Infiniti QX56 (JA60). Manual - part 801

RSU-14

< REMOVAL AND INSTALLATION >

REAR SUSPENSION MEMBER

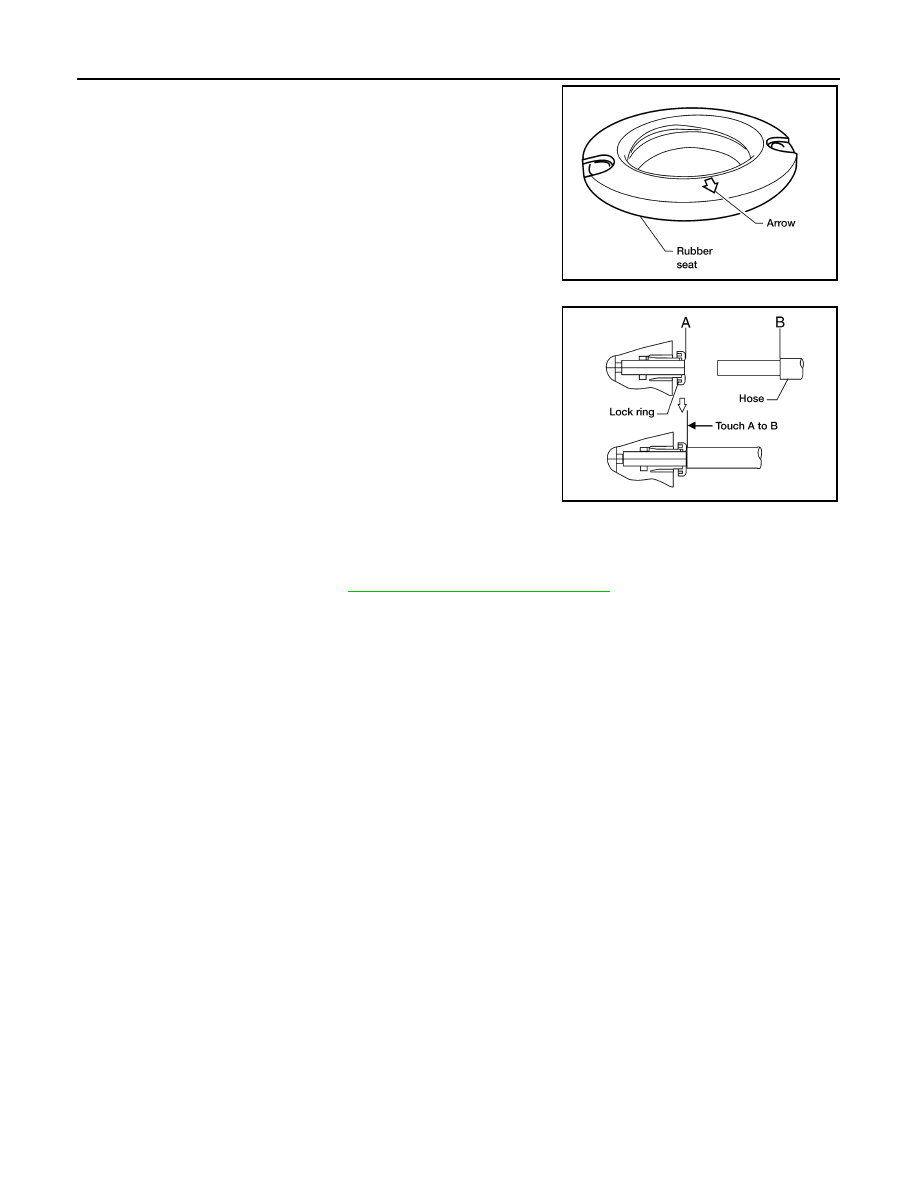

• When installing the upper and lower rubber seats for the rear coil

springs, the arrow embossed on the rubber seats must point out

toward the wheel and tire assembly.

• To connect the rear load leveling air suspension hoses, the lock

ring must be fully seated in the fitting. Insert the hose (B) into the

lock ring (A) until the lock ring (A) is touching the hose (B) as

shown. Pull on the hose to check that it is securely inserted.

• Perform the final tightening of the nuts and bolts for the links (rubber bushing) under unladen condition

(unladen condition means that the fuel tank, engine coolant and lubricants are at the full specification, and

the spare tire, jack, hand tools, and mats are in their designated positions) with the tires on level ground.

• Check the wheel alignment. Refer to

RSU-6, "Wheel Alignment Inspection"

.

LEIA0076E

LEIA0078E