Infiniti QX56 (Z62). Manual - part 569

EC-254

< DTC/CIRCUIT DIAGNOSIS >

[VK56VD]

P0138, P0158 HO2S2

11.

CHECK HEATED OXYGEN SENSOR 2

EC-254, "Component Inspection (HO2 sensor 2)"

.

Is the inspection result normal?

YES

>> GO TO 13.

NO

>> GO TO 12.

12.

REPLACE HEATED OXYGEN SENSOR 2

Replace malfunctioning heated oxygen sensor 2. Refer to

CAUTION:

• Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor Thread

Cleaner [commercial service tool (J-43897-18 or J-43897-12)] and approved anti-seize lubricant

(commercial service tool).

>> INSPECTION END

13.

CHECK INTERMITTENT INCIDENT

GI-40, "Intermittent Incident"

>> INSPECTION END

Component Inspection (HO2 sensor 2)

INFOID:0000000006217820

1.

INSPECTION START

Will CONSULT-III be used?

Will CONSULT-III be used?

YES

>> GO TO 2.

NO

>> GO TO 3.

2.

CHECK HEATED OXYGEN SENSOR 2

WITH CONSULT-III

1.

Start engine and warm it up to the normal operating temperature.

2.

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

3.

Let engine idle for 1 minute.

4.

Select “FUEL INJECTION” in “ACTIVE TEST” mode, and select “HO2S2 (B1)/(B2)” as the monitor item

with CONSULT-III.

5.

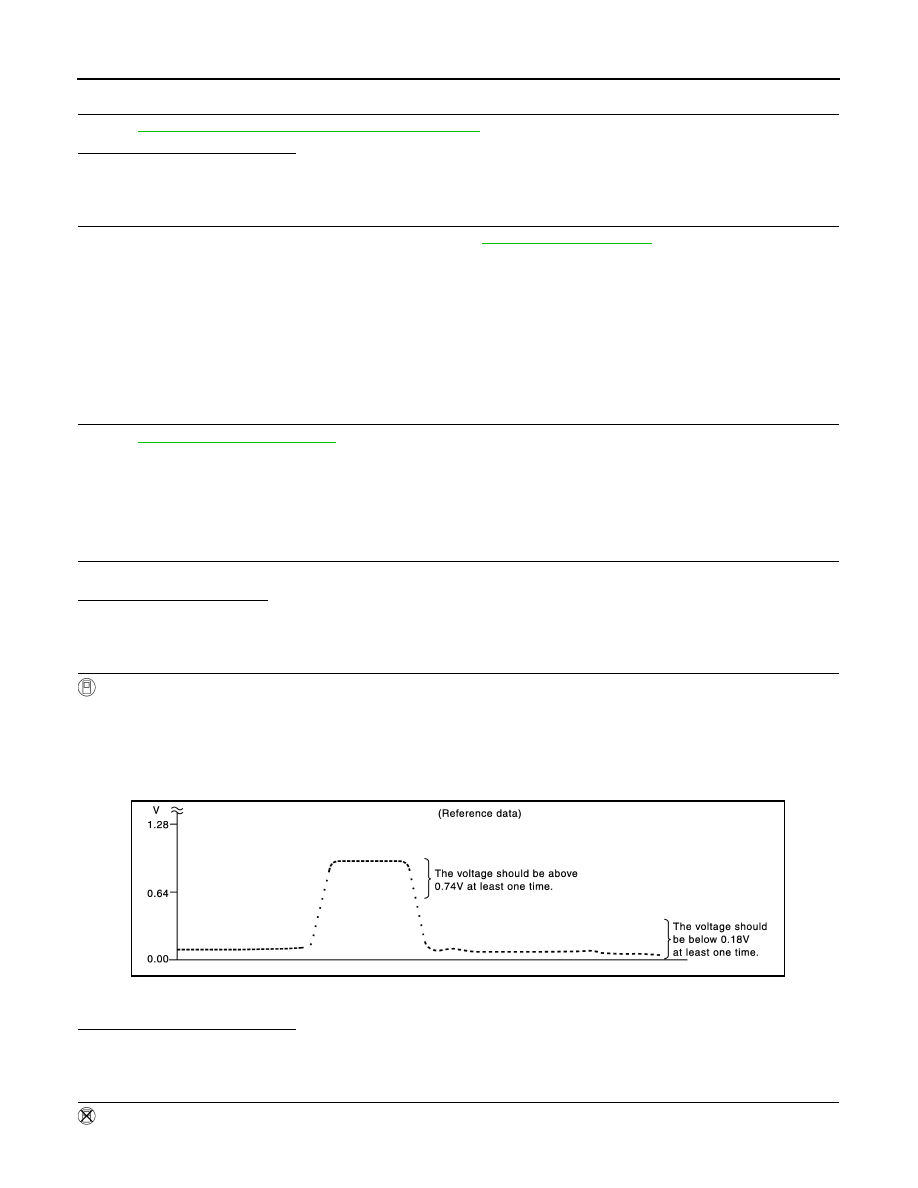

Check “HO2S2 (B1)/(B2)” at idle speed when adjusting “FUEL INJECTION” to

±

25%.

“HO2S2 (B1)/(B2)” should be above 0.74 V at least once when the “FUEL INJECTION” is +25%.

“HO2S2 (B1)/(B2)” should be below 0.18 V at least once when the “FUEL INJECTION” is

−

25%.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 6.

3.

CHECK HEATED OXYGEN SENSOR 2-I

WITHOUT CONSULT-III

1.

Start engine and warm it up to the normal operating temperature.

JMBIA1573GB