Mazda Protege 5. Manual - part 16

ON-BOARD DIAGNOSTIC [ENGINE CONTROL SYSTEM (ZM)]

01–02A–30

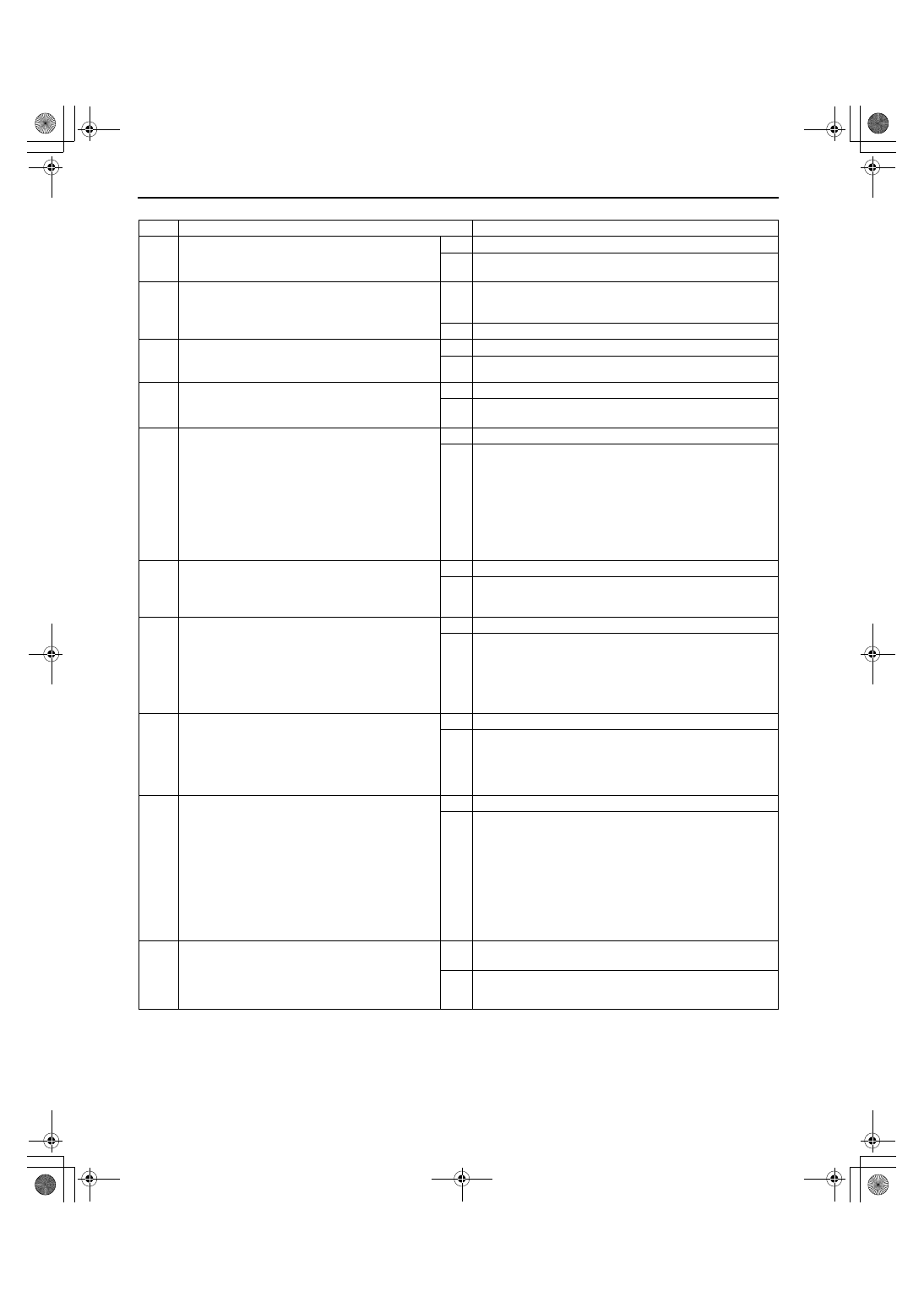

Diagnostic procedure

End Of Sie

STEP

INSPECTION

ACTION

1

VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•

Has FREEZE FRAME DATA been recorded?

Yes Go to next step.

No

Record FREEZE FRAME DATA on repair order, then go to

next step.

2

VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•

Check for related Service Bulletins availability.

•

Is any related repair information available?

Yes Perform repair or diagnosis according to available repair

information.

•

If vehicle is not repaired, go to next step.

No

Go to next step.

3

VERIFY STORED DTC

•

Turn ignition key to OFF then start engine.

•

Has DTC P1487 been stored?

Yes Inspect and repair DTC P1487.

No

Go to next step.

4

IDENTIFY TRIGGER DTC FOR FREEZE FRAME

DATA

•

Is DTC P0106 on FREEZE FRAME DATA?

Yes Go to next step.

No

Go to troubleshooting procedures for DTC on FREEZE

FRAME DATA.

5

INSPECT CONNECTION OF EGR BOOST

SENSING RELATED VACUUM HOSES

•

Inspect the following vacuum hoses for

looseness, damage, improper connection and/

or clogging.

— From EGR boost sensor to EGR boost

sensor solenoid

— From EGR boost sensor solenoid to intake

manifold

•

Are they okay?

Yes Go to next step.

No

Repair or replace vacuum hose, then go to Step 9.

6

INSPECT EGR BOOST SENSOR SOLENOID

AIR FILTER FOR CLOGGING

•

Has EGR boost sensor solenoid air filter been

clogged?

Yes Repair air clogging, then go to Step 9.

No

Go to next step.

7

INSPECT EGR BOOST SENSOR SOLENOID

VALVE FOR WHETHER STUCK OPEN OR

CLOSED

•

Inspect EGR boost sensor solenoid valve.

(See 01–16–17 EGR BOOST SENSOR

SOLENOID VALVE INSPECTION)

•

Is EGR boost sensor solenoid okay?

Yes Go to next step.

No

Replace EGR boost sensor solenoid, then go to Step 9.

8

INSPECT EGR BOOST SENSOR FOR

WHETHER STUCK OPEN OR CLOSED

•

Inspect EGR boost sensor.

(See 01–40A–38 EGR BOOST SENSOR

INSPECTION [ZM])

•

Is EGR boost sensor okay?

Yes Go to next step.

No

Replace EGR boost sensor, then go to next step.

9

VERIFY TROUBLESHOOTING OF DTC P0106

COMPLETED

•

Make sure to reconnect all disconnected

connectors.

•

Turn ignition key to ON (Engine OFF).

•

Clear DTC from memory using WDS or

equivalent.

•

Run OBD-ll DRIVE MODE 1, 2 and 3.

(See 01–02A–11 OBD-II DRIVE MODE [ZM])

•

Stop vehicle.

•

Is same DTC present?

Yes Replace PCM, then go to next step.

No

Go to next step.

10

VERIFY AFTER REPAIR PROCEDURE

•

Perform “After Repair Procedure”.

(See 01–02A–10 AFTER REPAIR

PROCEDURE [ZM].)

•

Is there any DTC present?

Yes Go to applicable DTC inspection.

(See 01–02A–15 DTC TABLE [ZM].)

No

Troubleshooting completed.

1712-1U-01G(01-02A).fm 30 ページ 2001年6月29日 金曜日 午後2時20分