Infiniti QX56 (Z62). Manual - part 502

DLN-208

< UNIT DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R230]

DIFFERENTIAL ASSEMBLY

b.

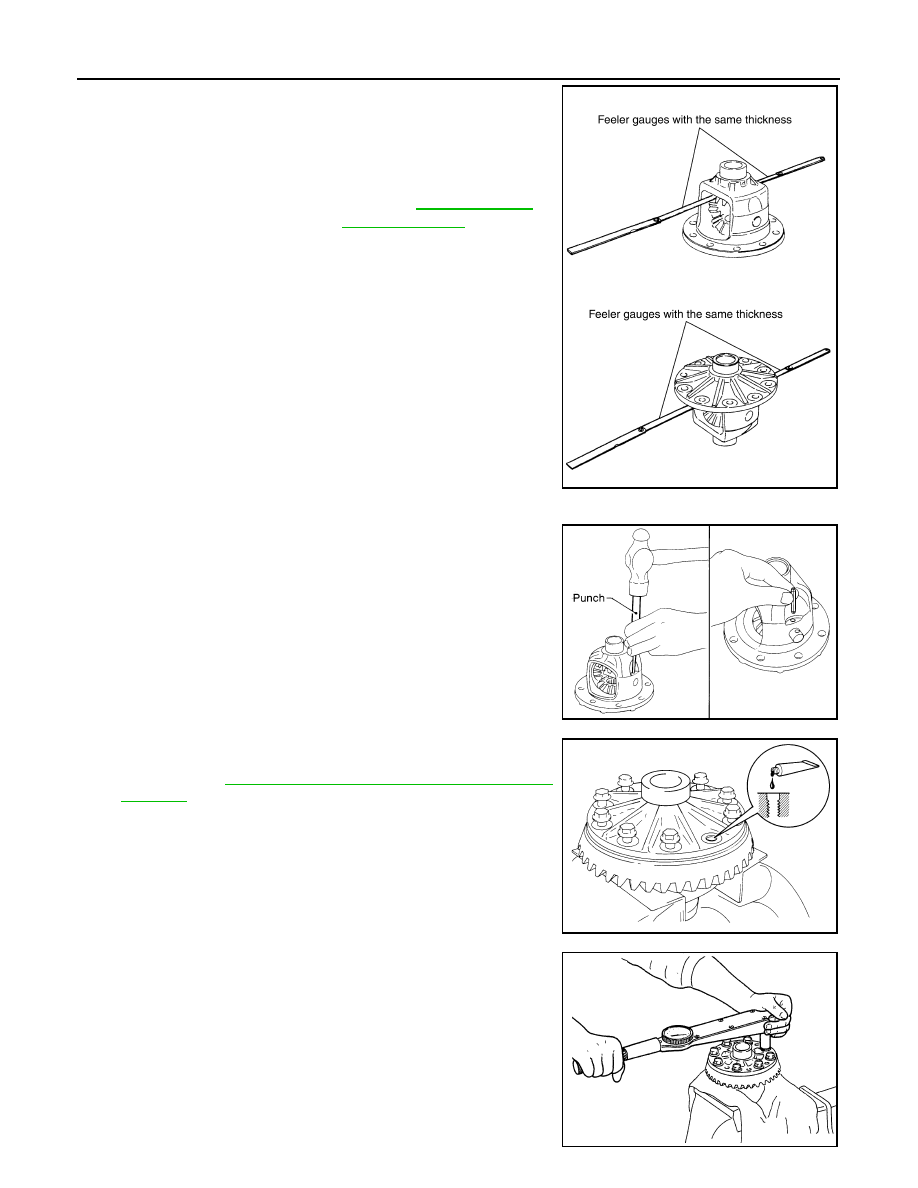

Using feeler gauge, measure the clearance between side gear

back and differential case at 3 different points, while rotating

side gear. Average the 3 readings, and then measure the clear-

ance of the other side as well.

CAUTION:

To prevent side gear from tilting, insert feeler gauges with

the same thickness from both sides.

c.

If the back clearance is outside the specification, use a thicker/

thinner side gear thrust washer to adjust. For selecting thrust

washer, refer to the latest parts information.

CAUTION:

Select a side gear thrust washer for right and left individu-

ally.

6.

Drive a lock pin into pinion mate shaft, using a punch.

Make sure lock pin is flush with differential case.

CAUTION:

Never reuse lock pin.

7.

Apply thread locking sealant into the thread hole of drive gear.

• Use Genuine High Strength Thread Locking Sealant or equiv-

alent. Refer to

GI-22, "Recommended Chemical Products and

.

CAUTION:

Clean and degrease drive gear back and threaded holes

sufficiently.

8.

Install drive gear to differential case.

CAUTION:

Align the matching marks of differential case and drive

gear.

9.

Tighten the mounting bolts with the following procedure.

CAUTION:

Apply anti-corrosin oil to the thread and seat of mounting

bolts.

a.

Tighten the bolts in a crisscross fashion to the specified torque.

b.

Tighten the bolts additionally to the specified angle.

Standard

Side gear back clearance

: Refer to

.

When the back clearance

is large:

Use a thicker thrust wash-

er.

When the back clearance

is small:

Use a thinner thrust wash-

er.

PDIA0576E

SPD030

SDIA2594E

Drive gear mounting

bolts tightening torque

: 78.5 N•m (8.0 kg-m, 58 ft-lb)

SDIA0247J