Mazda 5. Manual - part 9

01–10–22

MECHANICAL

Bolt length (mm {in})

Cylinder head bolt (With washer)

Standard: 149.2—145.8 {5.87—5.90}

Maximum: 150.5 {5.91}

Cylinder head bolt (Without washer)

Standard: 145.2—145.8 {5.72—5.74}

Maximum: 146.5 {5.77}

Connecting rod bolt

Standard: 44.7—45.3 {1.75—1.78}

Maximum: 46.0 {1.81}

Main bearing cap bolt (Plastic region

tightening bolt only)

Standard: 110.0—110.6 {4.33—4.35}

Maximum: 113.3{4.38}

End Of Sie

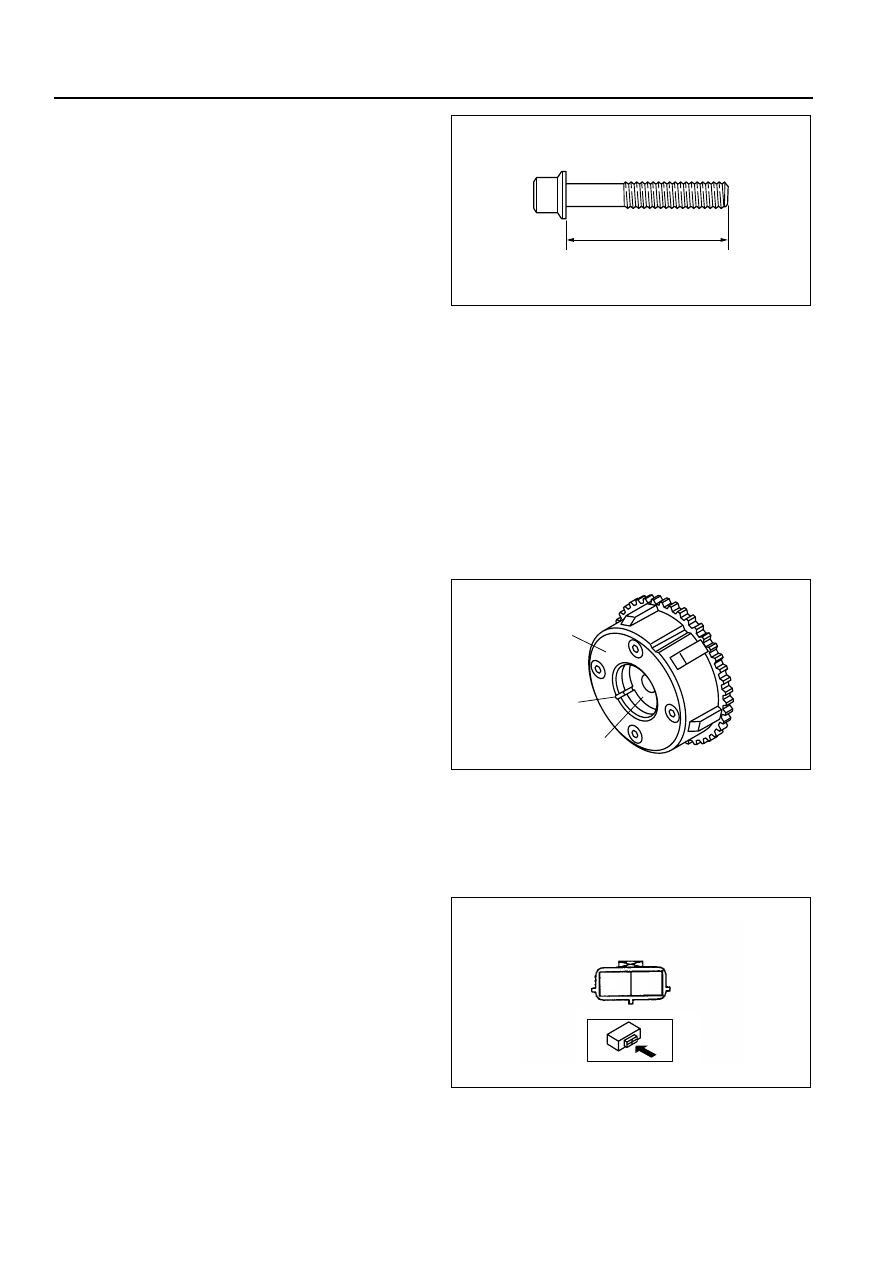

VARIABLE VALVE TIMING ACTUATOR INSPECTION

B3E011000142201

Caution

• Variable valve timing actuator cannot be disassembled because it is a precision unit.

1. Confirm that the groove of the rotor and notch of the cover at the variable valve timing actuator are aligned and

fixed.

• If the notch and the bump are not aligned, rotate the rotor toward the valve timing retard position by hand

until they are in place.

• If the rotor and cover are not fixed even though their notch and groove are aligned, replace the variable

valve timing actuator.

End Of Sie

OIL CONTROL VALVE (OCV) INSPECTION

B3E011014420201

Coil resistance inspection

1. Disconnect the negative battery cable.

2. Disconnect the oil control valve (OCV) connector.

3. Measure the resistance between terminals A and B using an ohmmeter.

• If not as specified, replace the oil control valve (OCV).

Specification

6.9—7.9 ohms [20

°C {68 °F}]

4. Connect the oil control valve (OCV) connector.

Spool valve operation inspection

1. Disconnect the negative battery cable.

2. Remove the oil control valve (OCV).

3. Verify that the spool valve in the oil control valve (OCV) is in the maximum valve timing retard position as

L

B3E0110E088

COVER

NOTCH

ROTOR

B3E0110E089

A

B

OIL CONTROL VALVE (OCV)

B3E2226W002