Infiniti QX56 (JA60). Manual - part 681

ENGINE MAINTENANCE

MA-17

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

• Pull negative-pressure valve to open it and make sure that it closes

completely when released.

• Make sure that there is no dirt or damage on the valve seat of radi-

ator cap negative-pressure valve.

• Make sure that there are no unusualness in the opening and clos-

ing conditions of negative-pressure valve.

ENGINE COOLANT : Changing Engine Coolant

INFOID:0000000005403134

WARNING:

• To avoid being scalded, never change the coolant when the engine is hot.

• Wrap a thick cloth around the cap to carefully remove the cap. First, turn the cap a quarter of a turn

to release any built-up pressure, then push down and turn the cap all the way to remove it.

DRAINING ENGINE COOLANT

1. Turn ignition switch ON and set temperature control lever all the way to HOT position or the highest tem-

perature position. Wait 10 seconds and turn ignition switch OFF.

2. Remove the engine front undercover using power tool.

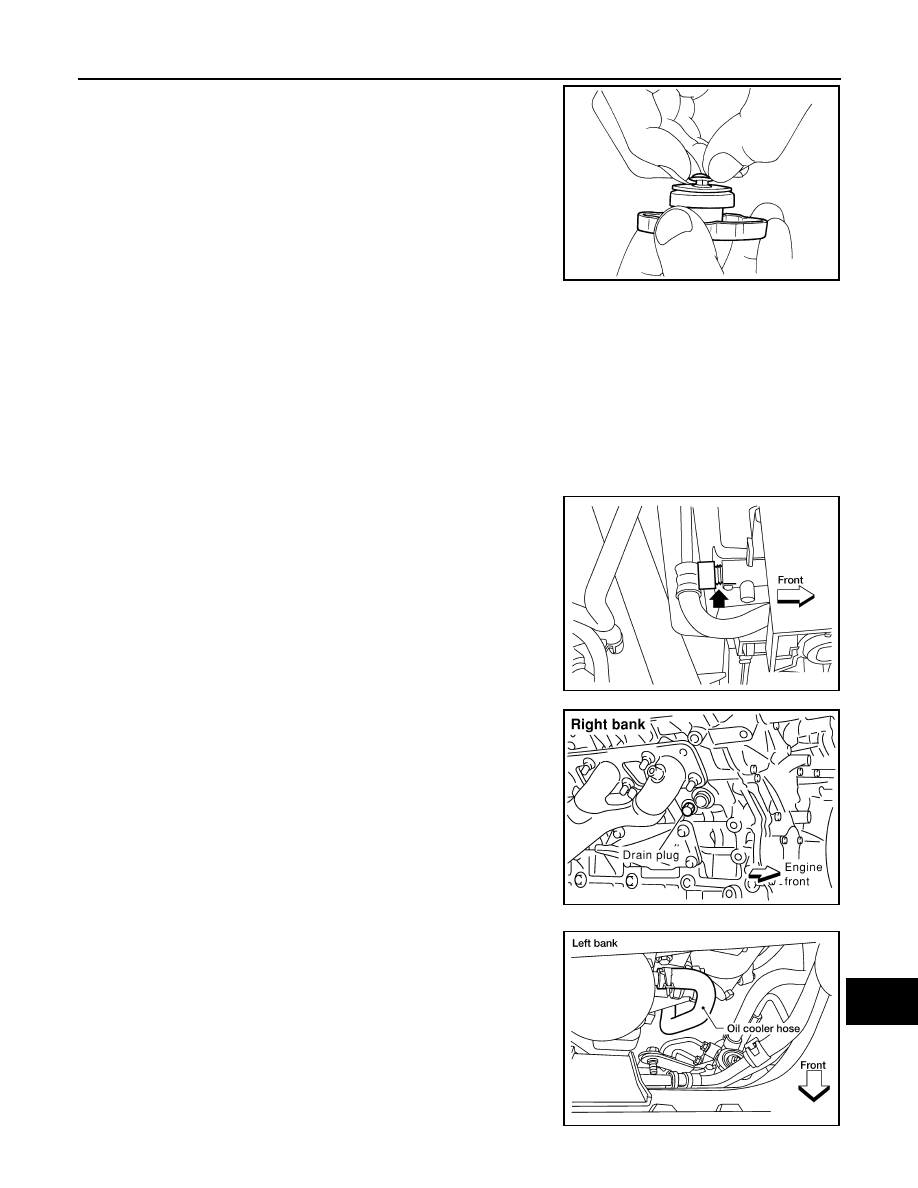

3. Open the radiator drain plug at the bottom of the radiator, and

remove the radiator filler cap. This is the only step required

when partially draining the cooling system (radiator only).

CAUTION:

Do not to allow the coolant to contact the drive belts.

4. When draining all of the coolant in the system for engine

removal or repair, it is necessary to drain the cylinder block.

Remove the RH cylinder block drain plug to drain the right bank

and the oil cooler hose to drain the left bank as shown.

SMA967B

WBIA0391E

PBIC0146E

WBIA0392E