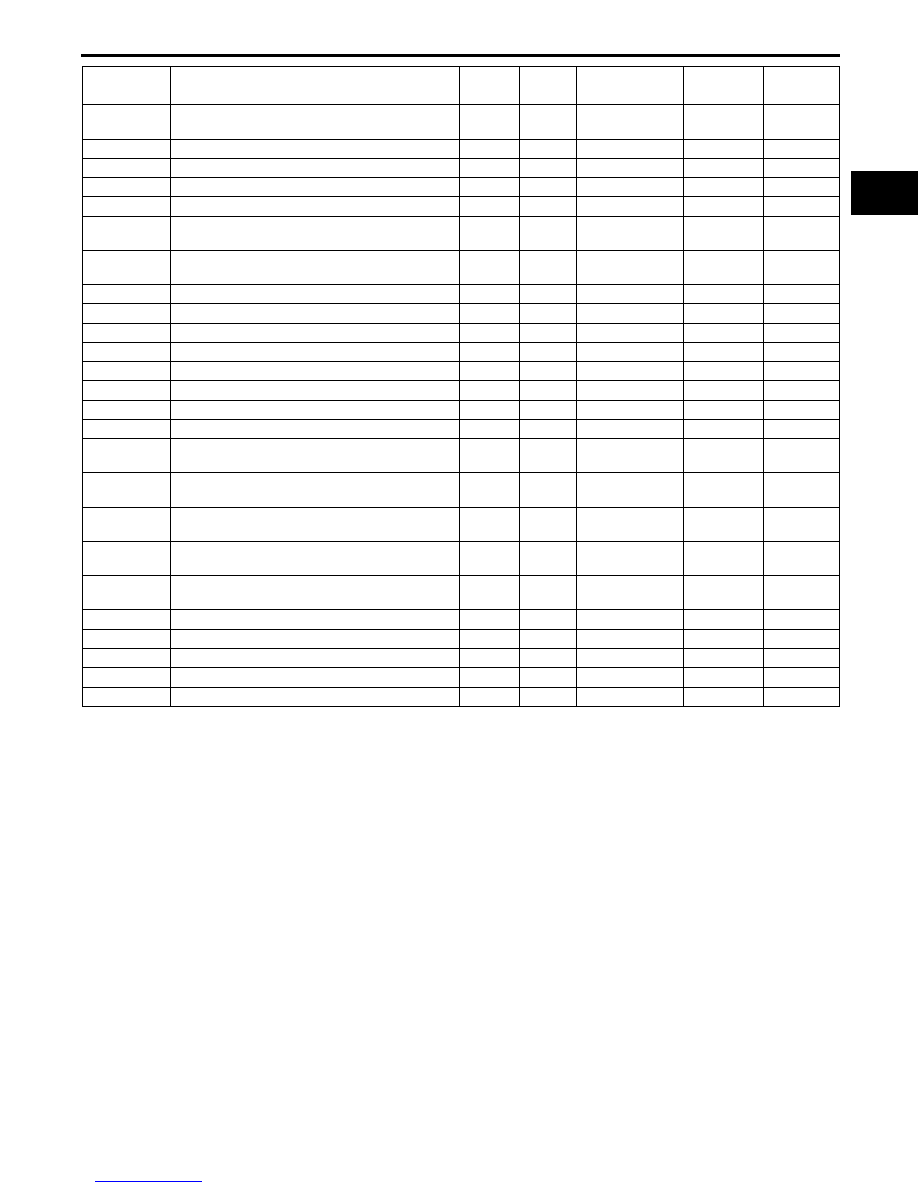

Mazda X-5. Manual - part 8

ON-BOARD DIAGNOSTIC

01–02–9

01–02

*1

: California emission regulation applicable model

*2

: MT

*3

: C: CMDTC self-test, O: KOEO self-test, R: KOER self-test

*4

: With ABS/DSC or MT without ABS/DSC

P2119

Throttle actuator control throttle body range/

performance problem

ON

2

CCM

C, R

×

P2122

APP sensor No.1 circuit low input

ON

1

CCM

C, O, R

×

P2123

APP sensor No.1 circuit high input

ON

1

CCM

C, O, R

×

P2127

APP sensor No.2 circuit low input

ON

1

CCM

C, O, R

×

P2128

APP sensor No.2 circuit high input

ON

1

CCM

C, O, R

×

P2135

TP sensor No.1/No.2 voltage correlation

problem

ON

1

CCM

C, O, R

×

P2138

APP sensor No.1/No.2 voltage correlation

problem

ON

1

CCM

C, O, R

×

P2177

Fuel system too lean at off idle

ON

2

Fuel system

C, R

×

P2178

Fuel system too rich at off idle

ON

2

Fuel system

C, R

×

P2187

Fuel system too lean at idle

ON

2

Fuel system

C, R

×

P2188

Fuel system too rich at idle

ON

2

Fuel system

C, R

×

P2195

Front HO2S signal stuck lean

ON

2

HO2S

C

×

P2196

Front HO2S signal stuck rich

ON

2

HO2S

C

×

P2228

BARO sensor circuit low input

ON

1

CCM

C, O, R

×

P2229

BARO sensor circuit high input

ON

1

CCM

C, O, R

×

P2401

EVAP system leak detection pump motor

circuit low

ON

2

CCM

C, R

×

P2402

EVAP system leak detection pump motor

circuit high

ON

2

CCM

C, R

×

P2404

EVAP system leak detection pump sense

circuit problem

ON

2

CCM

C, R

×

P2405

EVAP system leak detection pump sense

circuit low input

ON

2

CCM

C, R

×

P2407

EVAP system leak detection pump sense

circuit intermittent

ON

2

CCM

C, R

×

P2502

Charging system voltage problem

OFF

1

Other

C, R

×

P2503

Charging system voltage low

OFF

1

Other

C, R

×

P2504

Charging system voltage high

OFF

1

Other

C, R

×

P2507

PCM B+ voltage low

ON

1

CCM

C, O, R

×

P2610

PCM internal engine off timer performance

ON

2

CCM

C

×

DTC No.

Condition

MIL

DC

Monitor item

Self-test

type*

3

Memory

function