Infiniti QX56 (JA60). Manual - part 149

NORMAL OPERATING CONDITION

BRC-109

< SYMPTOM DIAGNOSIS >

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

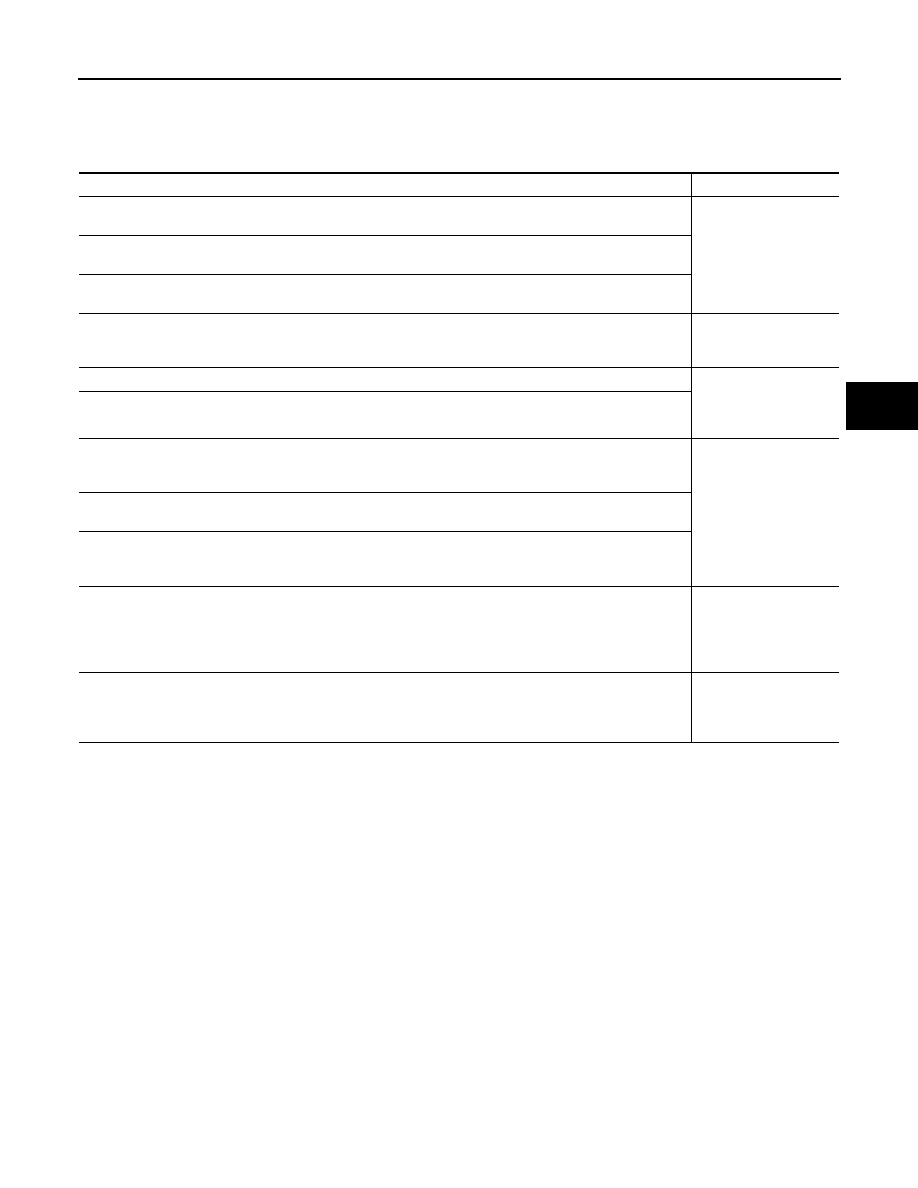

NORMAL OPERATING CONDITION

Description

INFOID:0000000005148092

Symptom

Result

Slight vibrations are felt on the brake pedal and the operation noises occur, when VDC, TCS or ABS is acti-

vated.

This is a normal condi-

tion due to the VDC,

TCS or ABS activation.

Stopping distance is longer than that of vehicles without ABS when the vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

The brake pedal moves and generates noises, when TCS or VDC is activated due to rapid acceleration or

sharp turn.

The brake pedal vibrates and motor operation noises occur from the engine room, after the engine starts and

just after the vehicle starts.

This is normal, and it is

caused by the ABS op-

eration check.

Depending on the road conditions, the driver may experience a sluggish feel.

This is normal, because

TCS places the highest

priority on the optimum

traction (stability).

TCS may activate momentarily if wheel speed changes when driving over location where friction coefficient

varies, when downshifting, or when fully depressing accelerator pedal.

The ABS warning lamp, VDC OFF indicator lamp and SLIP indicator lamp may turn ON when the vehicle is

subject to strong shaking or large vibration, such as when the vehicle is rotating on a turntable or located on

a ship while the engine is running.

In this case, restart the

engine on a normal

road. If the normal con-

dition is restored, there

is no malfunction. At

that time, erase the self-

diagnosis memory.

VDC may not operate normally or the ABS warning lamp, VDC OFF indicator lamp, and SLIP indicator lamp

may illuminate, when running on a special road that is extremely slanted (e.g. bank in a circuit course).

A malfunction may occur in the yaw rate/side/decel G sensor system, when the vehicle turns sharply, such

as during a spin turn, axle turn, or drift driving, while the VDC function is off (VDC OFF indicator lamp illumi-

nated).

The vehicle speed will not increase even though the accelerator pedal is depressed, when inspecting the

speedometer on a 2-wheel chassis dynamometer.

Normal (Deactivate the

VDC/TCS function be-

fore performing an in-

spection on a chassis

dynamometer.)

VDC OFF indicator lamp and SLIP indicator lamp may simultaneously turn on when low tire pressure warn-

ing lamp turns on.

This is not a VDC sys-

tem error but results

from characteristic

change of tire.