mazda Protege 5. Manual - part 61

ON-BOARD DIAGNOSTIC [ENGINE CONTROL SYSTEM (FS)]

01–02B–64

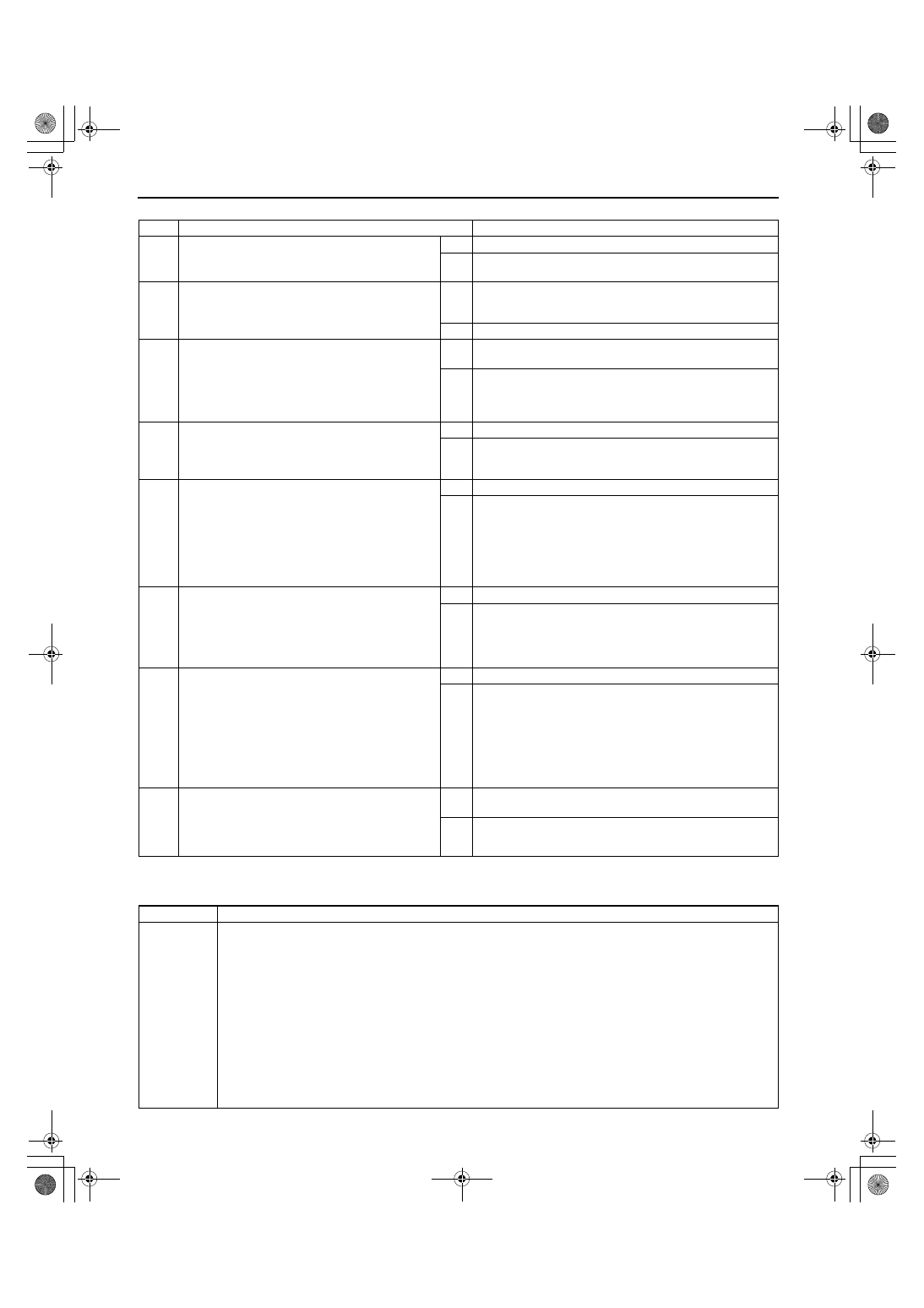

Diagnostic procedure

End Of Sie

DTC P0140 [FS]

A3U010201084W26

STEP

INSPECTION

ACTION

1

VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•

Has FREEZE FRAME DATA been recorded?

Yes Go to next step.

No

Record FREEZE FRAME DATA on repair order, then go to

next step.

2

VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•

Check for related Service Bulletins availability.

•

Is any related repair information available?

Yes Perform repair or diagnosis according to available repair

information.

•

If vehicle is not repaired, go to next step.

No

Go to next step.

3

VERIFY RELATED PENDING OR STORED

DTCS

•

Turn ignition key to OFF, then Start engine.

•

Verify pending codes or stored DTCs using

WDS or equivalent.

•

Is other DTC present?

Yes Go to appropriate DTC troubleshooting procedures.

(See 01–02B–15 DTC TABLE [FS].)

No

Go to next step.

4

IDENTIFY TRIGGER DTC FOR FREEZE FRAME

DATA

•

Is DTC P0138 on FREEZE FRAME DATA?

Yes Go to next step.

No

Go to troubleshooting procedures for DTC on FREEZE

FRAME DATA.

(See 01–02B–15 DTC TABLE [FS].)

5

INSPECT HO2S (REAR) SIGNAL CIRCUIT FOR

SHORT TO POWER SUPPLY CIRCUIT

•

Turn ignition key to OFF.

•

Disconnect HO2S (rear) connector.

•

Turn ignition key to ON (Engine OFF).

•

Measure voltage between HO2S (rear)

terminal A (harness-side) and body ground.

•

Is any voltage reading?

Yes Replace short to power supply circuit, then go to Step 7.

No

Go to next step.

6

VERIFY CURRENT INPUT SIGNAL STATUS

•

Start engine.

•

Access O2S12 PID using WDS or equivalent.

•

Verify PID while racing engine at least 10

times (in neutral position).

•

Does PID reading stay above 0.45 V?

Yes Replace HO2S (rear), then go to next step.

No

Go to next step.

7

VERIFY TROUBLESHOOTING OF DTC P0138

COMPLETED

•

Make sure to reconnect all disconnected

connectors.

•

Turn ignition key to ON (Engine OFF).

•

Clear DTC from memory using WDS or

equivalent.

•

Run OBD-II DRIVE MODE 1 and 3.

•

Is PENDING CODE of same DTC present?

Yes Replace PCM, then go to next step.

No

Go to next step.

8

VERIFY AFTER REPAIR PROCEDURE

•

Perform “After Repair Procedure”.

(See 01–02B–9 AFTER REPAIR

PROCEDURE [FS].)

•

Is there any DTC present?

Yes Go to applicable DTC inspection.

(See 01–02B–15 DTC TABLE [FS].)

No

Troubleshooting completed.

DTC P0140

HO2S (rear) circuit no activity detected

DETECTION

CONDITION

•

PCM monitors input voltage from HO2S (rear) when the following monitoring conditions are met. If input

voltage from sensor never exceed 0.55 V for 30 seconds, PCM determines that sensor circuit is not

activated.

MONITORING CONDITIONS

— Drive mode 3

— Following conditions are met:

•

Engine speed is above 1,500 rpm.

•

Engine coolant temperature is above 70

°°°°

C {158

°°°°

F}.

Diagnostic support note

•

This is a continuous monitor (CCM).

•

MIL illuminates if PCM detects the above malfunction condition in two consecutive drive cycles.

•

PENDING CODE is available if PCM detects the above malfunction condition during first drive cycle.

•

FREEZE FRAME DATA is available.

•

DTC is stored in PCM memory.

1712-1U-01G(01-02B).fm 64 ページ 2001年6月29日 金曜日 午後3時24分