Range Rover 2. Electrical Manual - part 9

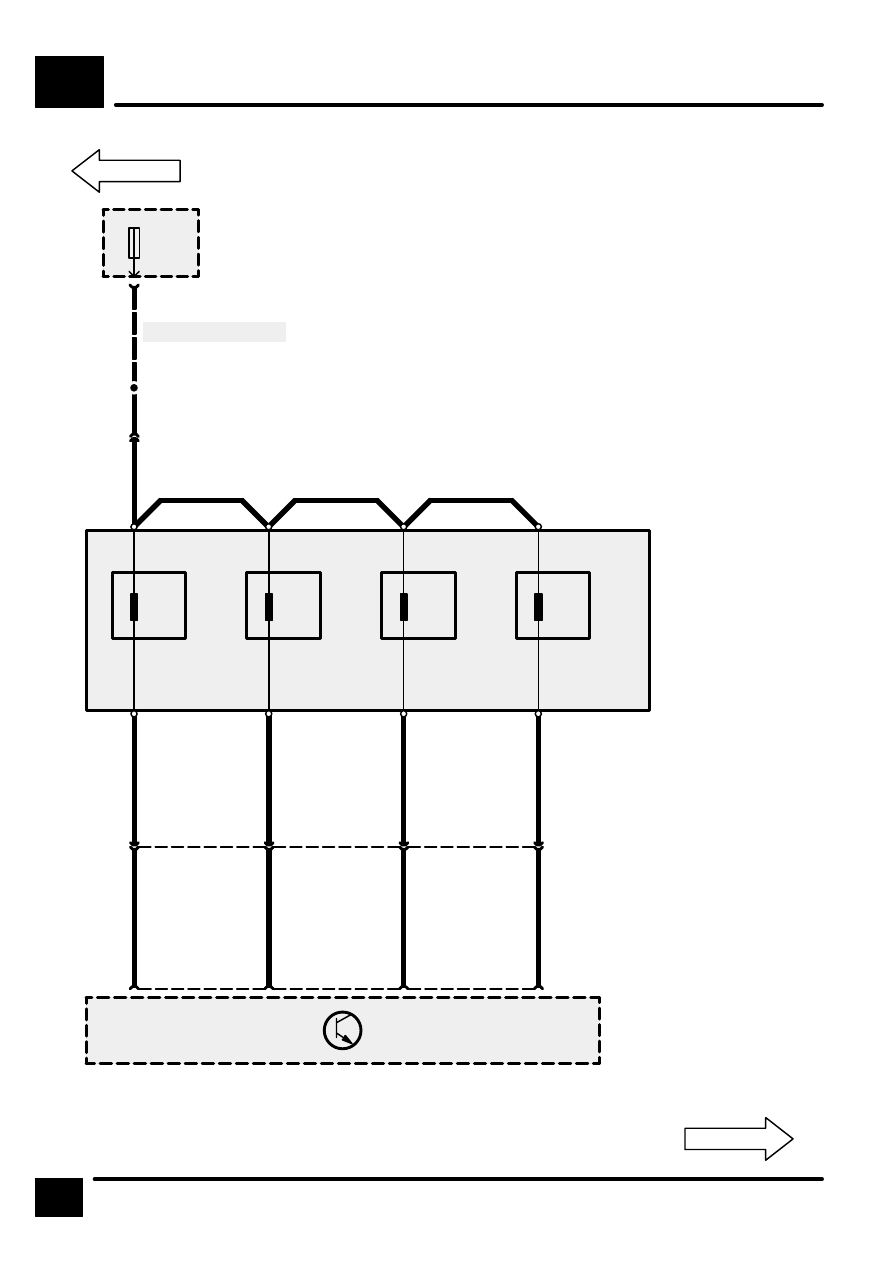

SEQUENTIAL MULTIPORT FUEL INJECTION (SFI–V8)

A1

16

CIRCUIT DIAGRAM

C509

13

14

Z132

Engine Control

Module (ECM)

S509

Z261

Ignition Coils

15

1

3

2

4

C525

1

1&6

2&3

4&7

5&8

5

C525

W

See Fuse Details

P125a

Engine Compart-

ment Fuse Box

15

F 26

20 A

WB

WU

WY

WK

R

R

R

R

U

O

P

G

C508

8