Infiniti QX56 (JA60). Manual - part 115

BR-20

< ON-VEHICLE REPAIR >

BRAKE PEDAL

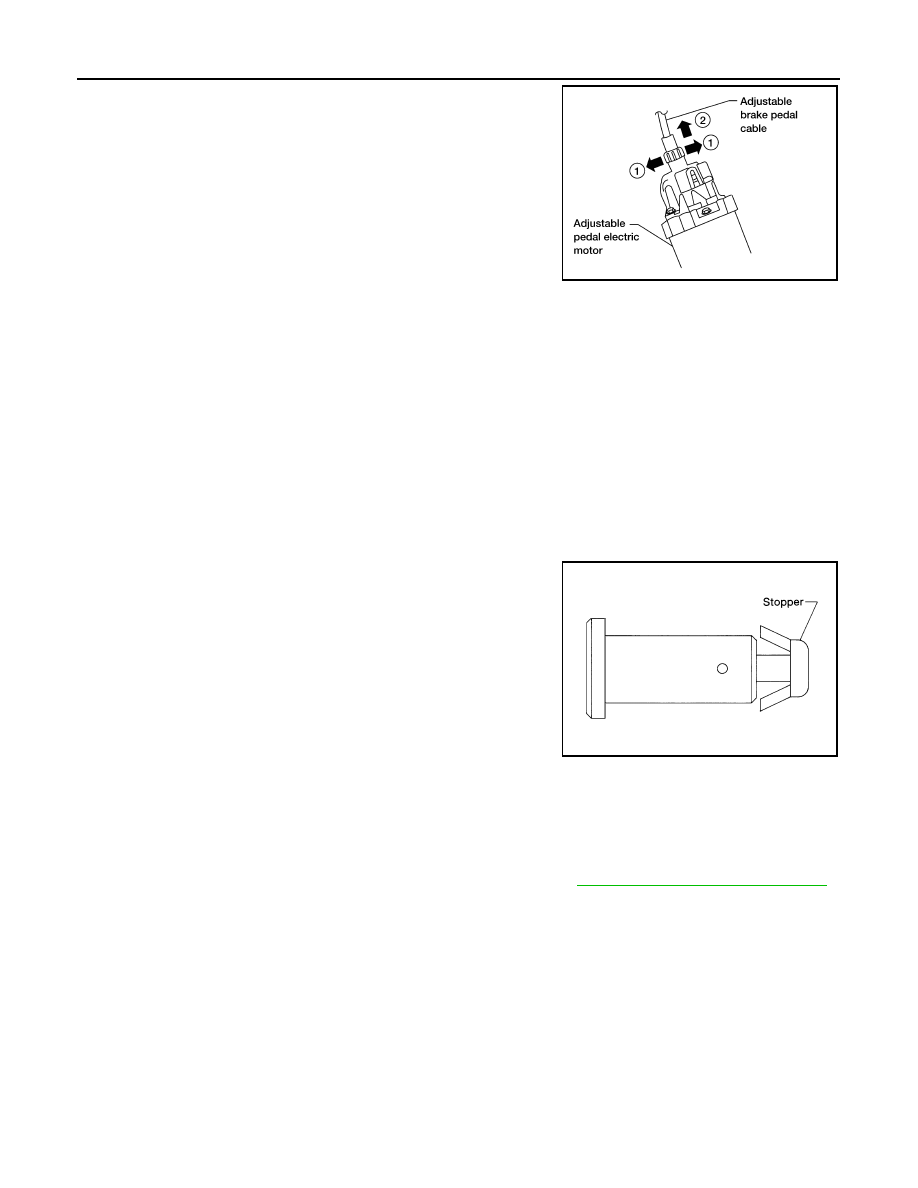

3. Disconnect the adjustable brake pedal cable from the adjustable

pedal electric motor.

• Unlock (1) then pull (2) the adjustable brake pedal cable to dis-

connect it from the adjustable pedal electric motor as shown.

4. Remove snap pin and clevis pin from the clevis of brake booster.

5. Remove brake pedal assembly nuts and remove the brake pedal assembly.

• Temporarily install the brake pedal assembly nuts by hand to support the brake booster.

WARNING:

Do not bend the brake tubing.

CAUTION:

• Before removal and installation, the accelerator and brake pedals must be in the forward most

position (closest to the floor). This is to align the base position of the accelerator and brake ped-

als.

• Do not disassemble the brake pedal adjusting mechanism.

• Avoid damage from dropping the brake pedal assembly during handling.

• Keep the brake pedal assembly away from water.

INSPECTION AFTER REMOVAL

Check the brake pedal assembly for the following items:

• Crack or deformation of clevis pin stopper

• Clevis pin deformation

• Crack of any welded portion of the brake pedal assembly

• Brake pedal bend or deformation

INSTALLATION

Installation is in the reverse order of removal.

• Check the brake pedal for smooth operation. There should be no binding or sticking when applying or

releasing the brake pedal.

• Check the brake pedal adjustable feature for smooth operation. There should be no binding or sticking when

adjusting the brake pedal forward or backward.

• After installing the brake pedal assembly, be sure to adjust it. Refer to

BR-15, "Inspection and Adjustment"

LBIA0374E

SBR997