Mazda Protege 5. Manual - part 3

GENERAL INFORMATION

00–00–9

00–00

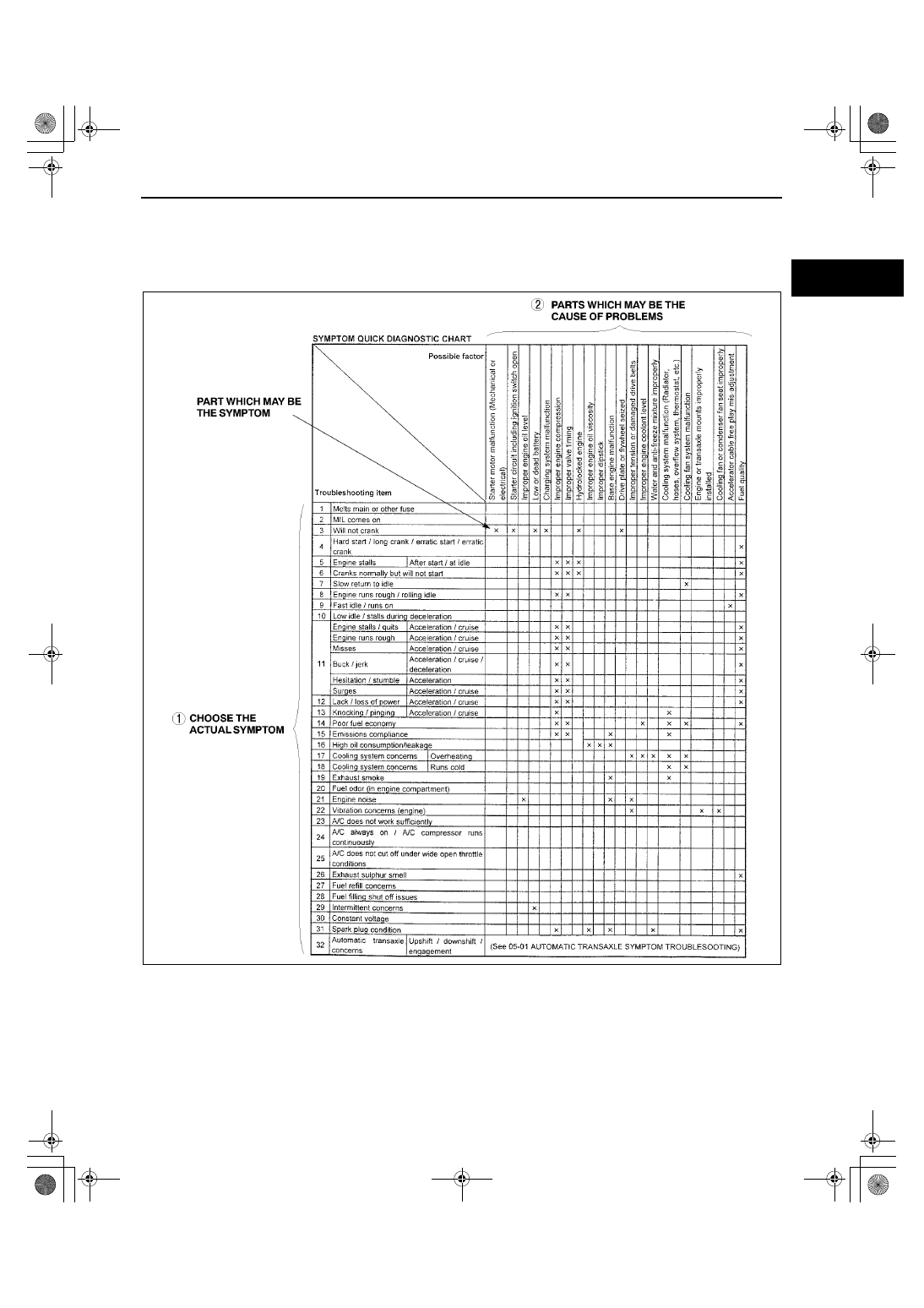

Using the quick diagnosis chart

•

The chart lists the relation between the symptom and the cause of the malfunction.

•

The chart is effective in quickly narrowing down the relation between symptom and cause of the malfunction. It

also specifies the area of the common cause when multiple malfunction symptoms occur.

•

The appropriate diagnostic inspection relating to malfunction cause as specified by the symptoms can be

selected by looking down the diagnostic inspection column of the chart.

YLU000WAA