Mazda X-5. Manual - part 39

CONTROL SYSTEM

01–40–29

01–40

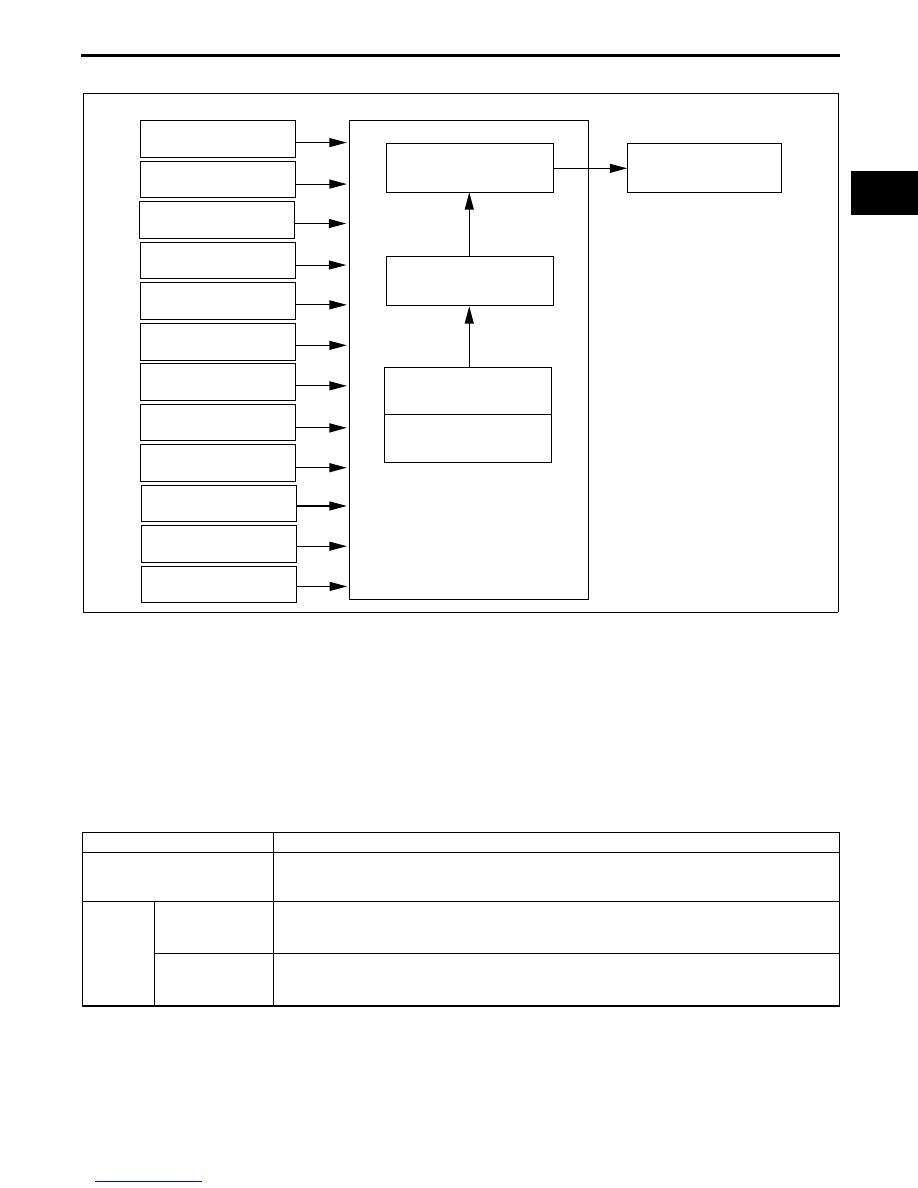

EVAPORATIVE PURGE CONTROL BLOCK DIAGRAM [LF]

E5U014000000N38

End Of Sie

EVAPORATIVE PURGE CONTROL OPERATION [LF]

E5U014000000N39

Determination of Purge Solenoid Valve Energization Time

• The PCM determines the target purge flow amount according to engine operation conditions as the basic flow

amount. The actual operation delays the build-up of operation current from coil inductance and corrects

energization time according to fluctuation in battery voltage to cause operation delay based on the mass of the

needle valve and plunger, and spring resistance. The lower the rate of battery positive voltage, the longer the

energization time.

Calculation Method for Purge Flow Amount

• The PCM determines the purge flow amount through the addition of each correction to the basic purge flow

amount.

Operation Conditions

• For purge control during normal driving, the PCM sends a duty signal to the purge solenoid valve when all of

the following conditions are met.

— Fuel injection control is in the feedback zone or the high load volume increase zone.

— Airflow passage damage related DTC is not stored.

— Engine coolant temperature is 70

°C {158 °F} or more.

End Of Sie

MAF SENSOR

IAT SENSOR

MAP SENSOR

CKP SENSOR

BARO SENSOR

FRONT HO2S

BATTERY

NEUTRAL SWITCH (MT)

TR SWITCH (AT)

PURGE SOLENOID VALVE

ENERGIZATION TIME

PURGE FLOW AMOUNT

BASIC PURGE FLOW

AMOUNT

CORRECTIONS

PURGE SOLENOID

VALVE

PCM

TP SENSOR NO.1, NO.2

ECT SENSOR

BRAKE SWITCH

NO.1, NO.2

E5U140ZT5007

Contents

Calculation or determination method of purge flow amount and correction

Basic purge flow amount

The basic purge flow amount is determined by multiplying the intake air temperature

correction to the purge mass volume which is calculated by multiplying the base purge rate

and the intake air mass volume, which differs according to engine conditions.

Correction

Purge startup

correction

Purpose: Prevents a sudden change in air/fuel ratio during the startup of purge control.

During purge control startup

• When purge control operation conditions are met→correction

Volume decrease

correction

Purpose: Decreases the amount of purge flow and stabilize the air/fuel ratio.

When the fuel injection control feedback correction value is unstable

• According to the front HO2S feedback condition