Infiniti QX56 (JA60). Manual - part 395

EC-232

< COMPONENT DIAGNOSIS >

[VK56DE]

P0444, P0445 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID

VALVE

DTC Confirmation Procedure

INFOID:0000000005149249

NOTE:

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next step.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm battery voltage is more than 11 V at idle.

1. Start engine and let it idle for at least 13 seconds.

2. Check 1st trip DTC.

3. If 1st trip DTC is detected, go to

Diagnosis Procedure

INFOID:0000000005149250

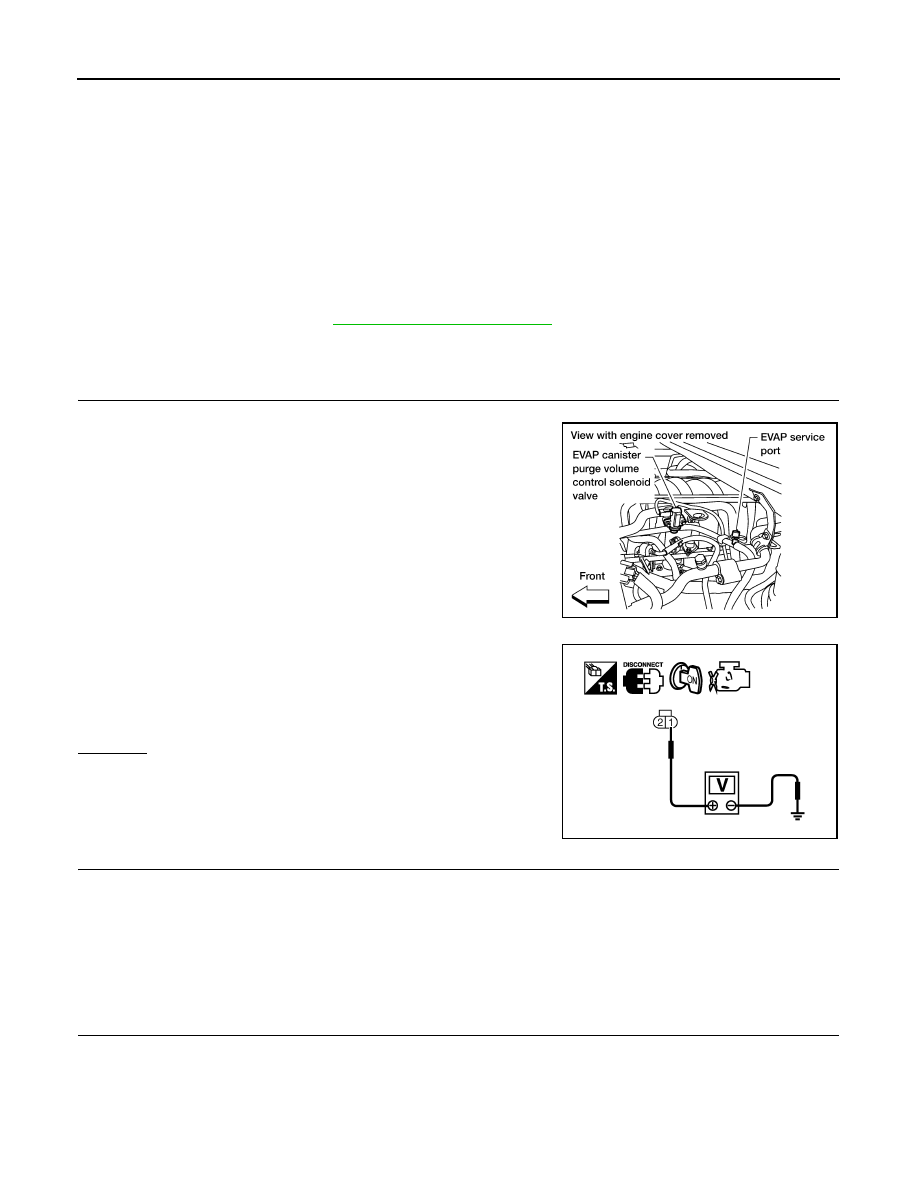

1.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect EVAP canister purge volume control solenoid valve

harness connector.

3. Turn ignition switch ON.

4. Check voltage between EVAP canister purge volume control

solenoid valve terminal 1 and ground with CONSULT-III or

tester.

OK or NG

OK

>> GO TO 3.

NG

>> GO TO 2.

2.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

• Harness for open or short between EVAP canister purge volume control solenoid valve and IPDM E/R

• Harness for open or short between EVAP canister purge volume control solenoid valve and ECM

>> Repair harness or connectors.

3.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT

FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 45 and EVAP canister purge volume control solenoid

valve terminal 2. Refer to Wiring Diagram.

BBIA0366E

Voltage: Battery voltage

PBIB2245E

Continuity should exist.