Infiniti QX56 (JA60). Manual - part 332

REAR FINAL DRIVE

DLN-251

< REMOVAL AND INSTALLATION >

[REAR FINAL DRIVE: R230]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

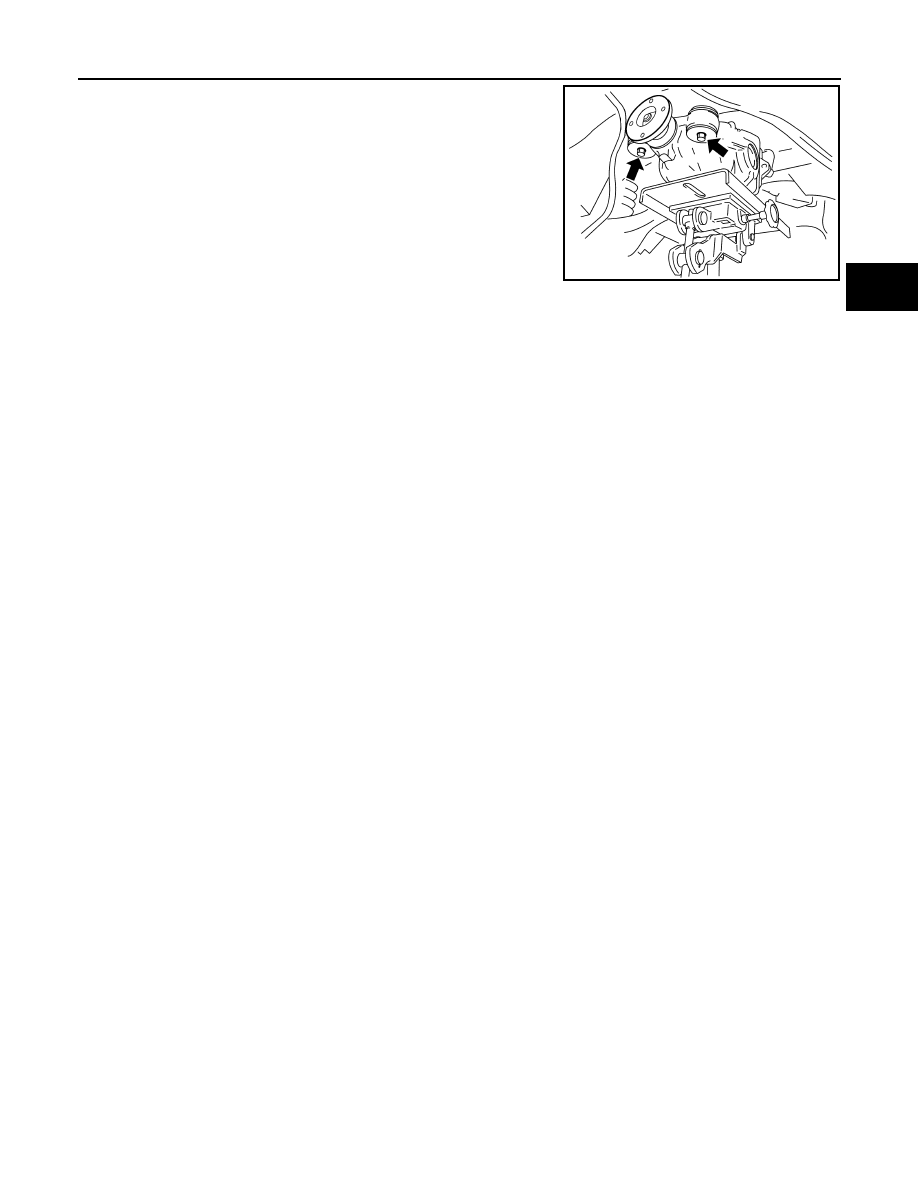

7. Place a suitable jack under the rear final drive assembly.

CAUTION:

Do not place the jack on the carrier cover.

8. Remove the nuts and bolts and remove the rear final drive

assembly.

CAUTION:

Secure rear final drive assembly to the jack while removing

it.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• When installing the breather hose make sure the painted marking on the metal end of breather hose

is to the front of the vehicle and there are no pinched or restricted areas on the breather hose

caused by folding or bending when installing it.

• When installing the breather hose insert the plastic end of the breather hose into the hole in the sus-

pension member.

WDIA0117E