Freelander 1. Manual - part 29

TORQUE WRENCH SETTINGS

06-35

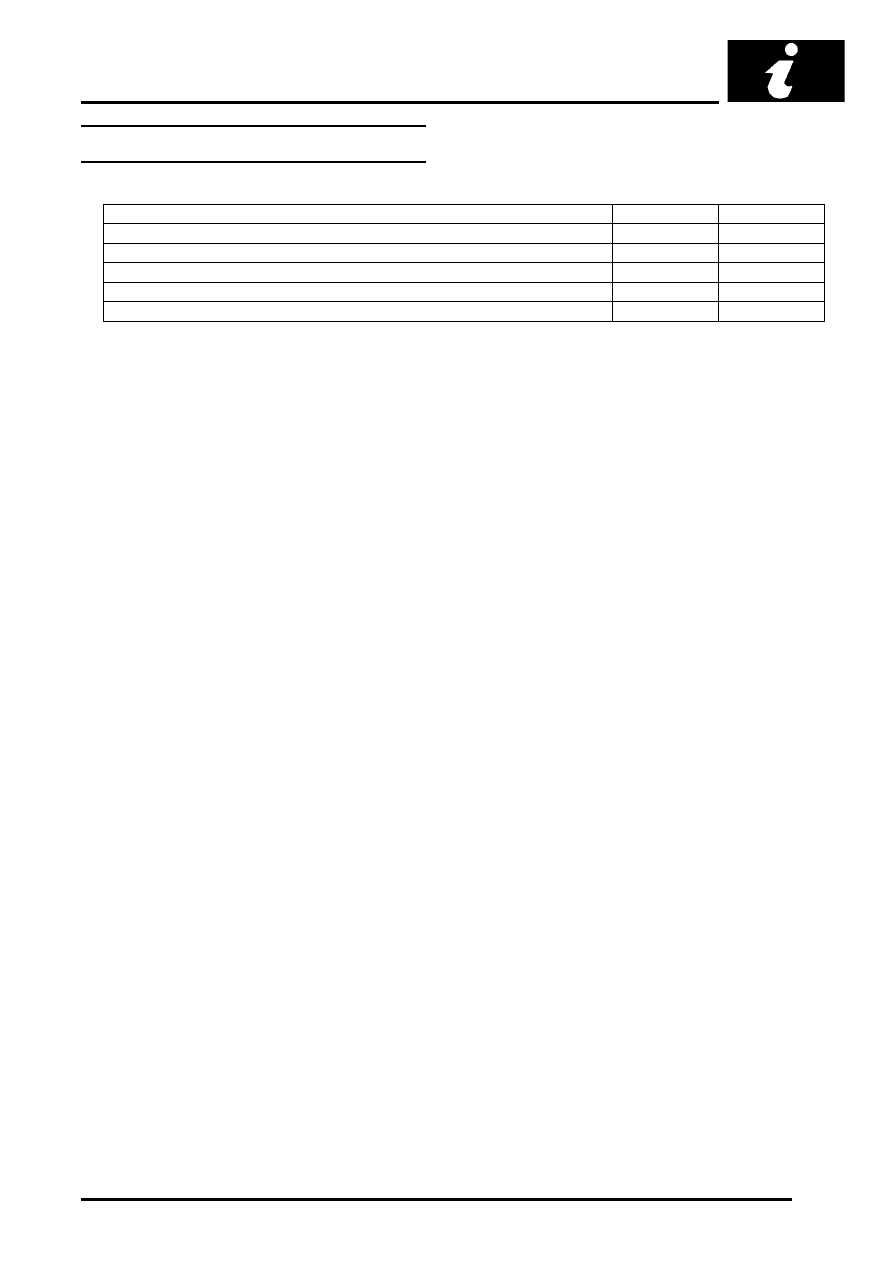

Wipers and Washers

TORQUE DESCRIPTION

METRIC

IMPERIAL

Rear wiper arm nut

13 Nm

10 lbf.ft

Rear wiper motor bolts

5 Nm

3.7 lbf.ft

Rear wiper motor spindle nut

5 Nm

3.7 lbf.ft

Windscreen wiper arm nut

18 Nm

13 lbf.ft

Windscreen wiper motor and linkage to body bolts

5 Nm

3.7 lbf.ft