Mazda Protege 5. Manual - part 41

ON-BOARD DIAGNOSTIC [ENGINE CONTROL SYSTEM (ZM)]

01–02A–130

Diagnostic procedure

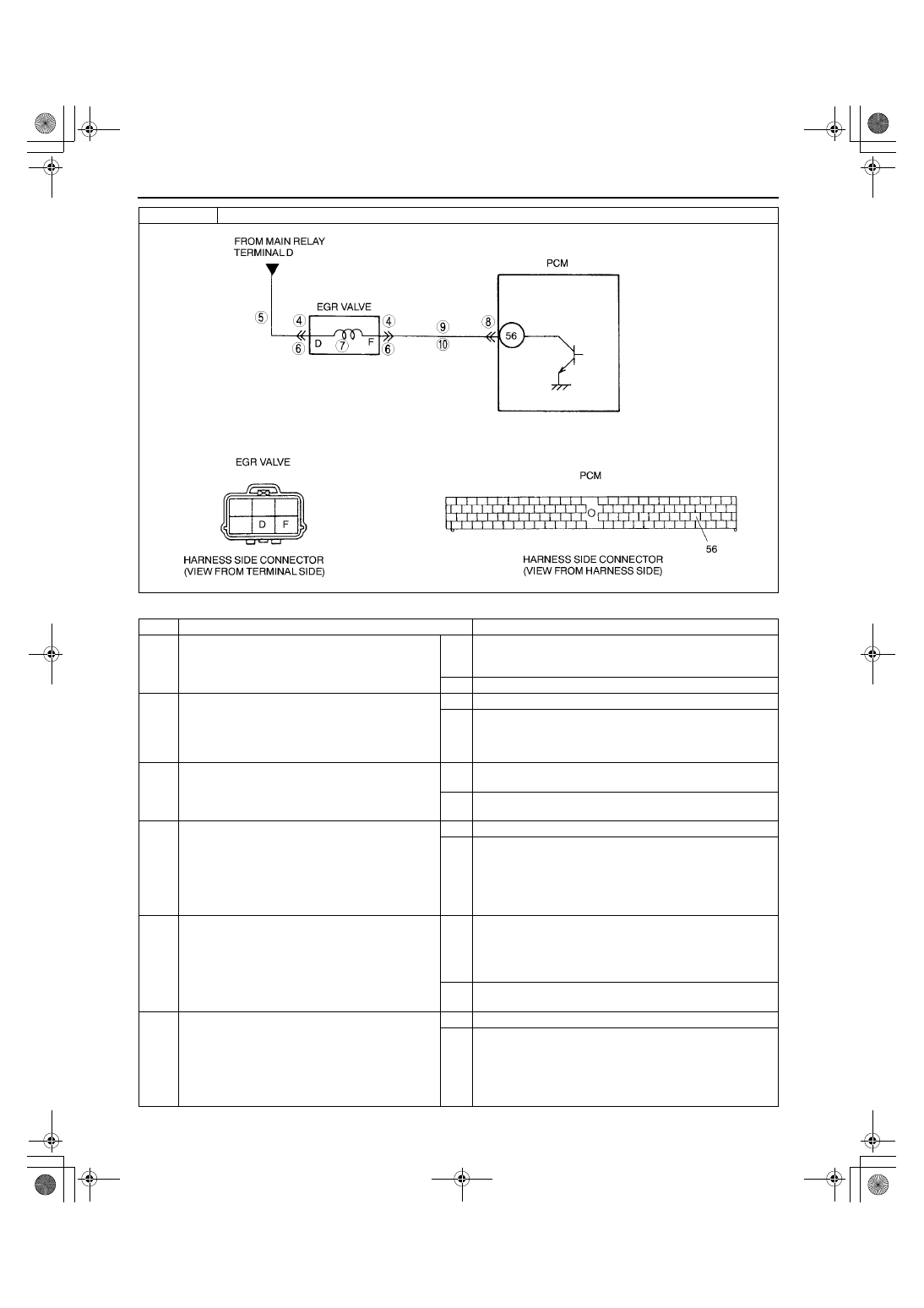

DTC P1499

EGR valve stepping motor coil 4 open or short circuit

STEP

INSPECTION

ACTION

1

VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•

Check for related Service Bulletins availability.

•

Is any repair information available?

Yes Perform repair or diagnosis according to available repair

information.

•

If vehicle is not repaired, go to next step.

No

Go to next step.

2

CLASSIFY INTERMITTENT CONCERN OR

CONTINUOUS CONCERN

•

Turn ignition key to OFF then ON (Engine

OFF).

•

Is same DTC present?

Yes Go to next step.

No

Refer to intermittent concern.

(See 01–03A–4 INTERMITTENT CONCERN

TROUBLESHOOTING [ZM].)

3

CLASSIFY POWER CIRCUIT OR CONTROL

CIRCUIT MALFUNCTION

•

Are same DTC and P1498 present?

Yes Malfunction at EGR valve or power circuit.

Go to next step.

No

Malfunction at EGR valve or control circuit.

Go to Step 6.

4

INSPECT EGR VALVE FOR POOR

CONNECTION

•

Turn ignition key to OFF.

•

Disconnect EGR valve connector.

•

Check for poor connection (damaged/pulled-

out terminals, corrosion, etc.).

•

Is there malfunction?

Yes Repair or replace terminals, then go to Step 11.

No

Go to next step.

5

INSPECT POWER CIRCUIT FOR OPEN

CIRCUIT

•

Turn ignition key to ON (Engine OFF).

•

Measure voltage between EGR valve terminal

D (harness-side) and body ground.

•

Is voltage B+?

Yes Inspect EGR valve coils 3 and 4.

(See 01–16–15 EGR VALVE INSPECTION.)

•

If there is a malfunction, replace EGR valve, and then

go to Step 11.

•

If there is no malfunction, go to Step 11.

No

Repair or replace harness for open circuit, then go to Step

11.

6

INSPECT EGR VALVE FOR POOR

CONNECTION

•

Turn ignition key to OFF.

•

Disconnect EGR valve connector.

•

Check for poor connection (damaged/pulled-

out terminals, corrosion, etc.).

•

Is there malfunction?

Yes Repair or replace terminals, then go to Step 11.

No

Go to next step.

1712-1U-01G(01-02A).fm 130 ページ 2001年6月29日 金曜日 午後2時20分