Infiniti QX56 (Z62). Manual - part 643

EM-12

< BASIC INSPECTION >

CAMSHAFT VALVE CLEARANCE

BASIC INSPECTION

CAMSHAFT VALVE CLEARANCE

Inspection

INFOID:0000000006289520

INSPECTION

Check valve clearance if applicable to the following cases:

Intake side:

• At the removal and installation of VVEL ladder assembly or valve-related parts, or at the occurrence of mal-

function (poor starting, idle malfunction, unusual noise) due to aged deterioration in valve clearance.

CAUTION:

Valve clearance check on the intake side is not required after replacing the VVEL ladder assembly &

cylinder head assembly with a new one. (Install new VVEL ladder assembly & cylinder head assembly

in factory-shipped condition because it is factory-adjusted and inspected.)

NOTE:

VVEL ladder assembly cannot be replaced as a single part, because it is machined together with cylinder

head assembly.

Exhaust side:

• At the removal, installation, and replacement of exhaust camshaft or valve-related parts, or at the occur-

rence of malfunction (poor starting, idle malfunction, unusual noise) due to aged deterioration in valve clear-

ance.

1.

Remove VVEL actuator motor assembly. Refer to

EM-36, "Removal and Installation"

2.

Remove rocker covers (bank 1 and bank 2). Refer to

EM-33, "Removal and Installation"

3.

Remove VVEL actuator housing assembly. Refer to

EM-36, "Removal and Installation"

4.

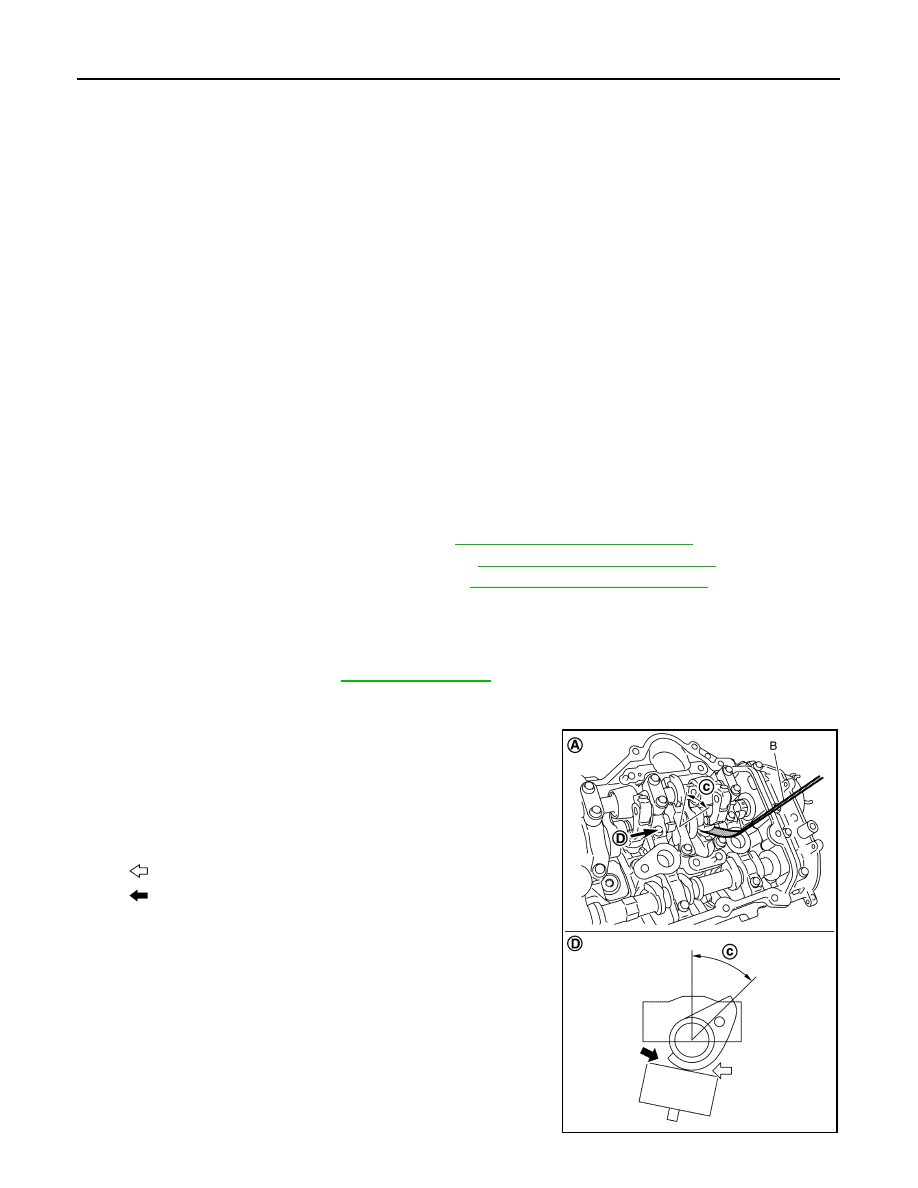

Measure the valve clearance as per the following:

• Use the feeler gauge (commercial service tool) of curved-tip. This allows the feeler gauge to access the

clearance between camshaft (drive shaft) nose and valve lifter with ease.

NOTE:

Be sure to note the following points when measuring valve clearance on the intake side.

• Before measuring, check that the position of drive shaft nose

is within the angle shown in the figure.

• Refer to the figure for the insertion direction of the feeler

gauge since the direction depends on the bank.

Valve clearance

: Refer to

.

A

: Bank 2

B

: Feeler gauge (commercial service tool)

c

: 45 degrees (drive shaft nose angle)

D

: View D

: Insertion direction of feeler gauge on the bank 2

: Insertion direction of feeler gauge on the bank 1

JPBIA3485ZZ