Infiniti QX56 (JA60). Manual - part 364

EC-108

< COMPONENT DIAGNOSIS >

[VK56DE]

P0101 MAF SENSOR

OK

>> GO TO 11.

NG

>> Replace mass air flow sensor.

11.

CHECK INTERMITTENT INCIDENT

GI-35, "How to Check Terminal"

and

GI-38, "Intermittent Incident"

>> INSPECTION END

Component Inspection

INFOID:0000000005149115

MASS AIR FLOW SENSOR

With CONSULT-III

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Connect CONSULT-III and select “DATA MONITOR” mode.

4. Select “MAS A/F SE-B1” and check indication under the following conditions.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

5. If the voltage is out of specification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following.

• Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system parts

b. If NG, repair or replace malfunctioning part and perform step 2 to 4 again.

If OK, go to next step.

6. Turn ignition switch OFF.

7. Disconnect mass air flow sensor harness connector and reconnect it again.

8. Perform step 2 to 4 again.

9. If NG, clean or replace mass air flow sensor.

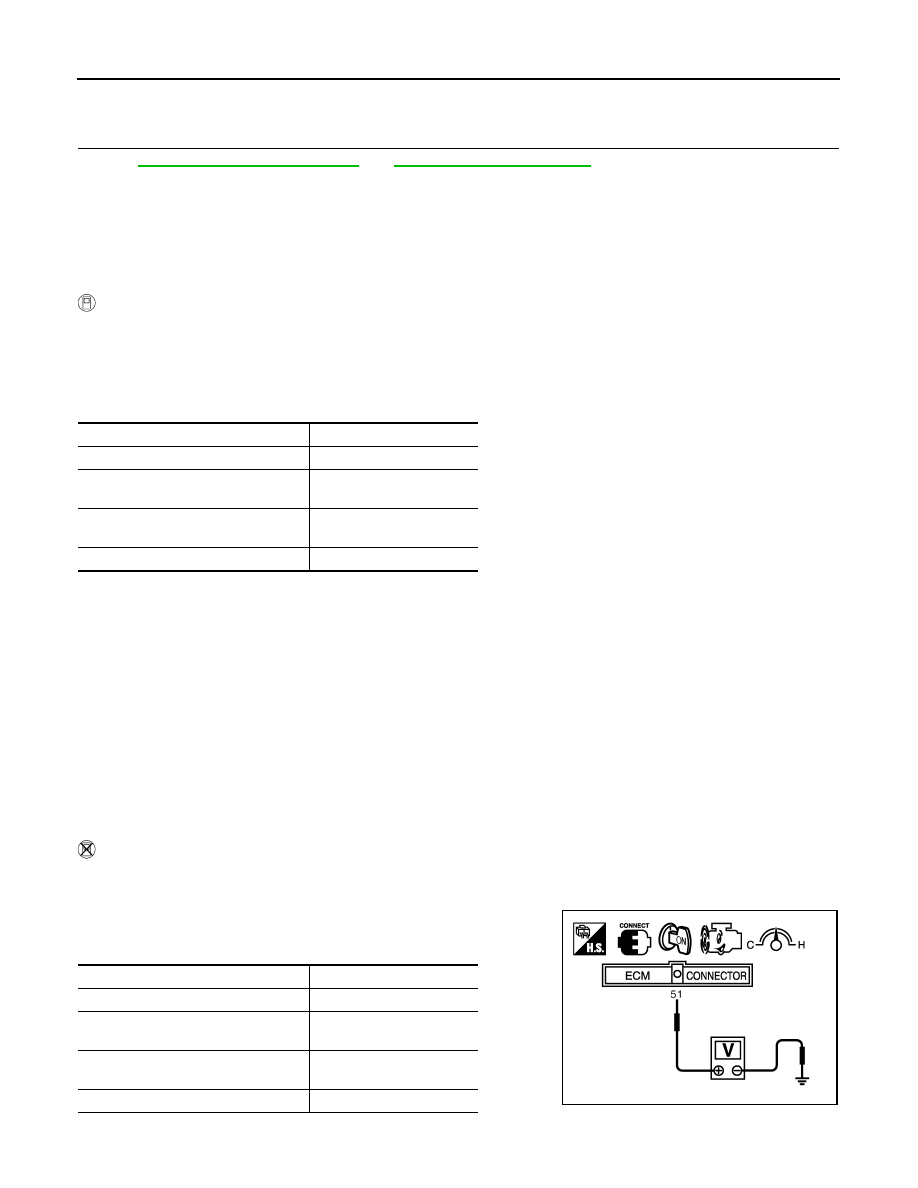

Without CONSULT-III

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminal 51 (Mass air flow sensor

signal) and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Condition

MAS A/F SE-B1 (V)

Ignition switch ON (Engine stopped.)

Approx. 0.4

Idle (Engine is warmed-up to normal

operating temperature.)

0.9 - 1.3

2,500 rpm (Engine is warmed-up to

normal operating temperature.)

1.7 - 2.1

Idle to about 4,000 rpm

0.9 - 1.3 to Approx. 2.4*

Condition

MAS A/F SE-B1 (V)

Ignition switch ON (Engine stopped.)

Approx. 0.4

Idle (Engine is warmed-up to normal

operating temperature.)

0.9 - 1.3

2,500 rpm (Engine is warmed-up to

normal operating temperature.)

1.7 - 2.1

Idle to about 4,000 rpm

0.9 - 1.3 to Approx. 2.4*

PBIB1106E