Infiniti QX56 (Z62). Manual - part 750

LIFTING POINT

GI-33

< PRECAUTION >

C

D

E

F

G

H

I

J

K

L

M

B

GI

N

O

P

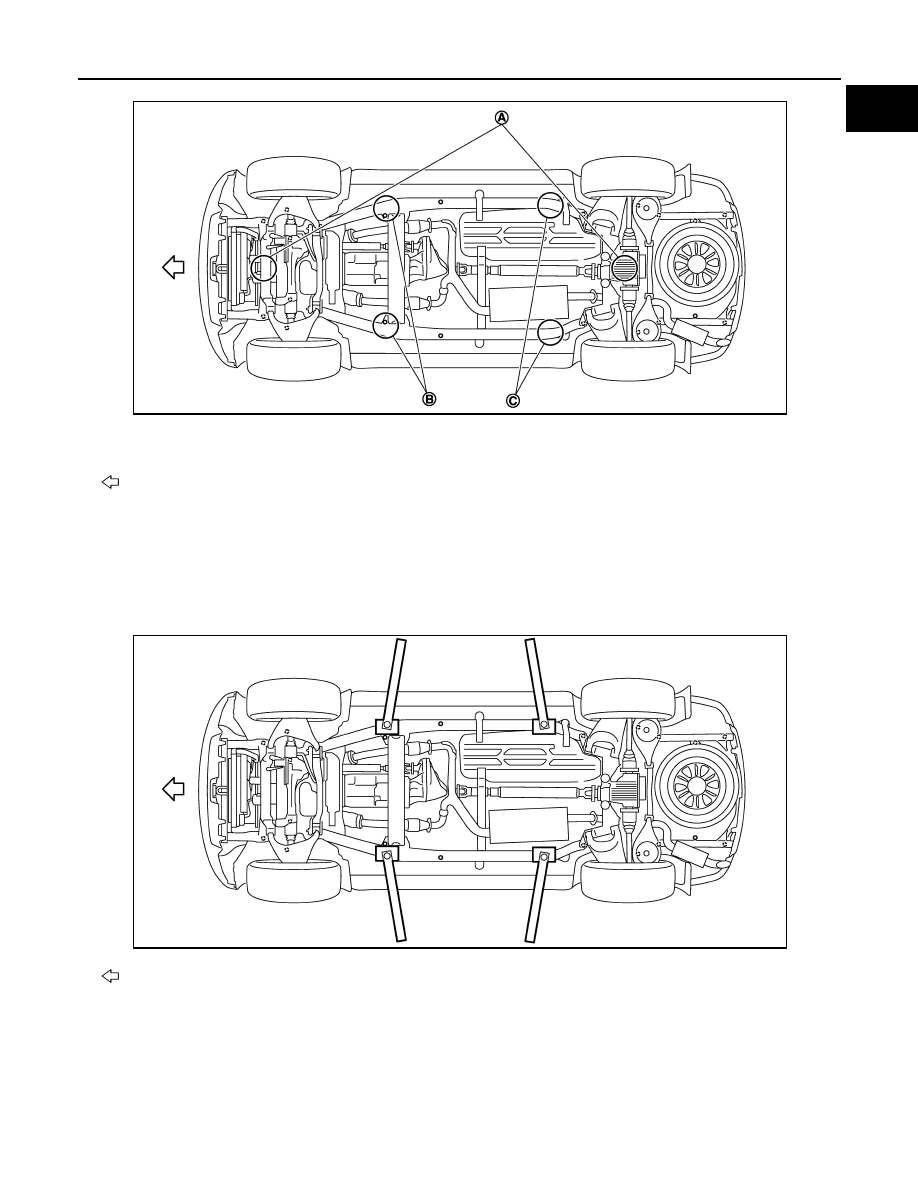

2-Pole Lift

INFOID:0000000006280879

WARNING:

• When lifting the vehicle, open the lift arms as wide as possible and ensure that the front and rear of

the vehicle are well balanced.

• When setting the lift arm, never allow the arm to contact the brake tubes, brake cable, or fuel lines.

A

: Garage jack point

B

: Safety stand point

: Vehicle front

JMAIA0252ZZ

: Vehicle front

JMAIA0253ZZ