Infiniti QX56 (JA60). Manual - part 478

EM-66

< ON-VEHICLE REPAIR >

OIL SEAL

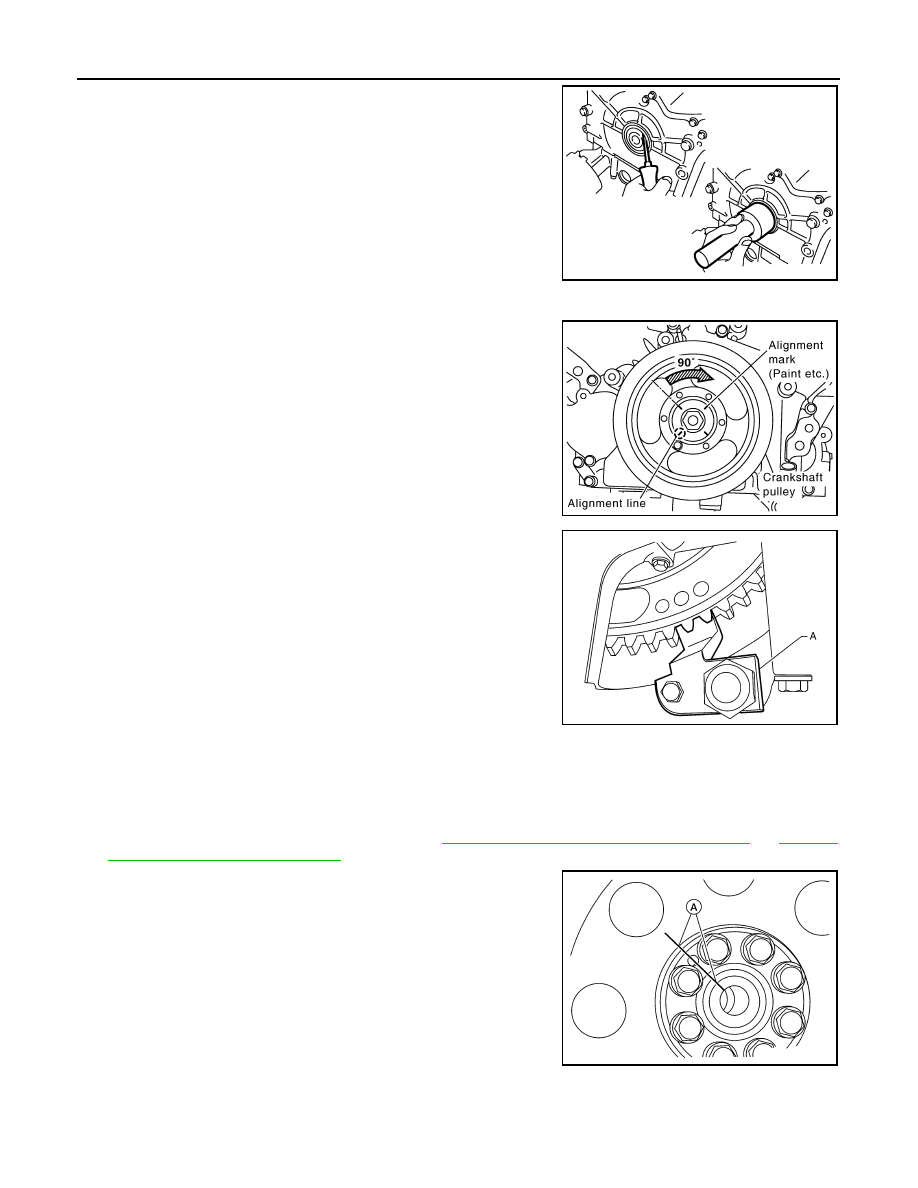

• Press-fit until the height of the front oil seal is level with the

mounting surface using suitable tool.

CAUTION:

• Do not damage front timing chain case and crankshaft.

• Press-fit straight and avoid causing burrs or tilting of the

oil seal.

3. Apply engine oil onto the threaded parts of the crankshaft pulley bolt and seating area.

4. Align the matchmark on the crankshaft pulley bolt flange and the

crankshaft pulley, install crankshaft pulley and tighten bolt to

specifications using Tool.

5. Remove Tool (A).

6. Installation of the remaining components is in the reverse order of removal.

Removal and Installation of Rear Oil Seal

INFOID:0000000005149006

REMOVAL

1. Remove the transmission assembly. Refer to

TM-186, "Removal and Installation (2WD)"

"Removal and Installation (4WD)"

2. Before removing the drive plate, put a match mark (A) on the

crankshaft and drive plate for alignment during installation

3. Remove the drive plate.

PBIC2931E

Crankshaft pulley bolt torque

Step 1

: 93.1 N·m (9.5 kg-m, 69 ft-lb)

Step 2

: additional 90

° (angle tightening)

Tool number

: KV10112100 (BT-8653-A)

KBIA2519E

Tool number

: — (J-47245)

LBIA0455E

ALBIA0522ZZ