Infiniti QX56 (JA60). Manual - part 685

CHASSIS AND BODY MAINTENANCE

MA-33

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

• If a tire balance machine has adhesion balance weight mode settings and drive-in weight mode setting,

select and adjust a drive-in weight mode suitable for wheels.

1. Set wheel on wheel balancer using the center hole as a guide. Start the tire balance machine.

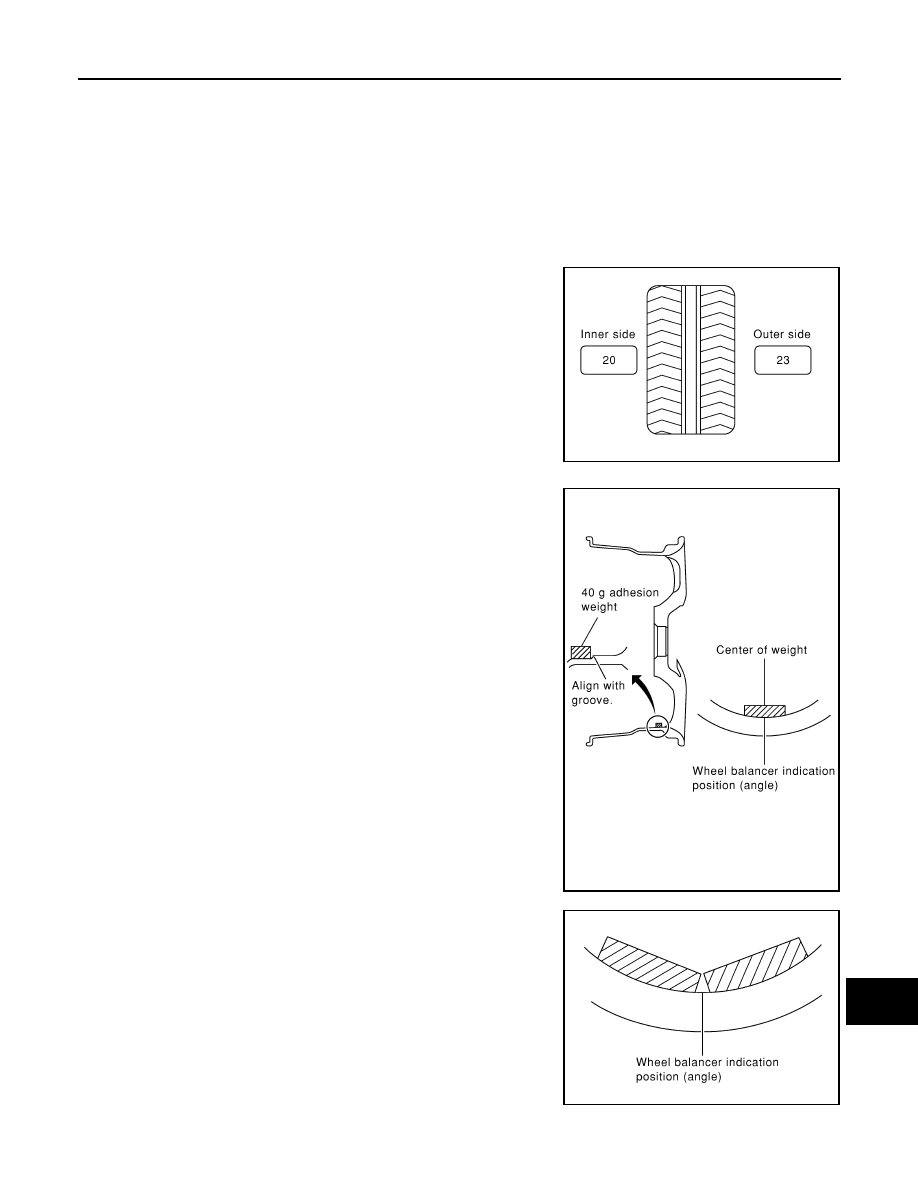

2. When inner and outer imbalance values are shown on the wheel balancer indicator, multiply outer imbal-

ance value by 1.6 to determine balance weight that should be used. Select the outer balance weight with

a value closest to the calculated value and install it to the designated outer position of, or at the desig-

nated angle in relation to the road wheel.

CAUTION:

• Do not install the inner balance weight before installing the outer balance weight.

• Before installing the balance weight, be sure to clean the mating surface of the wheel.

Indicated imbalance value

× 5/3 = balance weight to be installed

Calculation example:

23 g (0.81 oz)

× 5/3 = 38.33 g (1.35 oz) = 40 g (1.41 oz) balance

weight (closer to calculated balance weight value)

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

37.4 g = 35 g (1.23 oz)

37.5 g = 40 g (1.41 oz)

a. Install balance weight in the position shown.

b. When installing balance weight to wheels, set it into the grooved

area on the inner wall of the wheel as shown so that the balance

weight center is aligned with the wheel balancer indication posi-

tion (angle).

CAUTION:

• Always use Genuine NISSAN adhesion balance weights.

• Balance weights are not reusable; always replace with

new ones.

• Do not install more than three sheets of balance weights.

c. If calculated balance weight value exceeds 50 g (1.76 oz), install

two balance weight sheets in line with each other as shown.

CAUTION:

Do not install one balance weight sheet on top of another.

3. Start wheel balancer again.

4. Install drive-in balance weight on inner side of road wheel in the

wheel balancer indication position (angle).

CAUTION:

Do not install more than two balance weights.

5. Start wheel balancer. Make sure that inner and outer residual

imbalance values are 5 g (0.18 oz) each or below.

• If either residual imbalance value exceeds 5 g (0.18 oz),

repeat installation procedures.

SMA054D

WDIA0060E

SMA056D