Infiniti QX56 (JA60). Manual - part 385

EC-192

< COMPONENT DIAGNOSIS >

[VK56DE]

P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308 MISFIRE

P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308 MIS-

FIRE

On Board Diagnosis Logic

INFOID:0000000005149211

When a misfire occurs, engine speed will fluctuate. If the engine speed fluctuates enough to cause the crank-

shaft position (CKP) sensor (POS) signal to vary, ECM can determine that a misfire is occurring.

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage)

On the 1st trip, when a misfire condition occurs that can damage the three way catalyst (TWC) due to

overheating, the MIL will blink.

When a misfire condition occurs, the ECM monitors the CKP sensor signal every 200 engine revolutions

for a change.

When the misfire condition decreases to a level that will not damage the TWC, the MIL will turn off.

If another misfire condition occurs that can damage the TWC on a second trip, the MIL will blink.

When the misfire condition decreases to a level that will not damage the TWC, the MIL will remain on.

If another misfire condition occurs that can damage the TWC, the MIL will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration)

For misfire conditions that will not damage the TWC (but will affect vehicle emissions), the MIL will only

light when the misfire is detected on a second trip. During this condition, the ECM monitors the CKP sen-

sor signal every 1,000 engine revolutions.

A misfire malfunction can be detected on any one cylinder or on multiple cylinders.

DTC Confirmation Procedure

INFOID:0000000005149212

CAUTION:

Always drive vehicle in safe manner according to traffic conditions and obey all traffic laws when driv-

ing.

1. If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next step.

a. Turn ignition switch OFF and wait at least 10 seconds.

b. Turn ignition switch ON.

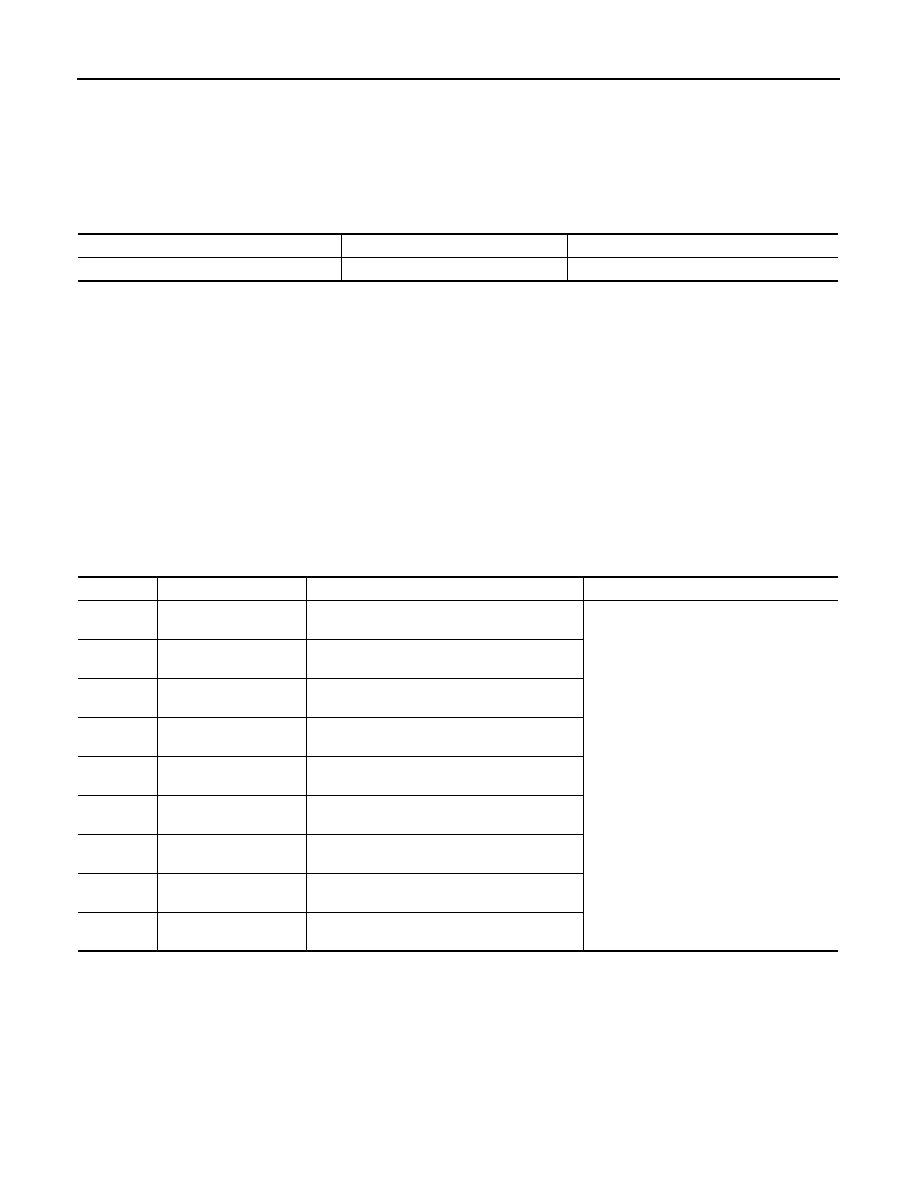

Sensor

Input signal to ECM

ECM function

Crankshaft position sensor (POS)

Engine speed

On board diagnosis of misfire

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0300

0300

Multiple cylinder misfire

detected

Multiple cylinder misfire.

• Improper spark plug

• Insufficient compression

• Incorrect fuel pressure

• The injector circuit is open or shorted

• Fuel injector

• Intake air leak

• The ignition signal circuit is open or short-

ed

• Lack of fuel

• Signal plate

• Air fuel ratio (A/F) sensor 1

• Incorrect PCV hose connection

P0301

0301

No.1 cylinder misfire de-

tected

No. 1 cylinder misfires.

P0302

0302

No. 2 cylinder misfire

detected

No. 2 cylinder misfires.

P0303

0303

No. 3 cylinder misfire

detected

No. 3 cylinder misfires.

P0304

0304

No. 4 cylinder misfire

detected

No. 4 cylinder misfires.

P0305

0305

No. 5 cylinder misfire

detected

No. 5 cylinder misfires.

P0306

0306

No. 6 cylinder misfire

detected

No. 6 cylinder misfires.

P0307

0307

No. 7 cylinder misfire

detected

No. 7 cylinder misfires.

P0308

0308

No. 8 cylinder misfire

detected

No. 8 cylinder misfires.