Mazda 5. Manual - part 51

05–17–124

AUTOMATIC TRANSAXLE

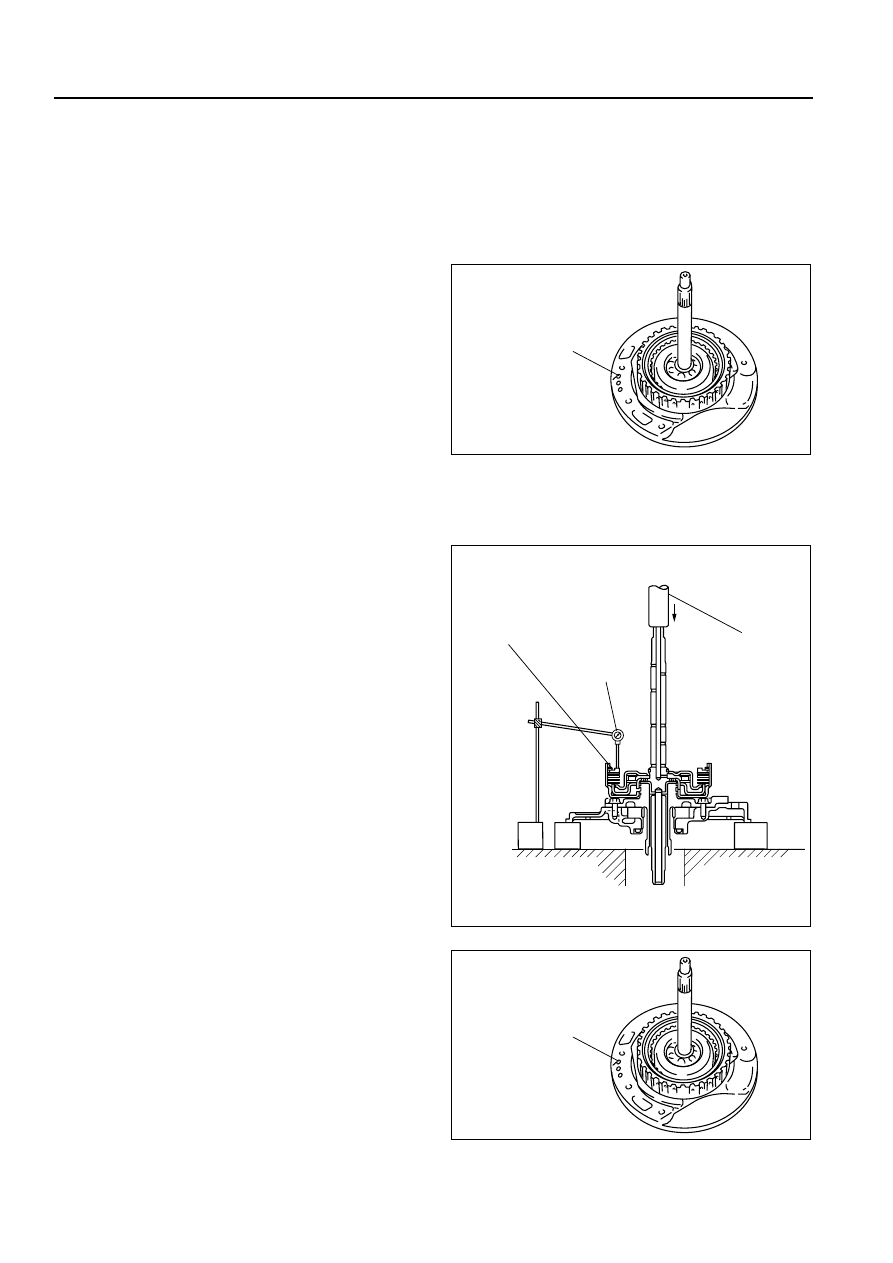

Forward Clutch Preinspection

Clutch operation

1. Set the forward clutch onto the oil pump.

Caution

• Applying compressed air to the assembled clutch pack for longer than 3 s at a time will damage

the seal.

Do not apply compressed air for more than the aforementioned time when testing the system.

2. Inspect the clutch operation by applying

compressed air through the fluid passages

shown.

Air pressure

392 kPa {4.0 kgf/cm

2

, 57 psi} max.

3. If not as specified, replace parts as necessary.

(See 05–17–56 FORWARD CLUTCH

DISASSEMBLY/ASSEMBLY.)

Clutch clearance

1. Measure the forward clutch clearance.

(1) Install the forward clutch in the oil pump, and set the dial gauge.

(2) Secure the forward clutch by lightly pressing

down with a press, etc.

(3) Apply compressed air to the part indicated in

the figure and let the forward clutch piston

stroke three times.

Air pressure

392—441 kPa {4.0—4.5 kgf/cm

2

, 57—63 psi}

(4) Apply compressed air and operate the

forward clutch piston. Read the value when

the indicator of the dial gauge stops.

(5) Release the compressed air and read the dial

gauge when the forward clutch piston is not

operating.

(6) Calculate the forward clutch clearance

according to the following formula:

FORWARD CLUTCH

FLUID PASSAGE

B3E0517A117

PRESS

DIAL GAUGE

RETAINING PLATE

B3E0517A323

FORWARD CLUTCH

FLUID PASSAGE

B3E0517A117