Mazda X-5. Manual - part 36

CONTROL SYSTEM

01–40–17

01–40

Maximum Cam Retard Mode

Mode execution condition

• When any of the following conditions are met:

— Cranking

— Idling after completion of cleaning mode

— DTC stored for the following devices:

• ECT sensor

• CKP sensor

• CMP sensor

• TP sensor

• MAF sensor

• OCV

Purpose

• Maximum cam retard mode stabilizes engine speed by maximally retarding the valve timing when the engine

speed is low during idling.

Operation

• When the target current in the maximum cam retard mode is fixed at 100 mA. When 100 mA current is

supplied, the OCV opens the hydraulic passage for the retard chamber and hydraulic pressure from the oil

pump is introduced to the retard chamber. Because of this, the variable valve timing actuator is fixed at the

maximum retard position (minimum overlap).

Feedback Hold Mode

Mode execution condition

• Target valve timing and actual valve timing are almost the same.

Purpose

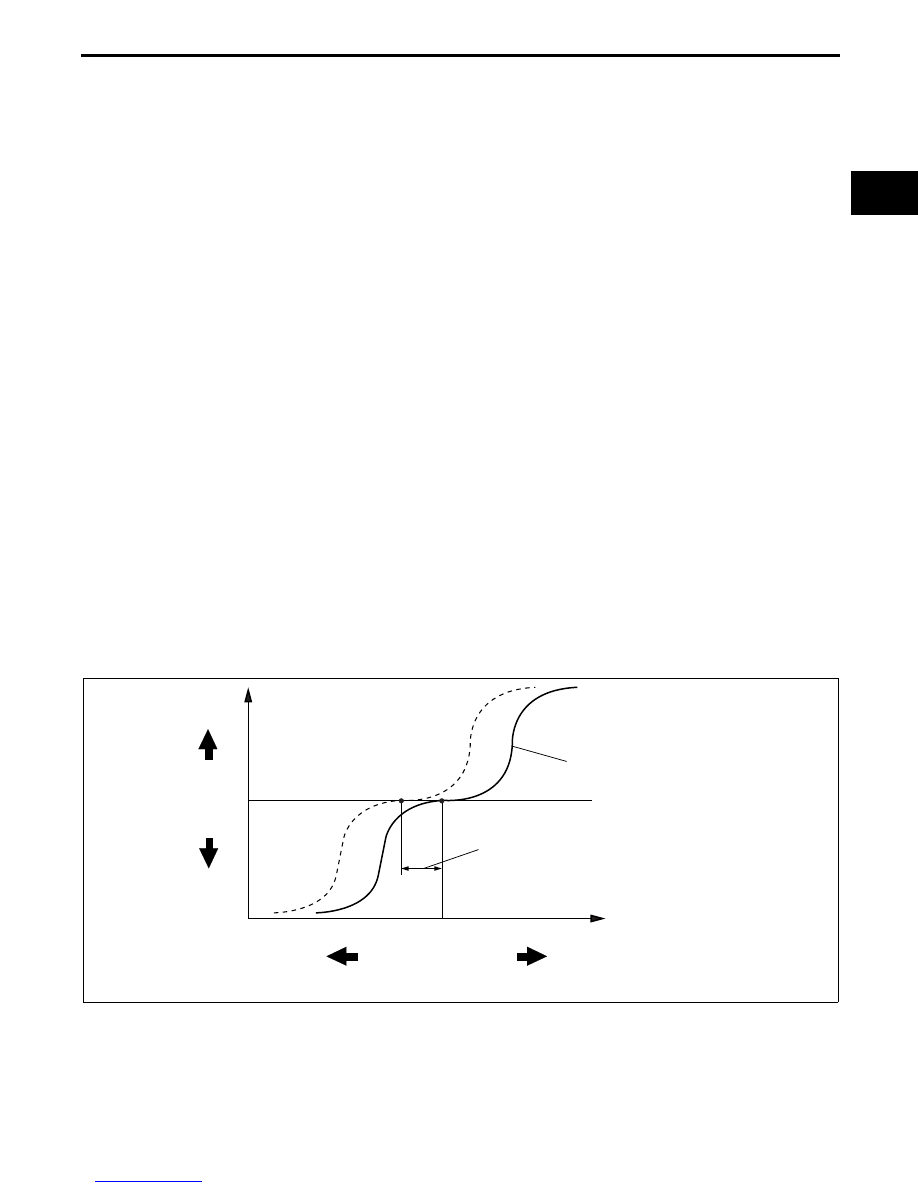

• The feedback hold mode holds the valve timing by returning the OCV spool valve to the neutral position when

target valve timing suitable for the engine operation conditions is obtained.

Operation

• Though the target current in the feedback hold mode is basically around 600 mA, feedback operation is

performed at all times so that the present OCV drive current approaches the target current. Because the hold

current changes due to mechanical variation between engines and deterioration due to aging on OCV internal

parts, the PCM continues to learn the changing current (hold current learning value) to maintain the spool valve

in the neutral position.

ADVANCE SPEED INCREASES

AS INCLINATION INCREASES

CHANGES ACCORDING TO MECHANICAL

VARIANCE AND AGED DETERIORATION

ADVANCE

RETARD

APPROX. 100 mA

APPROX. 600 mA

APPROX. 1,000 mA

OCV OPERATION CURRENT

E5U140ZT5101